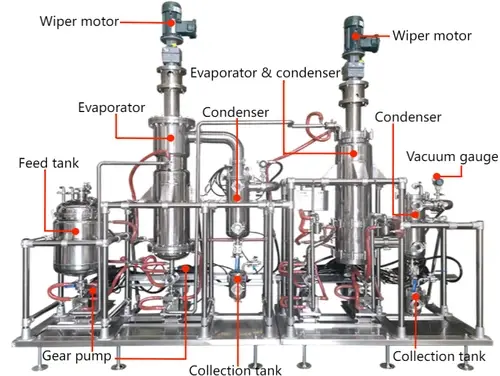

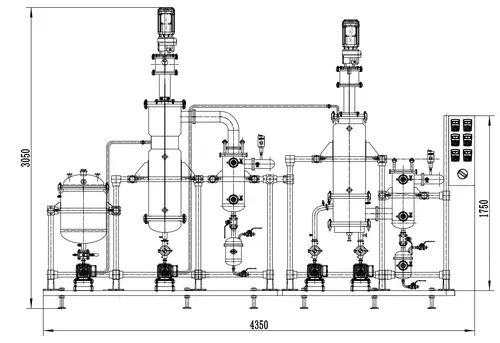

Stainless Steel Falling Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for adhesive.

- Product Description

High-Efficiency Stainless Steel Falling Film Evaporators for Acid, Food, Pharma & ZLD Applications

Key Benefits

- Stainless Steel Falling Film Evaporator with corrosion-resistant 316/304 stainless steel construction

- Energy-efficient evaporation for heat-sensitive materials

- Customizable designs for acids, alkalis, dairy, juices, or wastewater

- Compliant with FDA, ISO, and GMP standards

Product Overview

A product is engineered to deliver rapid, low-temperature concentration of liquids while preserving product integrity. Whether you’re processing aggressive chemicals, heat-sensitive pharmaceuticals, or viscous food syrups, our evaporators ensure minimal energy use and maximum output. Built with 316 stainless steel, they thrive in corrosive environments, making them ideal for industries like chemicals, food processing, and zero liquid discharge (ZLD) systems.

Why Choose Our Stainless Steel Falling Film Evaporator?

1. Precision Engineering for Harsh Environments

From sulfuric acid concentration to dairy syrup thickening, our evaporators use 316-grade stainless steel to resist corrosion and extend equipment life. Optional electropolishing ensures compliance with strict hygiene standards in pharma and food sectors.

2. Energy Savings Up to 30%

Thin-film technology distributes liquids evenly across heated surfaces, reducing thermal degradation and slashing energy costs. A German chemical plant cut OPEX by 24% using our multi-effect configuration.

3. Scalable & Automated Operations

Choose from single-stage to three-stage designs with capacities from 500 to 50,000 L/h. Integrated ABB control systems monitor viscosity, pH, and temperature in real time, ensuring consistent results.

4. Global Compliance, Local Support

Certified for CE, ASME, and FDA standards, our Stainless Steel Falling Film Evaporator units meet regional demands—whether it’s PED compliance in Europe or rapid deployment in Asia. Plus, 24/7 technical support keeps downtime to a minimum.

Industry-Specific Solutions

🧪 Chemical Processing

Concentrate acids (HCl, H2SO4) or recover solvents with leak-proof designs and automated scaling prevention.

🥛 Food & Beverage

Thicken juices, milk, or syrups without nutrient loss. CIP/SIP compatibility simplifies cleaning between batches.

💊 Pharmaceuticals

Gentle evaporation for vaccines and APIs, with GMP-compliant surfaces and ±1°C temperature uniformity.

🌍 ZLD & Desalination

Reduce brine volume by 80% using hybrid MED-TVC configurations, ideal for high-salinity environments.

Technical Specifications

- Material: SS316/SS304 (electropolished options)

- Vacuum Range: 10–500 mbar

- Surface Finish: Ra ≤0.8 µm (food/pharma models)

- Warranty: 1 year (extendable)

Trusted by Global Leaders

BASF, Nestlé, and Veolia rely on our evaporators for:

- 80% energy savings in Middle East desalination projects.

- 95% dry matter output for dairy processors.

- 10-year corrosion warranty on welded joints.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

Q: Can your evaporator handle corrosive acids like sulfuric acid?

A: Yes! The 316 stainless steel construction resists corrosion, even in aggressive chemical environments.

Q: Are your evaporators FDA-compliant for food production?

A: Absolutely. We offer EHEDG-certified models with smooth surfaces (Ra ≤0.8µm) for dairy and juice applications.

Q: How do you prevent scaling in high-salinity environments?

A: Anti-clogging nozzles and pre-coated surfaces minimize fouling in ZLD systems.

Q: What’s the lead time for custom orders?

A: Typically 8–12 weeks. Contact us for expedited options.

Contact Us

Need a Custom Stainless Steel Falling Film Evaporator Solution?

Contact Us: info@welloneupe.com | Global Delivery Available