Ready to Elevate Your Vacuum Distillation Set Process?

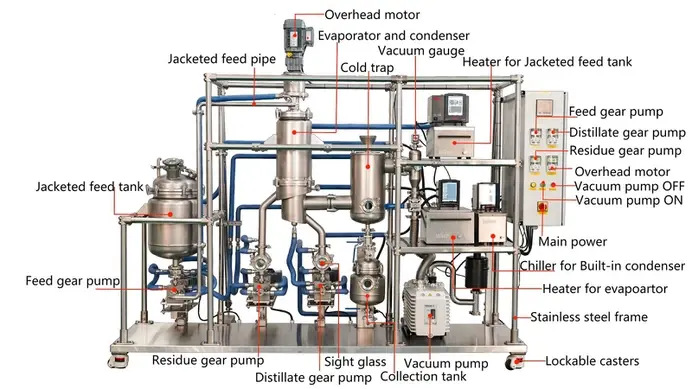

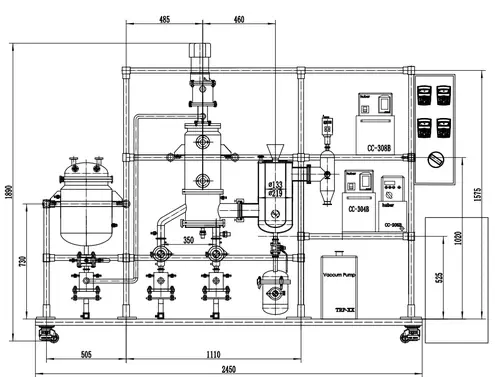

Vacuum Distillation Set

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) overseas install / training service

- Product Description

Vacuum Distillation Set: High-Efficiency Vacuum Distillation Systems for Purity-Critical Industries

Optimize Your Process with Precision & Reliability

When purity and efficiency matter, our Vacuum Distillation Set delivers unmatched performance for industries requiring precise separation of complex mixtures. Designed with proprietary technology and decades of expertise, these systems minimize thermal degradation, reduce energy costs, and scale seamlessly from lab trials to full production.

Why Choose Our Vacuum Distillation Systems?

- Certified Quality: CE, ISO, UL, and SGS certifications guarantee compliance with global safety and performance standards.

- Advanced Materials: Built with 316 stainless steel, Hastelloy, or glass-lined components for corrosion resistance.

- Flexible Configurations: Single-stage, dual-stage, or three-stage setups tailored to your throughput needs.

- Smart Control: ABB automation ensures precise temperature, pressure, and vacuum control (up to 0.1Pa).

- Global Support: 24/7 technical assistance, on-site training, and 1-year warranty included.

Technical Specifications

| Feature | Details |

|---|---|

| Vacuum Range | 0.1Pa – 100kPa |

| Temperature Tolerance | -50°C to 300°C |

| Materials | 316L SS, Hastelloy, PTFE, Borosilicate Glass |

| Capacity | 5L (lab) to 50,000L (industrial) |

| Compliance | ASME, GMP, ATEX, FDA, EPA |

Industry-Specific Solutions

🧪 Pharmaceuticals

- Preserve heat-sensitive APIs with low-temperature solvent recovery.

- CIP/SIP-ready designs eliminate cross-contamination risks.

⚡ Oil & Gas

- Process heavy residues efficiently using explosion-proof, high-pressure setups.

- Automated fouling control reduces downtime.

🌱 Environmental

- Recover >95% reusable solvents from hazardous waste streams.

- Emission scrubbers ensure compliance with EPA/REACH regulations.

🔬 Research Labs

- Compact, modular units with AI-driven data logging for R&D scalability.

Customization Options

- Modular Designs: Add pre-heaters, condensers, or fraction collectors.

- Material Upgrades: Choose glass-lined or PTFE-coated parts for aggressive chemicals.

- Automation: Integrate PLC/DCS for real-time monitoring and batch optimization.

Trusted by Global Leaders

> “Switching to this Vacuum Distillation Set cut our energy use by 30% and doubled batch purity.”

— Chemical Manufacturing Co., Germany

> “The pharma-grade setup streamlined our API isolation process with 99.9% consistency.”

— Top 10 Pharma Brand, USA

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

1. How does a product improve separation for high-boiling materials?

Our systems maintain stable vacuum levels (down to 0.1Pa), lowering boiling points and preventing thermal cracking.

2. Are these systems suitable for corrosive hydrocarbon processing?

Yes! Opt for 316L stainless steel or Hastelloy configurations for corrosive residues.

3. Can I scale from lab to production without re-engineering?

Absolutely. Modular designs allow seamless capacity upgrades.

4. Do you comply with pharmaceutical GMP standards?

Yes. Our systems include documentation for FDA/EU GMP audits.

Contact Us

Contact Us Today

📧 Email: info@welloneupe.com