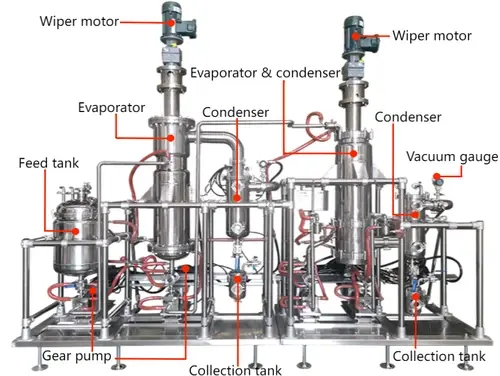

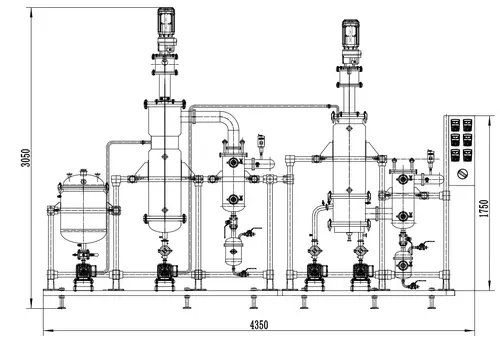

Laboratory Short Path Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for Polyol cool lubricating oil.

- Product Description

Precision Laboratory Short Path Evaporators for Sensitive Material Separation

GMP-Compliant, Modular Systems for R&D to Pilot-Scale Applications

When handling heat-sensitive compounds, every degree matters, and precise temperature control is essential to ensure product integrity. Our Laboratory Short Path Evaporator integrates cutting-edge thermal management with pharmaceutical-grade engineering, enabling highly accurate separations while minimizing thermal degradation. Designed for both researchers and industrial laboratory applications, these versatile systems scale seamlessly from essential oil refinement to complex active pharmaceutical ingredient (API) purification. Built with compliance in mind, they consistently meet strict ISO 9001 and GMP standards, providing reliability, efficiency, and reproducibility for advanced laboratory and small-scale production processes.

Where Innovation Meets Application?

From isolating highly temperature-sensitive cannabinoids to efficiently recovering heavy metals and other valuable compounds, here’s how diverse industries around the world leverage our advanced separation and purification technology for optimal results:

- Pharma/Biotech: Purify APIs with ≤1ppm cross-contamination

- Chemicals: Achieve 98%+ solvent recovery from aggressive hydrocarbons

- Academic Labs: Reproduce results within ±1% evaporation rates

- Environmental: Safely process VOC-laden waste with ATEX-certified designs

Why Engineers Trust Our Systems?

| Feature | Impact |

|---|---|

| 0.001 mbar Vacuum Range | Preserves delicate compounds |

| 316L SS & Borosilicate Glass | Resists corrosion, ensures purity |

| ±0.1°C Temperature Control | Eliminates thermal degradation |

| Self-Cleaning Wiped-Film Design | Reduces downtime by 40% |

Built for Global Compliance

- CE/UKCA Marked

- FDA 21 CFR Part 11 Data Logging

- ATEX Zone 1 Options

- ASME BPVC Sec VIII Pressure Vessels

Tailored to Your Workflow

Configure your ideal Laboratory Short Path Evaporator distillation system:

1. Batch Size: 100mL benchtop units to 20L pilot systems

2. Cold Traps: Standard (-40°C) or cryogenic (-80°C)

3. Automation: Integrate with SCADA/PLC networks

Worldwide Support, Local Expertise

- 24/7 Multilingual Support: English, Spanish, Mandarin, Arabic

- Regional Service Hubs: Quick dispatch from EU/US/Asia warehouses

- On-Site Training: Learn advanced techniques from our engineers

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do you prevent cannabinoid degradation during distillation?

Our dual-zone heating and 15°C thermal gradient control keep materials below critical thresholds.

Can I process chlorinated solvents?

Yes—Hastelloy C276 wetted parts resist even aqua regia mixtures.

Is training included?

All units come complete with detailed video tutorials and step-by-step guidance, along with three full months of dedicated remote support, ensuring users can operate and troubleshoot efficiently.

What’s the ROI for environmental applications?

Clients typically achieve an impressive 18-month payback period by implementing our systems, which consistently deliver up to 80% energy recovery rates, significantly reducing operational costs.

Contact Us

Contact Our Engineers about the Laboratory Short Path Evaporator at info@welloneupe.com.