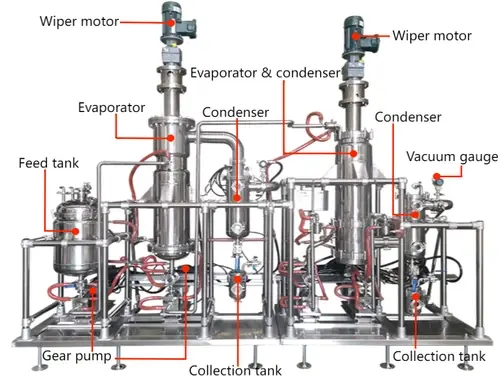

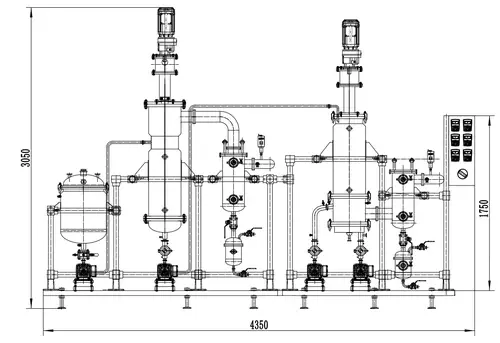

Lab Scale Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for potassium battery additive.

- Product Description

Lab Scale Thin Film Evaporator: Precision Evaporation for Research & Small-Batch Production

When working with heat-sensitive compounds or small-batch processes, precision is non-negotiable. Our Lab Scale Thin Film Evaporator combines compact engineering with industrial-grade performance, delivering unmatched control for academic labs, pharmaceutical startups, and specialty chemical developers. With a high vacuum range (up to 0.1Pa) and corrosion-resistant 316 stainless steel construction, it’s designed to handle everything from potassium battery additives to nanoparticle synthesis.

Why Our Lab-Scale System Stands Out?

- Space-Smart Design: Fits seamlessly into crowded lab benches without sacrificing capacity (0.1–5 L/hr).

- Adjustable Precision: Fine-tune temperature (20°C–200°C), vacuum levels, and rotor speed for diverse materials.

- Scalable Results: Replicate lab conditions in pilot/production systems effortlessly.

- Certified Safety: CE, ISO, and UL certifications ensure compliance with global research and manufacturing standards.

Tailored for Your Industry

Academic & Government Labs

Use Case: Solvent recovery, environmental sample concentration.

Key Feature: ABB control system for publication-grade data repeatability (±1% variance).

Pharmaceutical Startups

Use Case: API purification, solvent recycling for FDA submissions.

Key Feature: cGMP-ready surfaces and batch traceability modules.

Specialty Chemical Manufacturers

Use Case: Gentle separation of fragrances or heat-labile compounds.

Key Feature: Low-temperature operation (<80°C) with anti-fouling Hastelloy options.

CROs & Contract Labs

Use Case: Multi-client process development.

Key Feature: Rapid-swap cassettes and cloud-based analytics for audit-ready workflows.

Technical Specifications

| Parameter | Details |

|---|---|

| Capacity | 0.1–5 L/hr |

| Operating Temperature | 20°C–200°C |

| Vacuum Range | 1–200 mbar (customizable to 0.1Pa) |

| Materials | Glass, SS316, Hastelloy |

| Control System | ABB PLC with touchscreen interface |

Trusted by Innovators

“Switching to this Lab Scale Thin Film Evaporator cut our solvent waste by 40% during API trials. The real-time monitoring is a game-changer.”

– Dr. Elena Rodriguez, Process Chemist, BioPharma Innovations

“We needed a system that could handle both OLED materials and agrochemical prototypes. The customizable rotor speed made it possible.”

– University of Toronto Nanotech Lab

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

Q: Can this system handle high-viscosity materials like agrochemical slurries?

A: Absolutely. The adjustable rotor scraper maintains a uniform thin film, even for viscosities up to 50,000 cP.

Q: What’s the lead time for a custom-configured evaporator?

A: Most orders ship in 6–8 weeks. We provide weekly production updates for full transparency.

Q: Are your systems compatible with explosive atmospheres?

A: Yes, ATEX-certified models are available for hazardous material handling.

Q: How do I prevent cross-contamination in multi-product workflows?

A: We recommend our quick-disassembly kits and CIP (Clean-in-Place) protocols, which reduce cleaning time by 70%.

Contact Us

Experience firsthand how our Lab Scale Thin Film Evaporator can streamline your R&D or small-batch production.

📧 Email: info@welloneupe.com

20+ years of thin film evaporation expertise | ISO 9001-certified manufacturing | Global shipping with local support hubs