Molecular Distillation Machine

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Automatic feeding and collecting

- Product Description

High-Purity Separation for Sensitive Compounds with Our Molecular Distillation Machine

When precision matters, our Molecular Distillation Machine delivers unmatched performance for industries requiring ultra-pure separation of heat-sensitive materials. Designed with proprietary technology, this system ensures minimal thermal degradation, high throughput, and compliance with global standards—making it the go-to solution for pharmaceuticals, biofuels, food production, and more. Whether you’re refining APIs, concentrating omega-3s, or recovering solvents, our machine adapts to your needs seamlessly.

Target Industries & Applications

Our molecular distillation systems are engineered for:

- Pharmaceuticals: Purify APIs (>99.9% purity) without compromising heat-sensitive compounds.

- Essential Oils & Nutraceuticals: Preserve terpenes and bioactive compounds at low temperatures (<100°C).

- Biofuels: Efficiently remove glycerol from high-viscosity feedstocks like waste cooking oil.

- Food & Beverage: Concentrate omega-3s and flavors while meeting FDA 21 CFR and EU 1935/2004 standards.

- Waste Management: Recover 95%+ solvents and process hazardous materials safely.

Technical Specifications

| Parameter | Specification |

|---|---|

| Vacuum Level | 0.1 Pa (High vacuum for precise separation) |

| Material | 316L/304 Stainless Steel (Electropolished) |

| Throughput | 50L/h to 2000L/h (Scalable) |

| Automation | ABB Control System, PLC/HMI Integration |

| Certifications | CE, ISO, FDA, GMP, ATEX, ASME |

Why Choose Our Molecular Distillation Systems?

Compliance & Certifications

All systems meet cGMP, FDA, and CE standards, with options for Halal/Kosher compliance. Our ASME-certified pressure vessels ensure safety in explosive environments (ATEX).

Customization Options

- Modular Designs: Single-stage, dual-stage, or three-stage configurations.

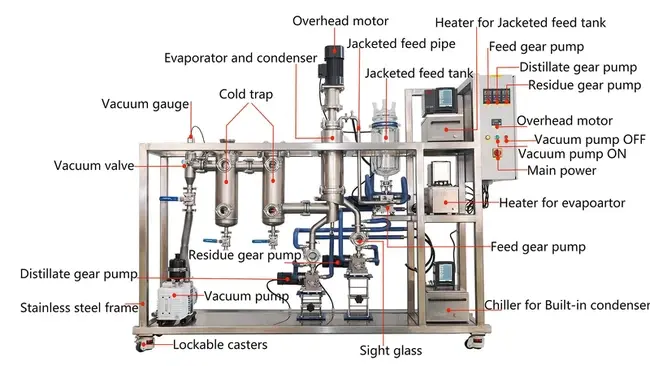

- Add-Ons: Cold traps, nitrogen purging, CIP/SIP compatibility.

- Scalability: Adjust throughput and automation levels for small batches or continuous production.

Sustainability & Cost Efficiency

- Reduce steam consumption by 30% with energy-efficient designs.

- Achieve 95%+ solvent recovery rates, minimizing waste and operational costs.

Global Support & Service

From installation to lifetime maintenance, we provide:

- 24/7 Remote Monitoring: Real-time troubleshooting and optimization.

- On-Site Training: Ensure your team operates the system at peak efficiency.

- Spare Parts Guarantee: 48-hour global delivery for critical components.

Trusted by Industry Leaders

“Their molecular distillation machine boosted our omega-3 yield by 25% while cutting energy costs.” – European Nutraceutical Producer

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does your product handle high-viscosity feedstocks?

Our systems include robust wiper mechanisms and pre-heating stages to process viscous materials like biodiesel feedstocks without clogging.

Can it comply with food-grade standards?

Yes. We use electropolished 316L stainless steel and oxygen-free environments to meet FDA and EU food safety requirements.

What’s the maintenance schedule?

Routine checks every 500 operational hours, with AI-driven predictive maintenance alerts to minimize downtime.

Do you offer small-batch systems?

Absolutely. Our modular designs scale from 50L/h pilot units to 2000L/h industrial plants.

Contact Us

Ready to Elevate Your Molecular Distillation Machine Production?

Contact Us: Email info@welloneupe.com for technical specs or a live demo.

Optimize your process with precision-engineered molecular distillation technology. Let’s build your solution.