Laboratory Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for P-type flexible material.

- Product Description

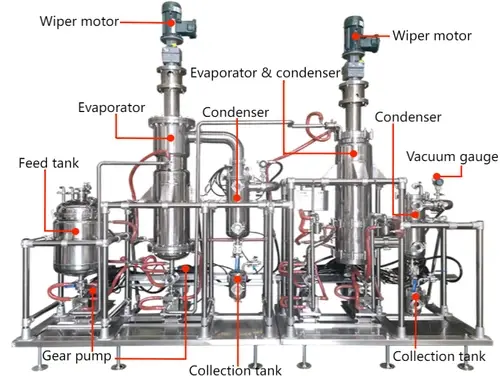

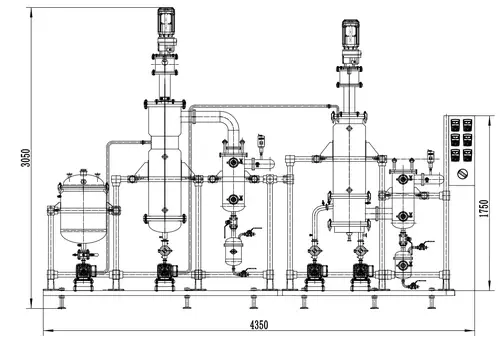

Laboratory Thin Film Evaporator: Precision Separation for Demanding Applications

When handling heat-sensitive compounds or optimizing solvent recovery, a Laboratory Thin Film Evaporator offers unmatched efficiency. Designed for industries requiring high-purity separation—from pharmaceuticals to sustainable tech—our systems combine GMP-ready performance, energy-efficient operation, and scalable configurations. With vacuum levels as low as 0.1Pa and 316 stainless steel construction, you achieve precise results without compromising material integrity.

Why Choose Our Thin Film Evaporation Systems?

1. Advanced Separation Technology

Our evaporators create a uniform thin film of material on heated surfaces, enabling rapid evaporation at lower temperatures. This minimizes thermal degradation—ideal for APIs, essential oils, or reactive polymers. The rotating scraper ensures continuous renewal of the film, boosting throughput even with viscous solutions.

2. Built for Your Industry

Pharma/Biotech: cGMP-compliant designs with CIP/SIP capabilities.

Chemicals: Corrosion-resistant materials (SS 316L, PTFE) for aggressive solvents.

Food/Cosmetics: Sanitary electropolished surfaces to preserve aromas.

Environmental: Closed-loop solvent recovery (up to 95% efficiency).

3. Modular & Scalable

Start with a benchtop unit for R&D (50–500 mL/hr) and scale seamlessly to pilot systems (1–5 L/hr). Swap condensers, feed pumps, or control modules (ABB PLC) as needs evolve.

4. Energy-Smart Design

Reduce operating costs by 40% compared to rotary evaporators. Our systems reclaim solvents efficiently, cutting waste and energy use (≤5 kW).

Key Specifications

| Feature | Detail | |

|---|---|---|

| Vacuum Range | 0.1Pa – 100kPa | |

| Materials | 316 Stainless Steel, Glass, PTFE | |

| Temperature Control | ±1°C Precision | |

| Certifications | CE, ISO 9001, GMP, ASME | |

| Warranty | 1 Year + Lifetime Support |

Solve Critical Workflow Challenges

- Pharmaceuticals: Purify APIs with <99.9% purity, meeting FDA 21 CFR Part 11.

- Essential Oils: Preserve volatile terpenes at ≤40°C operation.

- Nanomaterials: Handle polymer solutions up to 10,000 cP viscosity.

- Hazardous Waste: ATEX-certified explosion-proof options available.

Trusted by Innovators Worldwide

> "Switching to this Laboratory Thin Film Evaporator reduced our solvent costs by 60% and improved batch consistency."

— Lead Chemist, European Pharma Lab

Certified Compliance: CE, ISO 14001, NSF.

Global Support: 24/7 technical assistance, on-site training, and <72hr spare parts delivery.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does a product protect heat-sensitive compounds?

A thin, rapidly renewing film and precise temperature control (<±1°C) prevent overheating.

Can I use this system for food-grade extracts?

Yes—sanitary designs with electropolished surfaces meet NSF/HACCP standards.

What rotor speed is ideal for viscous materials?

Adjustable speeds (100–1200 RPM) handle polymers up to 10,000 cP.

Is scaling from lab to production possible?

Absolutely—modular components ensure identical performance across scales.

How energy-efficient are these systems?

Solar-compatible models cut energy use by 40% vs. traditional evaporators.

Contact Us

Contact Us Today: Tailor a Laboratory Thin Film Evaporator solution for your needs at info@welloneupe.com.