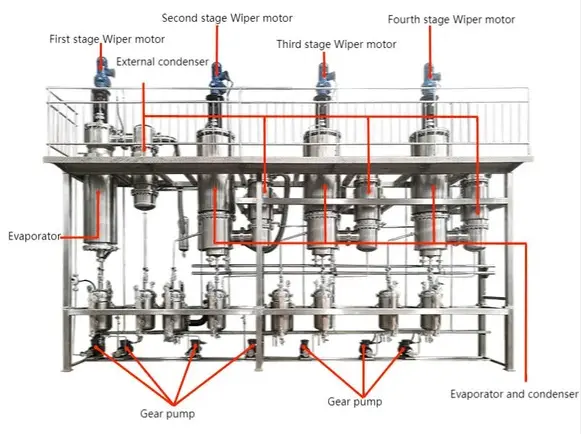

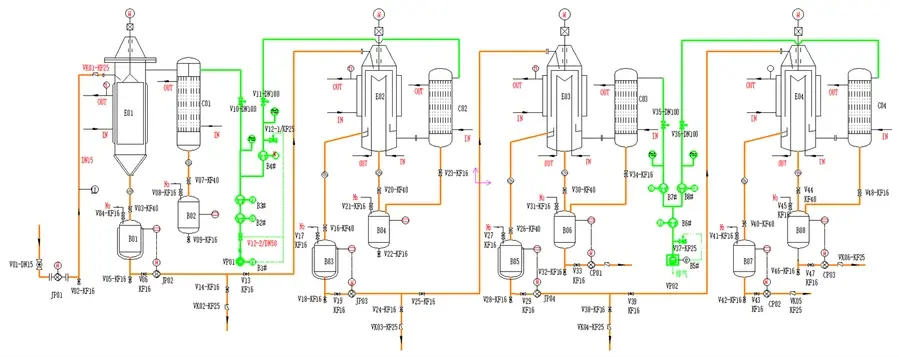

Industrial Wiped Film Molecular Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Automatic Control System

- Product Description

Industrial Wiped Film Molecular Distillation Systems

High-Purity Separation for Heat-Sensitive Materials | CE/ASME Certified | Global OEM Support

Industrial Wiped Film Molecular Distillation is the gold standard for separating thermally sensitive compounds with precision. Combining advanced wiped-film technology and high vacuum (up to 0.1Pa), our systems ensure minimal thermal degradation while handling materials with viscosities up to 50,000 cP. Whether refining APIs, purifying essential oils, or processing biofuels, this method delivers unmatched separation efficiency (>90%) and scalability from pilot-scale trials to full production (5L–5000L).

Why Choose Our Systems?

✅ Low Thermal Degradation: Gentle processing below 80°C preserves bioactive compounds.

✅ High-Viscosity Handling: Robust wipers maintain efficiency even with thick feedstocks.

✅ Modular Design: Customize evaporation areas, condensers, and automation (ABB controls).

✅ Global Compliance: CE, ISO, ASME, and FDA-certified builds for seamless integration.

Industry-Specific Solutions

Pharmaceuticals & Chemicals

- Purify heat-sensitive APIs without solvent residues.

- Achieve >99% purity in vitamin E or cannabinoid distillation.

Natural Extracts & Essential Oils

- Retain volatile terpenes and aromas with short-path configurations.

- Integrated cold traps reduce compound loss.

Biofuels & Renewable Energy

- Process pyrolysis oils with anti-coking designs.

- Reduce energy costs by 40% via pre-heat recovery modules.

Research & Pilot Plants

- Scalable systems for R&D-to-production transitions.

- ±0.5°C temperature control for method development.

Technical Specifications

| Parameter | Specification |

|---|---|

| Evaporation Area | 0.1㎡ – 35㎡ |

| Operating Pressure | 0.1Pa – 5Pa |

| Temperature Range | 50°C – 350°C |

| Material Compatibility | 316L Stainless Steel, Hastelloy, Glass |

| Feed Viscosity Limit | Up to 50,000 cP |

Trusted by Global Leaders

- Case Study 1: A European chemical manufacturer achieved 99% vitamin E purity using our Industrial Wiped Film Molecular Distillation dual-stage system.

- Case Study 2: A biodiesel plant in Brazil cut energy costs by 40% with continuous operation.

Your Success, Our Commitment

- 24/7 Support: Multilingual technical assistance and rapid spare parts delivery.

- End-to-End Service: From feasibility studies to operator training.

- Sustainable Design: Energy-efficient systems with solvent recovery options.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does the product protect heat-sensitive compounds?

The wiped-film mechanism creates a thin material layer, enabling rapid evaporation under high vacuum. This reduces heat exposure by 60% compared to traditional methods.

Can it handle viscous bio-oils for biodiesel refining?

Yes. High-torque wipers and corrosion-resistant surfaces ensure smooth processing of materials up to 50,000 cP.

What certifications do your systems hold?

All units meet CE, ASME, and ISO 9001 standards. Customizable for FDA, GMP, or ATEX compliance.

Do you offer pilot-scale systems for R&D?

Absolutely. Our bench-top models include API-compatible software for seamless data logging.

How long is the warranty?

A 1-year warranty is standard, extendable to 10 years with preventive maintenance plans.

Contact Us

Ready to Optimize Your Industrial Wiped Film Molecular Distillation Process?

📧 Contact us at info@welloneupe.com for a free feasibility study or technical brochure.