Short Path Wiped Film Distillation

2) Provide complex product separation and purification process packages.

3) Individual temperature control at all levels.

4) Continuous 24-hour production without shutdown.

5) Safety and environmental protection design in line with industrial production.

6) Structural design for easy operation and control.

- Product Description

Short Path Wiped Film Distillation Description

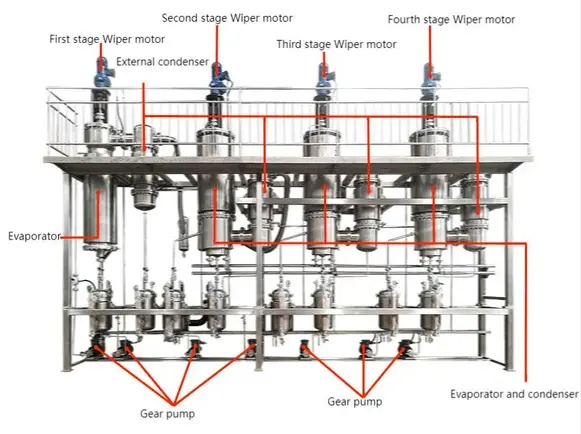

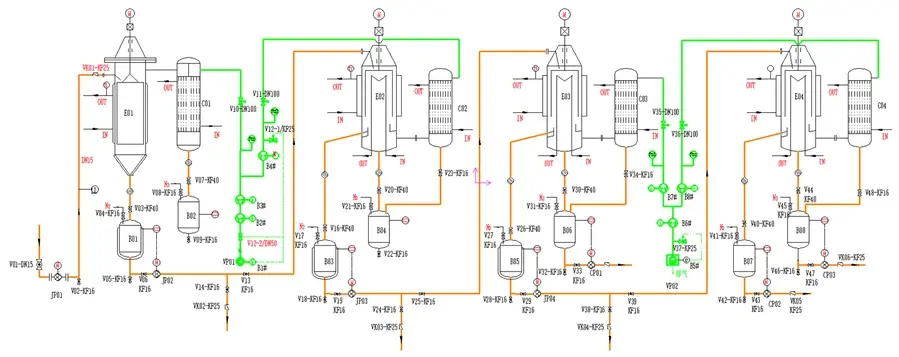

The multi-stage separation and purification system designed by Well One includes a first stage thin film evaporation device and a third stage Short Path Wiped Film Distillation device. The first stage thin film evaporation device removes low boiling solvent from the material, and the third stage molecular distillation device distills different components or enriches a certain product by setting different heating temperatures.

Workflow Principles

The raw material undergoes a thin film evaporation system to remove low boiling substances such as solvents and moisture, resulting in a content of less than 500ppm; Then enter the subsequent three stage Short Path Wiped Film Distillation device, with different heating temperatures set for each stage. Molecular distillation is divided into four distillation segments based on the average free path differences of each component in the material. In this way, a few monomers in complex mixtures can be separated or enriched to a higher content through multi-level linkage.

Well One provides a complete host system, which is equipped with 4 independent heating cycle systems by users or Wellone to heat the 4 evaporators; Supporting 2 sets or 4 sets of vacuum systems to maintain low pressure in the distillation system; Supporting multiple sets of cooling units with different temperatures, cooling and recycling the separated products.

Products Parameter

Model | WMD-200-4 |

Feeding Tank | 200L Jacketed tank,Top with 2 sight glasses, bottom with insulated ball valve |

Feed gear pump | 20L~100L/H , High precision gear pump,750W variable frequency speed regulation |

Evaporator area | 2㎡ |

Internal cooling area | 8㎡ |

Evaporator diameter | 500mm |

Sealing method | Magnetic sealing |

Scraper form | Wiper or Roller |

Discharge gear pump(Residue) | 20L~100L/H , High precision gear pump,750W variable frequency speed regulation |

Discharge gear pump(Distillate) | 20L~100L/H , High precision gear pump,750W variable frequency speed regulation |

All material pipelines | Jacketed insulation |

Materials | SS316L |

Heater(Main Evaporator) | RT-300℃/ Heater power 38kw/ Circulation 110L/min |

Heater(Material insulation) | RT-200℃/ Heater power 10kw/ Circulation 50L/min |

Heater & Chiller(Inter condenser) | -20℃-200℃/ Heater power 15kw/ Cooler power 30kw/ Circulation 70L/min |

Chiller(External condenser) | -80℃-RT/ -40℃ power 4.1kw/ -80℃ power 1.2kw/ Circulation 35L/min |

Vacuum Pump VP01+VP02 | Vane Vacuum Pump:TRP-90(30L/S)/ Roots Pump:ZJ300 (300L/S) |

Products Application

In the field of Health products: multi-stage molecular distillation equipment has been applied for the purification of natural VE, the extraction of solanesol, the refinement of nerve acids, the removal of plasticizers from natural oils, oleic acid and other harmful substances.

In the field of Petrochemical industry: preparation of high-temperature heat transfer oil, special lubricating oil, refinement of Fischer Tropsum wax, purification of petroleum derivatives, and purification and refinement of new fuels.

In the field of New materials field: refining of epoxy resin, refining of packaging adhesive, refining of film materials, synthesis of lactide, and preparation of waterproof and antifouling coatings.

