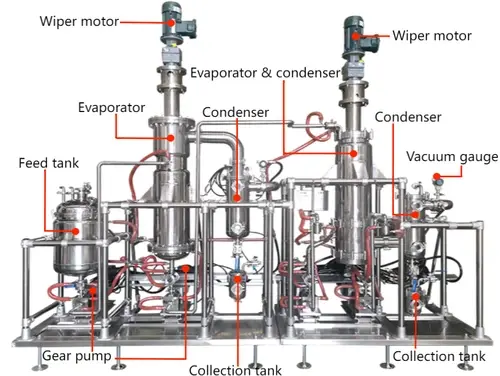

Stainless Steel Wiped Film Evaporator

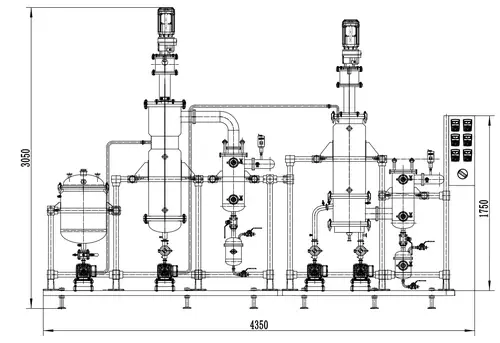

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for waste lubricating oil regeneration.

- Product Description

Stainless Steel Wiped Film Evaporator: Precision Evaporation for Demanding Industries

Engineered for efficiency and durability, our Stainless Steel Wiped Film Evaporator delivers unmatched performance in separating heat-sensitive materials. Built with corrosion-resistant SS316L stainless steel and backed by global certifications (CE, ISO, FDA), this system excels in high-vacuum environments while preserving product integrity. Whether you’re refining pharmaceuticals, concentrating essential oils, or recycling industrial solvents, our evaporator adapts to your needs with customizable configurations and energy-saving designs. [Request Customized Technical Specs]

How It Works: Advanced Evaporation Technology

The product operates on a simple yet powerful principle: a rotating wiper blade spreads materials into a thin, even film across a heated surface. This design ensures:

- Short Residence Time: Minimizes thermal exposure to protect delicate compounds.

- High Vacuum Efficiency: Achieves precise separations at pressures as low as 0.1Pa.

- Low-Temperature Processing: Ideal for heat-sensitive APIs, flavors, and biofuels.

With modular scaling from lab-grade (0.5m²) to industrial (40m²) units, this system handles viscosities from 10 to 50,000 cP without compromising throughput.

Industry-Specific Solutions

Pharmaceuticals & Chemicals

- Purify APIs with 99.8% purity using GMP-compliant SS316L surfaces.

- Devolatilize polymers without thermal degradation.

Food & Essential Oils

- Preserve delicate flavors and nutrients with ±1°C temperature control.

- CIP/SIP-ready designs meet FDA and EHEDG hygiene standards.

Biodiesel & Renewable Energy

- Process viscous feedstocks (e.g., waste cooking oil) with 30% higher yield.

- Integrated heat recovery slashes energy costs by 25%.

Industrial Waste Treatment

- Safely recover VOCs and heavy metals using explosion-proof, PVDF-lined models.

- Achieve zero liquid discharge with closed-loop configurations.

Global Distributors

- White-label, skid-mounted systems with plug-and-play installation.

- CE/UKCA-certified components for seamless regional compliance.

Technical Highlights

| Feature | Specification | |

|---|---|---|

| Material | SS316L, Hastelloy, or PVDF-lined | |

| Evaporation Area | 0.5m² – 40m² | |

| Vacuum Range | ≤1mbar | |

| Temperature Range | -20°C to 400°C | |

| Certifications | ASME, PED, FDA, ISO 9001 |

Why Choose Our Evaporator?

- ✅ 40% Faster Processing vs. traditional falling film evaporators.

- ✅ 5-Year Corrosion Warranty on SS316L components.

- ✅ IoT Monitoring: Real-time tracking of temperature, pressure, and rotor speed.

- ✅ 72-Hour Spare Parts Delivery from regional hubs in the US, EU, and Asia.

Proven Results

- Pharmaceutical Case Study: Achieved 99.8% purity in peptide separation using a Stainless Steel Wiped Film Evaporator for a leading EU manufacturer.

- Biodiesel Application: Reduced energy costs by 30% for a Southeast Asian bio-refinery.

- Food Processing: Enabled a 20% increase in essential oil yield for a Brazilian extractor.

Global Support, Local Expertise

- Multilingual technical support (24/7).

- On-site installation and operator training.

- Compliance guidance for ASME, ATEX, and regional safety codes.

Trusted By

🔹 Fortune 500 Chemical Producers

🔹 TÜV-Certified Performance Reports

🔹 15+ Patents in Wiping System Design

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does your evaporator prevent API degradation?

Our SS316L design ensures uniform thin-film evaporation under high vacuum, reducing thermal stress.

Is this system suitable for dairy concentration?

Yes, FDA-compliant surfaces and CIP compatibility meet strict hygiene standards.

Can it handle waste cooking oil?

Absolutely. High-torque motors and abrasion-resistant wipers process viscosities up to 50,000 cP.

What’s the VOC recovery rate?

Up to 98%, depending on feedstock composition and vacuum settings.

Are regional certifications supported?

Yes. Units ship pre-certified for CE, UKCA, or CRN compliance.

Contact Us

Email: info@welloneupe.com

Let’s optimize your Stainless Steel Wiped Film Evaporator evaporation process with precision-engineered solutions.