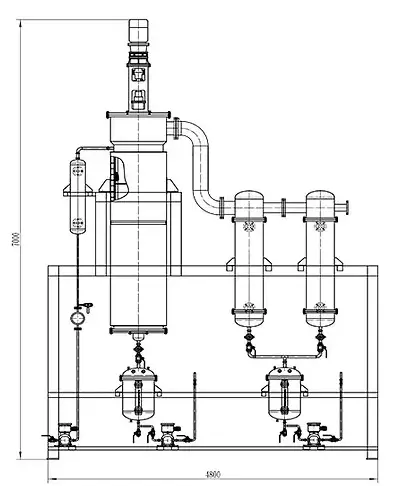

Stainless Steel Agitated Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for polyacid grease.

- Product Description

Stainless Steel Agitated Thin Film Evaporator: Precision Engineering for Demanding Industries

When processing high-viscosity fluids, heat-sensitive compounds, or corrosive materials, efficiency and reliability are non-negotiable. Our Stainless Steel Agitated Thin Film Evaporator delivers unmatched performance in these scenarios, combining advanced agitation technology with corrosion-resistant 316L/304 stainless steel construction. Designed for industries like pharmaceuticals, chemical processing, and food production, this system ensures rapid evaporation, minimal thermal degradation, and compliance with global standards like GMP and ASME.

Why Choose Our Agitated Thin Film Evaporator?

1. Built to Last, Engineered to Perform

Crafted from high-grade stainless steel, our evaporator resists corrosion from aggressive chemicals and abrasive slurries. The agitated thin-film design creates a turbulent flow, enhancing heat transfer rates by up to 30% compared to static evaporators. This means faster processing times and lower energy costs—whether you’re concentrating pharmaceutical APIs or recovering solvents from wastewater.

2. Customizable for Your Unique Needs

Modular configurations: Choose single-stage, dual-stage, or three-stage setups.

Precision control: ABB automation systems ensure ±1°C temperature accuracy.

Sanitary finishes: Mirror-polished surfaces (Ra ≤0.4µm) meet 3-A and EHEDG standards for food and pharma applications.

3. Global Compliance, Local Support

From CE and FDA certifications to ATEX-rated models for explosive environments, our systems adhere to your regional regulations. With service hubs in 20+ countries, we provide rapid technical support and spare parts to minimize downtime.

Applications Across Industries

Chemical Processing

Efficiently handle polymer devolatilization or solvent recovery with our clog-resistant agitators. The stainless steel construction withstands acidic or alkaline media, reducing maintenance costs.

Pharmaceutical Manufacturing

GMP-compliant designs feature CIP/SIP compatibility and validated cleaning protocols to eliminate cross-contamination risks during API production.

Food & Beverage Production

Preserve delicate flavors and nutrients with Stainless Steel Agitated Thin Film Evaporator low-temperature operation under high vacuum (up to 0.1Pa). Ideal for concentrating fruit extracts or dairy products.

Environmental Solutions

Reduce hazardous sludge volume by 80% using hardened rotor blades and anti-fouling coatings. Our systems meet ISO 14001 and NACE standards for corrosive wastewater treatment.

Technical Highlights

- Material: 316/304 stainless steel (options for 904L, Hastelloy).

- Certifications: CE, ISO 9001, 3-A, FDA-compliant.

- Vacuum Range: 0.1Pa–101kPa.

- Temperature Tolerance: -50°C to 300°C.

- Warranty: 1 year (extendable).

Trusted by Industry Leaders

> “Switching to their agitated thin film evaporator cut our energy costs by 30% and reduced batch times by half.”

— Process Engineer, European Pharma Co.

> “The automated scraping system eliminated manual cleaning, saving us 20 hours/month.”

— Plant Manager, North American Chemical Processor

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQs

How does your evaporator prevent fouling in high-viscosity fluids?

The agitated rotor continuously renews the product film, preventing material buildup. Combined with anti-scaling surface treatments, this ensures consistent performance.

Is the system compatible with CIP/SIP protocols?

Yes. All pharma-grade units include hygienic cladding and documentation to streamline validation.

Can you customize alloys for halogenated solvents?

We offer Hastelloy C-276 and titanium coatings for extreme corrosion resistance.

What’s the lead time for bulk orders?

Standard configurations ship in 8–10 weeks. Contact us for expedited options.

Contact Us

Ready to Optimize Your Stainless Steel Agitated Thin Film Evaporator Process?

Email info@welloneupe.com to discuss volume discounts or request a performance simulation tailored to your materials.