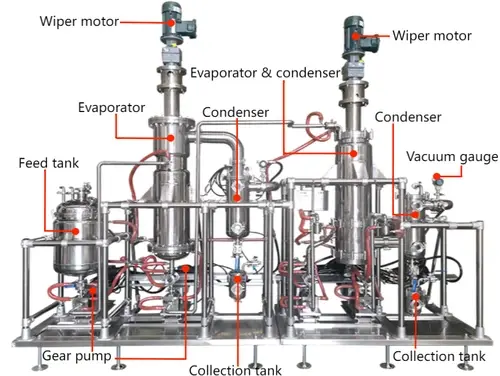

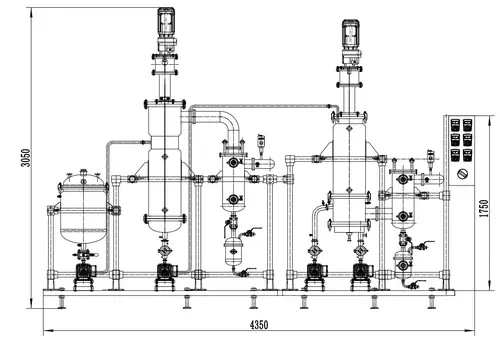

Stainless Steel Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for Epoxy resin.

- Product Description

High-Performance Stainless Steel Thin Film Evaporators for Precision Separation & Recovery

Engineered for Corrosion Resistance, GMP Compliance, and Energy Efficiency Across Industries

Industries requiring precise separation and recovery of sensitive materials trust Stainless Steel Thin Film Evaporators for their unmatched durability and thermal efficiency. Built with 316/316L stainless steel, our evaporators excel in aggressive chemical, pharmaceutical, and food-grade applications. From solvent recovery to heat-sensitive extract concentration, our systems minimize thermal degradation while maximizing energy savings.

Why Choose Our Stainless Steel Thin Film Evaporators?

Advanced Technology for Demanding Environments

- Short Residence Time: Reduces thermal stress on delicate compounds like APIs or natural extracts.

- Low Leakage Design: ≤0.5% leakage rate ensures minimal product loss in high-value applications.

- Multi-Stage Configurations: Single, dual, or three-stage setups for batch/continuous processing.

Industry-Tailored Benefits

- Chemical/Petrochem: ATEX-compliant models handle solvents with >99% recovery rates.

- Pharma: Electropolished surfaces (Ra ≤0.4μm) and FDA-compliant documentation packages.

- Food & Beverage: EHEDG-certified crevice-free welds prevent bacterial growth.

- Waste Treatment: Duplex stainless steel options resist acidic/alkaline corrosion.

Key Specifications

| Parameter | Specification |

|---|---|

| Material | 316/316L Stainless Steel |

| Heating Surface | 0.5–50 m² (modular expandable) |

| Vacuum Range | Down to 0.1 Pa |

| Temperature Range | -20°C to 200°C (PID-controlled) |

| Certifications | CE, ISO 9001, ASME, FDA 21 CFR Part 11 |

Trusted Across Critical Applications

Chemical Processing

Concentrate epoxy resins or distill heat-sensitive monomers without degradation.

Pharmaceutical Manufacturing

GMP-compliant API concentration with full IQ/OQ/PQ validation support.

Food Production

Gentle concentration of citrus oils or dairy extracts at ≤0.1°C precision.

Environmental Remediation

Recover VOCs from industrial sludge with 90%+ thermal efficiency.

Compliance & Quality Assurance

- Material Traceability: Mill test reports for every component.

- Certifications: CE, RoHS, NSF, ISO 13485, and regional pressure vessel codes.

- Testing: Helium leak testing, 3D laser alignment, and FAT protocols.

What Clients Say?

"Switching to their Stainless Steel Thin Film Evaporator cut our energy costs by 40% versus rotary models while meeting EMA audit requirements effortlessly."

– Pharma Production Manager, Germany

"Their team customized a high-viscosity model that eliminated fouling in our natural extract lines."

– Food Processing Plant, Brazil

Custom-Built for Your Workflow

- OEM/ODM Support: Rebrandable control panels (ABB/Siemens) and flange adaptations.

- Retrofit Kits: Integrate with existing distillation columns or CIP systems.

- IoT-Ready: Optional remote monitoring via Modbus TCP/IP.

Global Support Network

- 24/7 Technical Assistance: Multilingual engineers via email/chat/phone.

- Fast Shipping: EXW, FOB, or DDP terms with hazardous material certification.

- Warranty: 1-year coverage with lifetime maintenance support.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

What stainless steel grades do you use for corrosive chemical applications?

Our evaporators use 316/316L SS with precision welding to resist acids, alkalis, and chlorides.

Can these handle high-viscosity pharmaceutical slurries?

Yes! Adjustable rotor speeds (10-1000 RPM) maintain thin-film flow even with 50,000 cP materials.

Is the surface finish suitable for GMP zones?

Absolutely. Electropolishing achieves Ra ≤0.4μm surfaces, exceeding FDA sanitary standards.

How do you prevent flavor carryover in food processing?

Crevice-free welds and CIP/SIP compatibility ensure <0.01% residual product between batches.

What energy recovery features are included?

Optional thermal oil loops or steam recompression cut operating costs by up to 60%.

Do you provide distributor training?

Yes. We offer on-site commissioning support and troubleshooting webinars quarterly.

Contact Us

Optimize Your Stainless Steel Thin Film Evaporator Separation Workflow in 72 Hours

Contact: info@welloneupe.com