Wiped Film Molecular Distillation

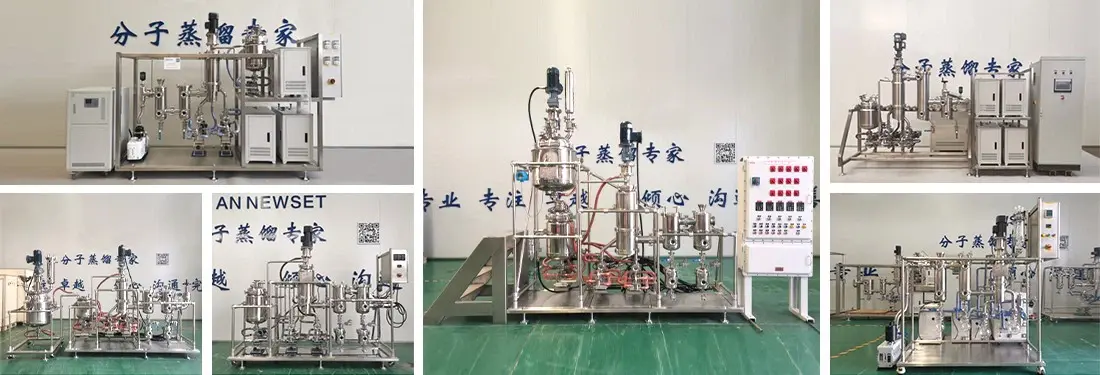

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Motor brand: SEW UL listed;

- Product Description

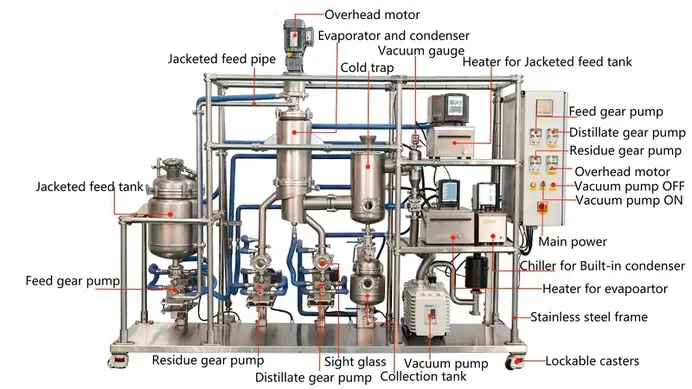

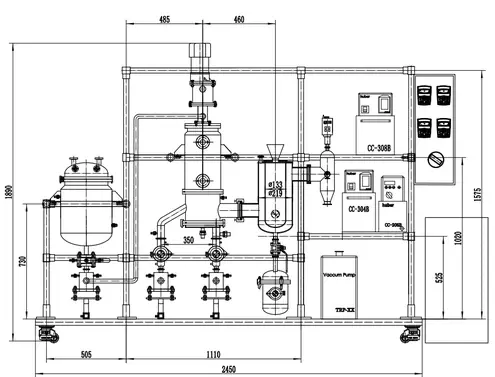

Wiped Film Molecular Distillation Description

The Wiped Film Molecular Distillation produced by the Well One are connected in series, and through continuous multi-stage distillation, the separation of multi-component complex mixtures can be achieved. Multiple experimental demonstrations are required before selection, and simple assembly is not allowed. The Well One team has over ten years of experience in selection and use, carefully recommending each device solution to customers, and assisting them in optimizing the use process of each device to the best.

Workflow Principles

The Wiped Film Molecular Distillation is a new type of high-efficiency evaporator that uses a rotating scraper to force the formation of a film for heat exchange based on the boiling point difference of each component in the mixture, and quickly separates heat through the heating surface under vacuum conditions. The material is added to the evaporator from above the heating zone; The material is distributed to the heating surface of the evaporator through a liquid distributor, and then the rotating scraper system continuously and evenly distributes the material on the heating surface, pushing it downward in a spiral shape. During this process, the light components are evaporated to form a steam flow that rises, passes through a vapor liquid separator, and then transferred to an external condenser for condensation and collection; The reconstituted component is discharged from the bottom of the evaporator.