Products Details

A. Equipped with an operating platform for easy operation and maintenance;

B. There are sampling ports between each level to detect material content;

C. There is a pressure isolation device between each level to maintain independent vacuum at each level;

D. High precision gear pump, precise delivery and measurement under high pressure difference;

E. The electrical appliances comply with explosion-proof environmental applications and are safe and reliable.

F. The operating components use magnetic couplings to transform dynamic seals into static seals, reducing leakage rates.

G. Using international vacuum standard connection method, with good airtightness and good system vacuum.

Our Factory

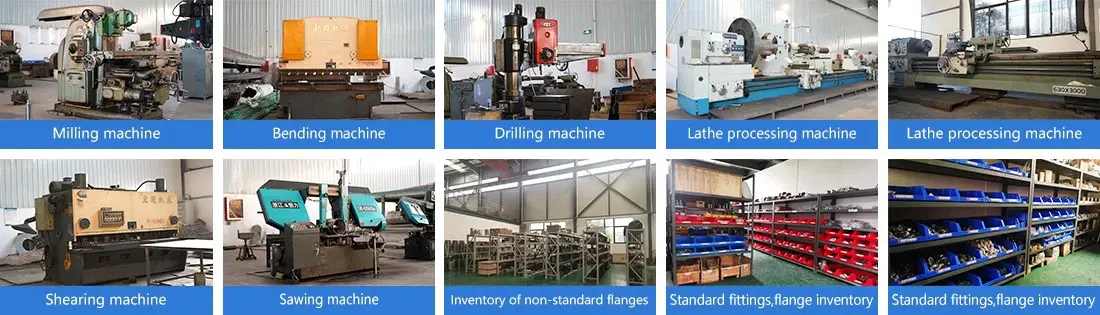

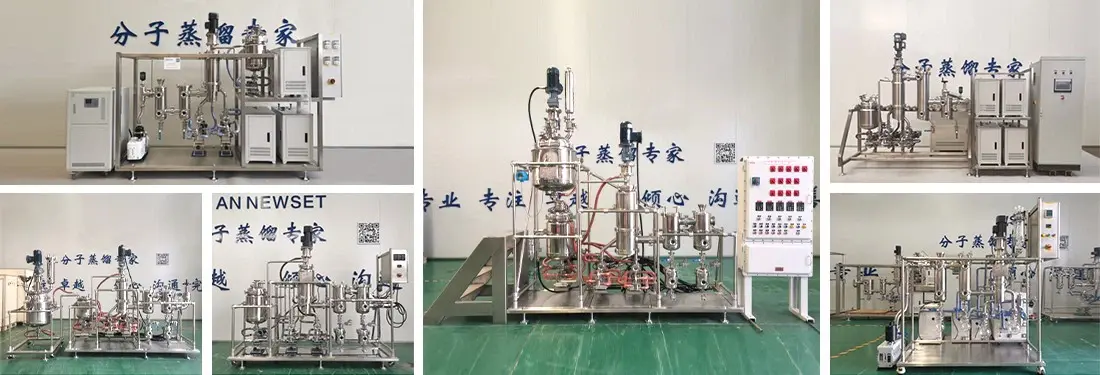

Well one company has an experienced design team, including multiple teams including process development, equipment design, automation control, and operation support, dedicated to the research and development and production of new purification and separation equipment. Our greatest advantage is the high coordination of chemical synthesis, mechanical manufacturing, and practical applications. After 17 years of experience accumulation, we have purification and separation experience in multiple fields and compounds, making us your trusted partner. Well One specializes in producing Short Path Wiped Film Distillation.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

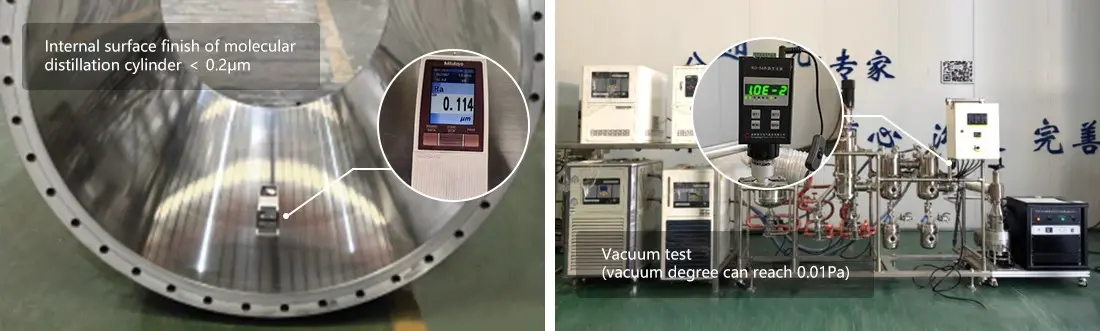

7.Surface finish and vacuum degree:

Products Qualification

Passed ISO9001 quality system certification, CE certification, and has UL testing laboratory; Each set of equipment undergoes strict testing before leaving the factory, and only products that meet quality requirements can leave the factory; All materials used have test results; Suppliers are all high-quality suppliers that have undergone strict screening, and they are randomly inspected and rated annually; Use internationally renowned brands for important components; The core technologies are protected by intellectual property and patents.

Package

1. Complies with international export wooden box packaging (non fumigation).

2. The goods can be shipped by sea, by air, small goods or spare parts will be shipped by express.

3. We can provide Delivered Duty Paid.

4.We can provide door-to-door delivery to save you time and effort, and we will bear all risks during the transportation process.

Contact Us

Request Technical Dossier & Bulk Pricing For Short Path Wiped Film Distillation → info@welloneupe.com