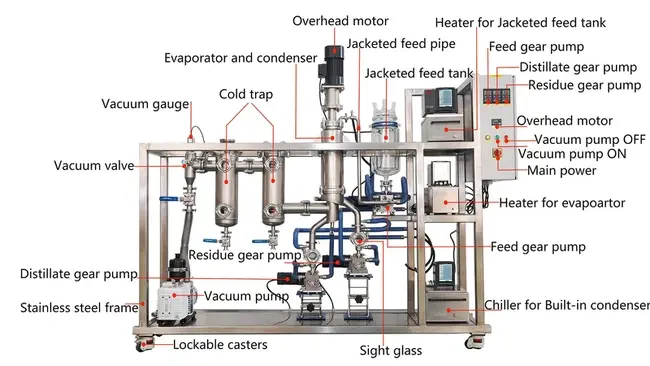

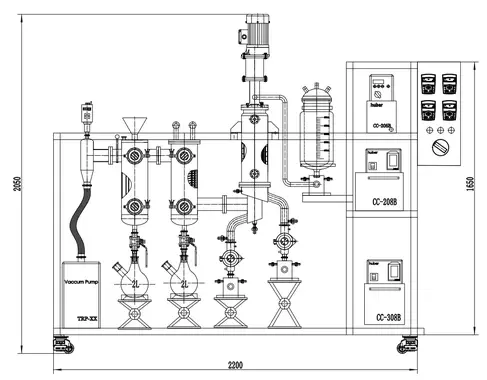

Wiped Film Vacuum Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) simple operation

- Product Description

Precision Separation Redefined: Wiped Film Vacuum Distillation Systems for Industrial Excellence

In high-purity chemical processing, Wiped Film Vacuum Distillation (WFVD) systems have become the gold standard for separating heat-sensitive compounds without degradation. Our advanced WFVD technology operates at 0.1Pa vacuum levels, using mechanically agitated thin-film evaporation to achieve >99.9% purity across pharmaceuticals, biofuels, and specialty chemicals. With 20+ years of engineering expertise, we deliver ISO 9001-certified systems that reduce energy costs by 30-50% while handling viscosities up to 50,000 cP.

Why Choose Our Wiped Film Vacuum Distillation Systems?

✅ Low-Temperature Efficiency

Preserve APIs, terpenes, and fragile compounds with ≤5s residence time at controlled temperatures (<80°C).

✅ GMP/ISO-Compliant Designs

Electropolished SS316L surfaces, CIP/SIP integration, and full validation support (IQ/OQ/PQ) for pharma-grade operations.

✅ Heavy-Duty Performance

Process abrasive pyrolysis oils or polymer melts using Hastelloy wipers and ASME-certified evaporators.

✅ Scalable Modular Configurations

From 50L/hr lab units to 5,000L/hr production systems – replicate results with 1:1000 scaling accuracy.

Industry-Specific Solutions

🧪 Pharmaceuticals & Nutraceuticals

- Purify heat-labile APIs while maintaining potency

- Remove residual solvents from extracts (≤10 ppm)

- Sanitary designs compliant with FDA 21 CFR Part 11

⚡ Biofuel & Renewable Energy

- Refine waste oils into ASTM D6751-compliant biodiesel

- Remove sulfur/contaminants from pyrolysis liquids

- Integrated heat recovery cuts OPEX by 40%

🌿 Essential Oils & Botanicals

- Concentrate CBD isolates at 95%+ purity

- Remove pesticides from botanical extracts

- Glass viewing ports for visual quality control

🔬 R&D & Pilot Plants

- Benchtop units with open-architecture PLCs

- Interchangeable components for multi-phase testing

Technical Specifications

| Parameter | Specification |

|---|---|

| Evaporation Rate | 50–5,000 L/hr |

| Vacuum Range | 0.1–10 mbar |

| Material Compatibility | SS316L, Hastelloy, Glass |

| Temperature Control | ±1°C |

| Certifications | ISO 9001, GMP, ASME, CE |

Trusted by Global Leaders

Case Study: Petrochemical Giant

A Middle Eastern refinery achieved 99.5% pure lubricant base oils using our Wiped Film Vacuum Distillation (WFVD) system, reducing thermal degradation by 78% compared to rotary evaporation.

Case Study: Pharma Innovator

European manufacturer scaled API purification from lab to commercial batches in 6 months using our modular WFVD units, cutting validation time by 50%.

WFVD vs Traditional Methods

- Thermal Degradation: 5x less than falling film evaporators

- Energy Use: 35% lower than short-path distillation

- Throughput: 2x higher than centrifugal systems

Global Support Network

🔧 <12-hour remote diagnostics

📦 On-demand spare parts inventory

🎓 Operator training programs

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does WFVD prevent thermal damage to sensitive compounds?

Our systems limit material exposure to <5 seconds through optimized rotor speeds and vacuum-controlled evaporation paths.

Can I upgrade a lab-scale WFVD unit to production capacity?

Yes – our modular designs enable seamless capacity expansion using standardized evaporator stacks.

What makes your wiper blades suitable for corrosive chemicals?

We use Hastelloy C-276 blades with patented anti-fouling coatings, tested against HCl/H2S environments.

Do you provide cleaning validation protocols?

Full documentation pack includes swab test templates and microbial sampling points for GMP audits.

How quickly can you deploy emergency service?

94% of critical issues resolved remotely within 8 hours via our real-time PLC monitoring platform.

Contact Us

Email at info@welloneupe.com to learn about Wiped Film Vacuum Distillation.