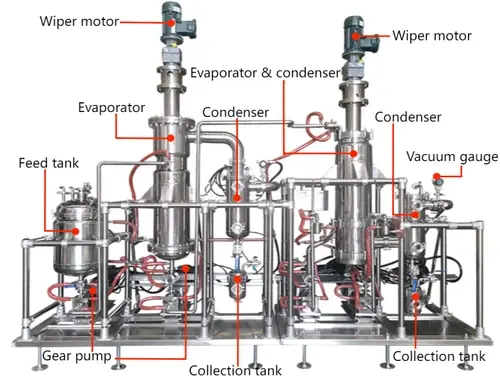

Short Path Molecular Distillation Wiped Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for plasticizer.

- Product Description

High-Purity Short Path Molecular Distillation Wiped Film Evaporators | GMP-Compliant & Energy-Efficient

Optimize heat-sensitive compound separation for APIs, biofuels, natural extracts, and R&D with ≤0.1% residue and 30% faster processing.

When precision matters, our Short Path Molecular Distillation Wiped Film Evaporator delivers unmatched separation efficiency for sensitive materials. Designed to handle everything from pharmaceutical intermediates to viscous biofuels, this system combines ultra-thin film technology with industrial-grade durability. You’ll achieve purities exceeding 99.9% while cutting energy costs by up to 40% compared to conventional evaporators.

Why Choose Our Wiped Film Evaporators?

Advanced Separation Technology

- Ultra-Short Thermal Exposure: Materials spend <1 second in heated zones, preserving delicate compounds like cannabinoids and vitamins.

- Vacuum Precision: Operate at pressures down to 0.001 mbar, enabling low-temperature distillation even for high-boiling-point substances.

- Corrosion-Resistant Construction: Pharma-grade 316L stainless steel and HASTELLOY® surfaces ensure purity and longevity in harsh environments.

Built for Your Industry

- Pharmaceuticals: Purify APIs, recover solvents, and remove impurities under full GMP compliance.

- Natural Oils: Preserve terpenes and CBD integrity with inert gas purging and cold traps.

- Biofuels: Process heavy pyrolysis oils without fouling, thanks to high-shear wipers and ATEX-certified designs.

- Research Labs: Scale experiments seamlessly using modular configurations and real-time data logging.

Technical Specifications

| Parameter | Specification |

|---|---|

| Evaporation Rate | 5–200 kg/h |

| Temperature Range | Ambient to 350°C |

| Vacuum Pressure | 0.001–10 mbar |

| Material Certification | ASME, PED, EHEDG |

| Motor Power | 0.37–55 kW |

| Certifications | CE, ISO 9001/13485, GMP, RoHS, ATEX |

Customization Options

Tailor your Short Path Molecular Distillation Wiped Film Evaporator to match exact needs:

- Scalable Designs: Choose from 0.1 m² lab units to 50 m² industrial systems.

- Automated Controls: ABB PLCs with CIP/SIP compatibility for pharma applications.

- Material Upgrades: Glass-lined surfaces or nickel alloys for aggressive chemicals.

Trusted by Global Leaders

“We achieved 99.8% API purity on the first run, reducing validation time by 6 weeks.”

– Pharmaceutical Manufacturer, Germany

“Yield increased 30% versus rotary evaporators, with zero thermal degradation.”

– CBD Extraction Company, Canada

Wiped Film vs. Traditional Methods

| Feature | Our System | Rotary Evaporators | Falling Film Systems |

|---|---|---|---|

| Thermal Degradation | <0.1% | Up to 15% | 3–8% |

| Throughput (kg/h) | 5–200 | 1–50 | 10–100 |

| Energy Efficiency | 40% savings | Standard | 15% savings |

| Maintenance Interval | 6–12 months | Monthly | Quarterly |

Global Support & Services

- 24/7 Remote Monitoring: IIoT-enabled diagnostics predict maintenance needs.

- On-Site Training: Learn optimal vacuum settings, feed rates, and cleaning protocols.

- Rapid Spare Parts: Critical components shipped worldwide within 48 hours.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does this system comply with GMP standards for pharmaceutical use?

Our product uses 316L stainless steel, validated CIP/SIP cycles, and full documentation packs for FDA/EU audits.

Can it handle high-viscosity bio-oils without clogging?

Yes. Heavy-duty scrapers and hardened rotor blades process feedstocks up to 50,000 cP while minimizing residue buildup.

Is lab-to-production scaling supported?

Absolutely. Pilot units (5 L/h) share the same core tech as industrial models, ensuring seamless scale-up with data-backed parameters.

What’s the lead time for a custom system?

Standard configurations ship in 8–12 weeks. Fully customized builds require 14–18 weeks, including factory acceptance testing.

Contact Us

Ready to Elevate Your Short Path Molecular Distillation Wiped Film Evaporator Separation Process?

Contact Us Today: info@welloneupe.com