Wiped Film Evaporators

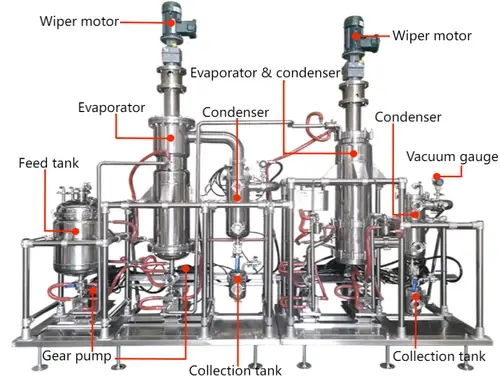

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for Ganoderma lucidum seed oil.

- Product Description

High-Efficiency Wiped Film Evaporators for Precision Separation & Recovery

Wiped Film Evaporators are engineered to deliver unmatched performance in separating heat-sensitive, viscous, or high-purity materials. With over 30 years of expertise, our systems combine advanced thin-film technology, robust 316 stainless steel construction, and ABB automation for precise control. Whether you’re refining ganoderma lucidum seed oil, recovering solvents, or purifying APIs, our solutions minimize thermal degradation while maximizing yield. Let’s explore how these evaporators can optimize your process.

Why Choose Our Wiped Film Evaporators?

- Short Residence Time: Protect heat-sensitive compounds with rapid evaporation cycles.

- High Vacuum Efficiency: Achieve 0.1Pa vacuum levels for superior separation.

- Customizable Designs: Single, dual, or three-stage configurations to match your workflow.

- Global Compliance: CE, ISO, UL, and FDA-certified for pharmaceuticals, food, and hazardous environments.

Applications Across Industries

① Chemical Processing

Recover solvents, distill polymers, or handle corrosive materials with Hastelloy-built evaporators. Our anti-clogging systems reduce downtime in petrochemical refining.

② Pharmaceutical Manufacturing

GMP-compliant units with CIP/SIP capabilities ensure contamination-free API purification.

③ Food & Nutraceuticals

Deacidify oils like ganoderma lucidum seed oil using EC1935-certified systems. Quick-disassembly features simplify sanitation.

④ Waste Management

Safely treat hazardous sludge with ATEX-compliant models designed for high-viscosity waste.

⑤ Bulk Procurement

Distributors benefit from Wiped Film Evaporators white-label options, modular SKUs, and 24/7 technical collaboration.

Technical Specifications

| Parameter | Details |

|---|---|

| Evaporation Area | 0.1–50 m² |

| Materials | SS316, Hastelloy, Titanium |

| Vacuum Range | Up to 0.1Pa |

| Temperature Tolerance | -20°C to 350°C |

| Automation | ABB PLC/SCADA Integration |

Trusted by Global Leaders

✅ 500+ Installations across 30 countries

✅ 98% On-Time Delivery for large-scale projects

✅ 1-Year Warranty + Lifetime Support

Competitive Edge

| Feature | Our WFE | Competitors |

|---|---|---|

| Energy Consumption | 30% Less | Standard |

| Lead Time | 8 Weeks | 12+ Weeks |

| Warranty | 1 Year | 6 Months |

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do the products handle high-viscosity chemicals?

A rotating wiper creates a thin, turbulent film, ensuring even heat distribution and preventing residue buildup—ideal for polymers or heavy oils.

Are your systems compliant with pharmaceutical GMP?

Yes. We use ultra-clean finishes, material traceability, and validation documentation to meet FDA/EU GMP standards.

What food-grade certifications do you offer?

Our units comply with FDA, EC1935, and 3A standards. Optional Halal/Kosher certifications are available.

Can I integrate these evaporators into existing setups?

Absolutely. We design hybrid systems that sync with your solvent recovery or distillation lines.

Contact Us

Tell us your Wiped Film Evaporators requirements:

- Industry: Pharmaceuticals, Chemicals, Food, etc.

- Material Type: Viscous, corrosive, heat-sensitive?

- Capacity: 100L/hr to 10,000L/hr configurations.

Email Your Specs: info@welloneupe.com