Products Parameter

| Model | WMD-15 | WMD-30 | WMD-50 |

| Feeding Tank B01 | 15L Jacketed tank | 30L Jacketed tank | 50L Jacketed tank |

| Feed gear pump P01 | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| Evaporator E01 | a.0.15m Evaporation area b.0.3㎡ Inter cooler area c.125mm inner diameter d.Magnetic sealing e.Wiper or Roller | a.0.3㎡ Evaporation area b.0.75m Inter cooler area c.210mm inner diameter d.Magnetic sealing e.Wiper or Roller | a.0.5㎡ Evaporation area b.1.2m Inter cooler area c.260mm inner diameter d.Magnetic sealing e.Wiper or Roller |

| Discharge gear pump P02(Residue) | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| Discharge gear pump P03(Distillate) | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| All material pipelines | Jacketed insulation | Jacketed insulation | Jacketed insulation |

| Materials | SS316L | SS316L | SS316L |

| Heater HEO1 (Main Evaporator) | 1.RT-300℃ 2.Heater power 5.5kw 3.Circulation 35L/min | 1.RT-300C 2.Heater power 10kw 3.Circulation 35L/min | 1.RT-300℃ 2.Heater power 15kw 3.Circulation 50L/min |

| Heater HE02 (Material insulation) | 1.RT-200℃ 2.Heater power 5kw 3.Circulation 25L/min | 1.RT-200℃ 2.Heater power 5kw 3.Circulation 35L/min | 1.RT-200℃ 2.Heater power 10kw 3.Circulation 50L/min |

| Heater & Chiller RE01 (Internal condenser) | 1.-20℃-200℃ 2.Heater power 3kw 3.Cooler power 3kw 4.Circulation 25L/min | 1.-20℃-200℃ 2.Heater power 4.5kw 3.Cooler power 7.5kw 4.Circulation 25L/min | 1.-20C-200℃ 2.Heater power 6kw 3.Cooler power 11kw 4.Circulation 35L/min |

| Chiller RE02 (External condenser) | 1.-80C-RT 2.-40℃ power 1.1kw, -80℃ power 450w, 3.Circulation 25L/min | 1.-80C-RT 2.-40℃ power 2kw, -80℃ power 650w, 3.Circulation 25L/min | 1.-80C-RT 2.-40℃ power 4.1kw, -80℃ power 1.2kw, 3.Circulation 25L/min |

| Vacuum Pump VP01+VP02 | Vane Vacuum Pump: TRP-48(16L/S) Turbo Pump: TYFB-600(600L/S) | Vane Vacuum Pump: TRP-60(21L/S) Turbo Pump: TYFB-600(600L/S) | Vane Vacuum Pump: TRP-90(30L/S) Turbo Pump: TYFB-1200(1200L/S) |

Products Application

Wiped Film Molecular Distillation was used to purify several aromatic oils such as litsea cubeba oil, ginger camphor oil, and patchouli oil. Molecular distillation technology is an effective method for purifying essential oils, which can concentrate a major component in aromatic oils, remove odors and colored impurities, and improve their purity. Due to the fact that this process is carried out under high vacuum and low temperature, the heating time of the material is extremely short, ensuring the quality of the essential oil, especially for aromatic oils with high boiling points and heat sensitive components, demonstrating its superiority.

Products Details

1.The utilization of KingLai brand vacuum ball valves in the molecular distillation system improves the vacuum degree. These valves are specifically designed to enhance the vacuum performance of the system, ensuring optimal operation and efficiency.

2.The system incorporates high-quality motors from the SEW brand. These motors meet the required standards and comply with UL listing, ensuring their safety and reliability. By using these motors, the system guarantees the use of top-notch electrical appliances that adhere to industry regulations.

3.The Wiper or Roller components in the system are made from imported materials such as PTFE or graphite. These materials are known for their exceptional properties, including high chemical resistance and low friction coefficient. By using these materials, the system guarantees the durability and effectiveness of the Wiper or Roller in carrying out its functions efficiently.

