Glass Wiped Film Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) online vedio talking available

- Product Description

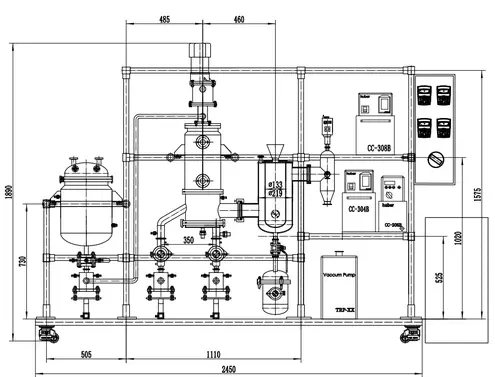

Precision Glass Wiped Film Distillation Systems for Heat-Sensitive Material Processing

GMP/ISO-Certified, Scalable Solutions for APIs, Essential Oils, Biofuels & R&D – Engineered for ≤1ppm Impurity Retention

Whether you’re purifying pharmaceutical intermediates, preserving delicate terpenes in essential oils, or optimizing biodiesel yields, Glass Wiped Film Distillation offers unmatched precision. Our systems combine borosilicate glass clarity with industrial-grade durability to handle materials prone to thermal degradation. With CE, ISO, and ASME certifications, we deliver separation accuracy down to 0.1Pa vacuum levels while reducing energy costs by 30%.

Why Choose Our Glass Wiped Film Distillation Systems?

- Zero-Contamination Design: Borosilicate glass & 316L stainless steel ensure chemical inertness for GMP/FDA-compliant processes.

- Adaptable to Viscous Materials: Handle viscosities up to 0.1Pa·s with PLC-controlled wipers (200–1200 RPM) for consistent thin-film formation.

- Modular Scalability: From lab-scale 5L/hr R&D units to 2000L/hr production systems – scale without redesigning workflows.

- Energy Recovery Technology: Integrated thermal oil loops and short-path condensers cut steam consumption by 40%.

- CIP/SIP Ready: Automated cleaning validation meets EMA Annex 11 and WHO GMP standards.

Technical Specifications

| Parameter | Specification |

|---|---|

| Operating Temperature | 50°C–300°C (±1°C) |

| Vacuum Range | 0.001–1013 mbar (Hybrid Pump System) |

| Material Options | Borosilicate Glass, Hastelloy C-22, PTFE |

| Certifications | CE, ISO 9001:2015, ASME, RoHS |

| Warranty | 3 Years on Thermal Components |

Industry-Specific Solutions

Pharmaceuticals

Purify heat-sensitive APIs with ≤0.5% thermal degradation, achieving ICH Q3C residual solvent limits.

Essential Oils

Preserve 99.9% terpene profiles in citrus oils and cannabinoids through low-temperature molecular distillation.

Biofuels

Process waste cooking oil into ASTM D6751-compliant biodiesel at 1.5m²/kg yield rates.

Specialty Chemicals

Recover high-purity monomers (<1ppm metal ions) using corrosion-resistant Hastelloy wipers.

Trusted by Global Innovators

Case Study 1: A European fragrance producer boosted rose oil yields by 40% using our short-path Glass Wiped Film Distillation unit, achieving 2x ROI in 8 months.

Case Study 2: A US biodiesel plant reduced OPEX to $0.03/L by integrating our high-viscosity models with pre-heaters.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do you prevent thermal degradation in heat-sensitive oils?

Our wiped film mechanism creates ultra-thin material layers (<1mm), reducing heat exposure time by 70% compared to batch distillation.

Can systems handle pilot-to-production scaling?

Yes! Our modular designs allow seamless transition from 5L/hr lab units to 2000L/hr industrial configurations with data continuity.

What certifications support global distribution?

All systems meet CE, ASME, and ATEX standards. Optional GOST, CCC, and IECEx certifications available for target markets.

Do you provide cleaning validation templates?

Yes – we supply FDA/EMA-compliant SIP/CIP protocols and 3D CAD models for facility integration planning.

Contact Us

Ready to Optimize Your Glass Wiped Film Distillation Process?

Email info@welloneupe.com