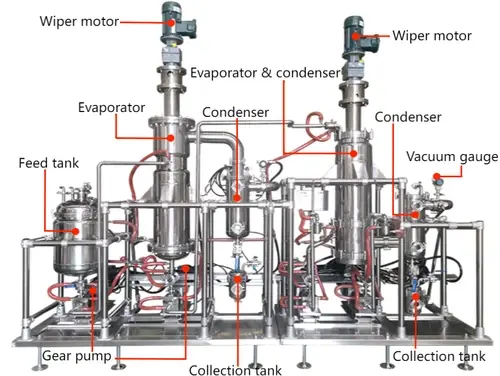

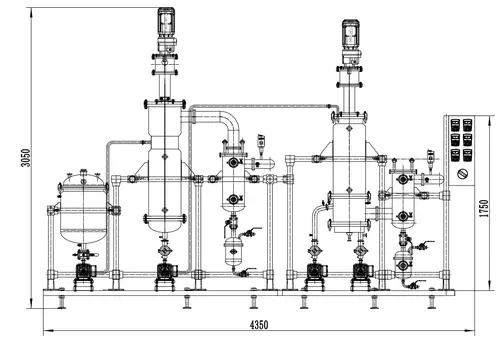

Pilot Wiped Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for VE.

- Product Description

Precision Pilot Wiped Film Evaporators for Scalable Separation Tasks

Compact, GMP-compliant systems for R&D, process optimization, and small-batch production of heat-sensitive compounds.

When working with delicate materials like APIs, essential oils, or specialty chemicals, the Pilot Wiped Film Evaporator offers unmatched precision. Designed for labs and pilot plants, this system combines ultra-thin film evaporation, customizable configurations, and energy-efficient performance to handle viscous, temperature-sensitive, or volatile substances. Whether scaling up R&D results or optimizing solvent recovery, our evaporator ensures consistent purity while minimizing thermal degradation—all within a footprint 30% smaller than traditional systems.

Why Choose Our Pilot Wiped Film Evaporator?

- Advanced Thermal Control: Maintain ±1°C stability across 50°C–300°C, ideal for heat-sensitive compounds.

- Scalable Designs: Transition seamlessly from lab trials (5 kg/hr) to pilot production (50 kg/hr) with modular components.

- GMP & FDA Compliance: 316L stainless steel or Hastelloy construction, validated for pharmaceutical and food-grade applications.

- Energy Savings: Achieve 40% lower energy use vs. rotary evaporators through optimized heat transfer.

- Zero Downtime: Patented wiping mechanism reduces fouling, with 98% uptime in continuous operations.

Tailored Solutions for Your Industry

Pharmaceuticals

Isolate high-purity APIs with ≤50 ppm solvent residuals, meeting ICH Q7 and EU-GMP guidelines.

Chemicals & Polymers

Fractionate fatty acids, silicones, or polymers at 99.9% efficiency, even at viscosities up to 50,000 cP.

Food & Cosmetics

Preserve terpenes, antioxidants, and aromas using low-temperature evaporation (<80°C) in HAACP-certified systems.

Environmental Tech

Treat pyrolysis oils or hazardous waste with a Pilot Wiped Film Evaporator, achieving 95%+ heavy metal removal, ATEX-certified for explosive atmospheres.

Technical Specifications

| Model | Evaporation Area (m²) | Throughput (kg/h) | Vacuum Range (mbar) |

|---|---|---|---|

| WFE-05 | 0.5 | 5–20 | 0.1–800 |

| WFE-10 | 1.0 | 10–50 | 0.1–800 |

All models feature ABB control systems, 316 stainless steel material, and 1-year warranty.

Built for Sustainability

- Recover 98%+ solvents for REACH compliance

- Reduce carbon footprint with 30% lower steam consumption

- Enable zero liquid discharge (ZLD) in wastewater treatment

Global Support, Local Expertise

- 24/7 multilingual support

- 48-hour spare parts delivery

- Onsite training in Germany, USA, and India

Trusted By Leaders

ISO 9001:2015 Certified | CE & ASME Compliant | 15-Year Warranty

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

Q1: How does the product prevent thermal damage to sensitive compounds?

Our evaporator’s short residence time (<30 seconds) and precise temperature control minimize heat exposure.

Q2: Can it integrate with existing PLC/SCADA systems?

Yes—customizable automation protocols ensure seamless plant integration.

Q3: What certifications are available?

CE, ASME, ATEX, ISO 22000, and more, tailored to your region.

Q4: Is the system suitable for edible oil concentration?

Absolutely. We use food-grade polishing (Ra ≤0.4 µm) and kosher/halal-compliant designs.

Q5: How is viscous feedstock handled?

The patented rotor adjusts wiping speed dynamically, maintaining film uniformity up to 50,000 cP.

Contact Us

Limited Availability—Book Your Pilot Wiped Film Evaporator Factory Acceptance Test Today!

Contact Us: info@welloneupe.com