12 Inch Wiped Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for carotene.

- Product Description

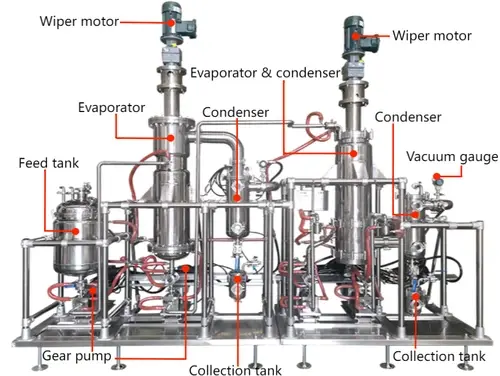

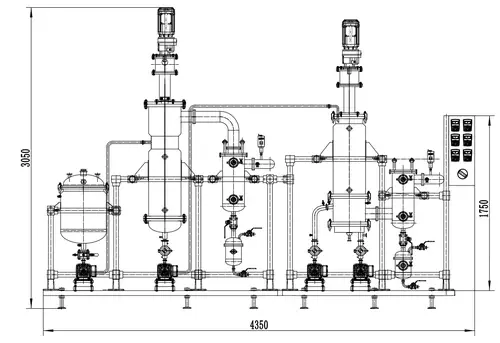

Precision 12 Inch Wiped Film Evaporator for Heat-Sensitive & High-Viscosity Separation

When processing heat-sensitive compounds like carotene, polymers, or essential oils, every second counts. The 12 Inch Wiped Film Evaporator combines ultra-short residence time (<30 seconds) with precision temperature control to minimize thermal degradation while maximizing separation efficiency. Designed for industries ranging from pharmaceuticals to petrochemicals, this system ensures consistent output for viscous feeds, high-purity recovery, and compliance with global standards like GMP and ASME.

Key Benefits of Our 12 Inch Wiped Film Evaporator

- Preserve Delicate Compounds: Gentle evaporation at low temperatures protects APIs, terpenes, and volatile extracts.

- Handle High-Viscosity Feeds: Process heavy oils, waxes, or sludge up to 10,000 cP without clogging.

- Energy Recovery Options: Reduce operational costs by up to 30% with integrated heat exchangers.

- Corrosion-Resistant Build: Choose SS316L, titanium, or nickel alloys for aggressive chemicals.

- Easy Scalability: Modular designs adapt to batch or continuous workflows, from pilot trials to full production.

Technical Specifications

- Evaporation Surface: 12” diameter, 0.5–4 m² (customizable)

- Vacuum Range: 0.001–500 mbar

- Max Temperature: 350°C

- Material: SS316L (standard), Hastelloy, titanium

- Certifications: CE, ISO, GMP, ASME, ATEX

- Warranty: 1 year (extendable)

Who Uses This System?

- Pharmaceutical Manufacturers: Purify APIs with CIP/SIP-ready, GMP-compliant units.

- Essential Oil Producers: Preserve fragrance profiles in cannabis or botanical extracts.

- Petrochemical Plants: Separate heavy hydrocarbon residues with anti-fouling rotor designs.

- Environmental Firms: Recover solvents from wastewater with <5 ppm residuals.

Industry-Specific Solutions

Pharmaceuticals

- Electropolished surfaces, FDA-compliant seals.

- 21 CFR Part 11 data logging for audit trails.

Petrochemicals

- ATEX-rated motors for explosive environments.

- Pre-heat exchangers for faster processing of bitumen.

Essential Oils

- Glass-lined components to prevent contamination.

- Rapid cold traps for terpene preservation.

Why Choose Us?

With 15+ years in thin-film evaporation technology, we’ve optimized the 12 Inch Wiped Film Evaporator for reliability and ROI:

- End-to-End Support: From feasibility analysis to 24/7 technical assistance.

- Proven Performance: 40% less product degradation vs. traditional evaporators (client-verified).

- Global Compliance: Meet ASME, PED, and ISO 22000 requirements effortlessly.

What Clients Say

“This system reduced our carotene processing time by 50% without compromising purity.” – Biofuel Producer, Germany

“Zero cross-contamination in 2 years of continuous API runs.” – Pharma QA Manager, USA

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does the product prevent thermal damage to sensitive extracts?

Its thin-film design limits material exposure to heat, while precise temperature control (±1°C) ensures gentle separation.

Can it handle cannabis distillates with high terpene content?

Yes. Rapid evaporation and cold traps preserve volatile compounds effectively.

What materials are available for corrosive chemical processing?

SS316L, Hastelloy, and titanium options resist acids, solvents, and aggressive feeds.

Is the system compatible with existing solvent recovery setups?

Absolutely. We provide flanges, piping, and control integrations for seamless retrofitting.

What certifications are included for pharmaceutical use?

GMP compliance, FDA 21 CFR Part 11, and full validation documentation.

Contact Us

Need a 12 Inch Wiped Film Evaporator solution for high-viscosity separation? Let’s discuss your project: info@welloneupe.com.