4.The system adopts magnetic sealing as its sealing method. This choice improves the vacuum performance of the entire system by providing a reliable and effective seal. Magnetic sealing eliminates the issues associated with traditional dynamic seals, such as leakage and wear over time. By incorporating magnetic sealing, the system enhances its vacuum integrity, reducing the risks of contamination and vacuum loss.

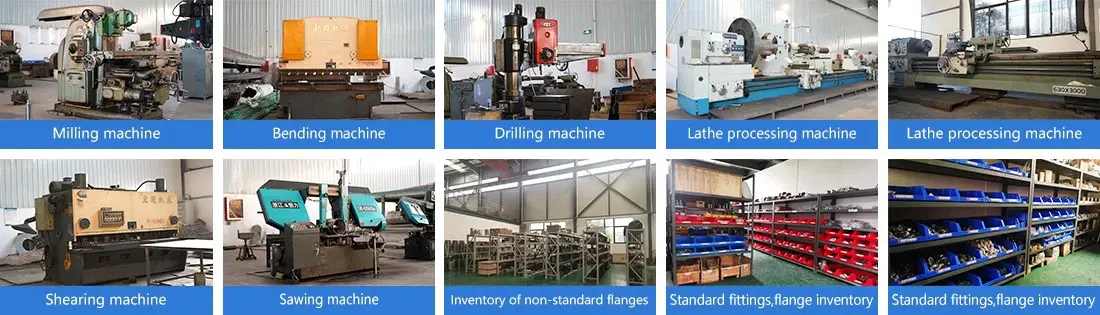

Our Factory

The company has a professional R&D and design team, strong technical support, professional production team, good after-sales service, flexible customization solutions, and can meet various standard and non-standard equipment procurement needs of customers.The company has an independent research and development laboratory, which can provide customers with comprehensive services such as feasibility research, process development, laboratory testing, and pilot testing. According to the experimental results, the company ensured the production capacity and product quality of the customer's production equipment.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

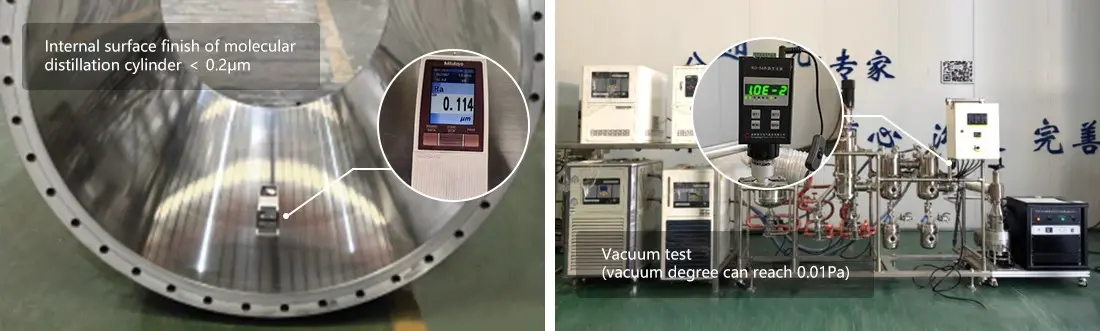

7.Surface finish and vacuum degree:

Products Qualification

1.The Well One has successfully obtained ISO quality management system certification, demonstrating its commitment to quality and excellence in its products and services. This certification is an internationally recognized standard that ensures the development, production, and supply of high-quality products and services.

2.The Well One has laboratories that meet UL certification, guaranteeing that its products adhere to industry standards for safety, quality, and performance. UL certification is a widely recognized safety certification mark that demonstrates compliance with stringent safety regulations, ensuring that Well One's products meet the necessary safety standards.

3.The Well One has over 30 product patents, demonstrating its dedication to innovation and development in its field. These patents serve as a testament to Well One's commitment to providing customers with cutting-edge products and services that solve their needs and challenges.

4.The Well One has UL certified products, ensuring their compliance with national and international safety and quality standards. UL certification serves as a guarantee to customers that Well One's products have undergone rigorous testing and have met specific safety and quality criteria. This certification underscores Well One's commitment to delivering safe and reliable products that meet customer requirements

Package

Contact Us

Request Technical Dossier & Bulk Pricing For Wiped Film Molecular Distillation → info@welloneupe.com