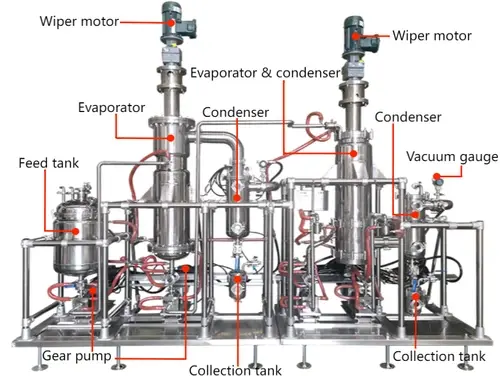

Wiped Film Distillation Equipment

2) Continuous production without stopping the machine.

3) Differentiated vacuum meets different operating conditions.

4) High temperature and corrosion resistant stainless steel material.

5) Support customization according to process requirements.

6) Electrical appliances meet UL, ATEX, IECEx, and 3C certifications.

7) 1-year warranty with 24-hour online technical support.

8) Factory directly sale help you save cost and time.

- Product Description

Wiped Film Distillation Equipment Description

The Well One Dual stage Wiped Film Distillation Equipment device, including a primary thin film evaporation device and a second molecular distillation device, is the most commonly used multi-stage series connection method in industrial production. Thin film evaporation is responsible for removing low boiling point components such as solvents and moisture from materials, and molecular distillation is responsible for separating the required high boiling point products. The evaporation area ranges from 0.1 ㎡ to 35 ㎡, and the heating temperature is less than 350 ℃. Explosion proof electrical appliances that meet the safety requirements of the place of use can be selected.

Workflow Principles

Thin film evaporator is a new type of high-efficiency evaporator that forcibly forms a film through a rotating scraper for heat exchange based on the boiling point difference of each component in the mixture, and quickly separates heat through the heating surface under vacuum conditions. The material is added to the Short Path Wiped Film Distillation evaporator from above the heating zone; The material is distributed to the heating surface of the evaporator through a liquid distributor, and then the rotating scraper system continuously and evenly distributes the material on the heating surface, pushing it downward in a spiral shape. During this process, the light components are evaporated to form a steam flow that rises, passes through a vapor liquid separator, and then transferred to an external condenser for condensation and collection; The reconstituted component is discharged from the bottom of the evaporator. Used in the first stage of a Wiped Film Distillation Equipment system, it can remove low boiling components such as solvents and moisture from the raw material. Due to the fact that the condensing unit is external and has a gas-liquid separator, it can reduce the amount of high boiling point components carried in the removed low boiling point components, making it suitable for materials containing large (greater than 5%) low boiling point components.

After removing the low boiling point components, the material enters the molecular distillation device. Due to the low boiling point components (which can be less than 500PPm), the operating vacuum of the molecular distillation system can be less than 0.1Pa, reducing the disordered molecular movement of the low boiling point components and effectively improving the purity of the products separated from the molecular distillation section.

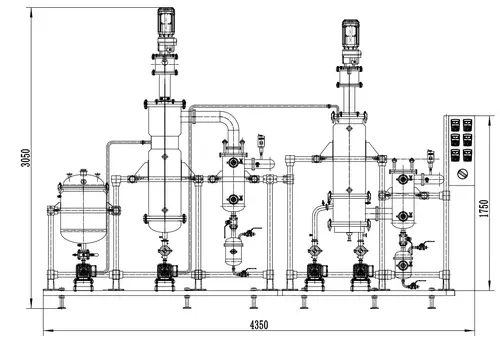

Products Parameter

Model | WMD-50-2 |

Feeding Tank | 50L Jacketed tank,Top with 2 sight glasses, bottom with insulated ball valve |

Feed gear pump | 5L~25L/H , High precision gear pump,200W variable frequency speed regulation |

Evaporator area | 0.5㎡ Evaporation area |

Internal cooling area | 1.2㎡ Inter cooler area |

Evaporator diameter | 260mm inner diameter |

Sealing method | Magnetic sealing |

Scraper form | Wiper or Roller |

Discharge gear pump(Residue) | 5L~25L/H , High precision gear pump,200W variable frequency speed regulation |

Discharge gear pump(Distillate) | 5L~25L/H , High precision gear pump,200W variable frequency speed regulation |

All material pipelines | Jacketed insulation |

Materials | SS316L |

Heater(Main Evaporator) | RT-300℃/Heater power 15kw/Circulation 50L/min |

Heater(Material insulation) | RT-200℃/Heater power 10kw/Circulation 50L/min |

Heater & Chiller(Inter condenser) | -20℃-200℃/Heater power 6kw/Cooler power 11kw |

Chiller(External condenser) | -80℃-RT/-40℃ power 4.1kw/-80℃ power 1.2kw |

Vacuum Pump VP01+VP02 | Vane Vacuum Pump:TRP-90(30L/S)/Turbo Pump:TYFB-1200(1200L/S) |

Products Application

In the field of organic synthesis: A+B=C+A, A is removed by a thin film evaporation device, and C is distilled by a molecular distillation device. The residual liquid is C+high boiling point polymers, pigments, metal ions, and other impure substances; A+B+C (solvent, not involved in the reaction)=D, C is removed by a thin film evaporation device, and D is distilled by a molecular distillation device. The residue is D+high boiling point polymers, pigments, metal ions, and other impure substances.

In the field of plant extraction: Extracts from plant flowers, leaves, roots, and stems extracted with ethanol or other solvents are concentrated in a reactor or falling film equipment, and there is still solvent residue (less than 10%). The residual solvent is removed by a thin film evaporation device, and effective plant extract components are distilled by a Molecular Distillation Equipment. The residue is the waxy component in the plant.

Refining of crystal purified materials: The materials filtered out by recrystallization using organic solvents contain organic solvents. The residual organic solvents are removed by a thin film evaporation device, and the high-purity chemicals after crystallization are distilled by a molecular distillation device to achieve decolorization and metal removal.

Products Details

1. The material flows through the pipeline with full insulation;

2. Contact the gear pump for incoming and outgoing materials;

3. There is an isolation valve between the thin film evaporation device and the molecular distillation device, and independent vacuum is maintained between each stage;

4. Electrical appliances meet explosion-proof requirements and can be placed in environments with combustible materials;

5. The pipeline is equipped with an observation window to observe the flow status of materials;

6. The thin film evaporation device and molecular distillation device are designed with independent modularity for convenient transportation.

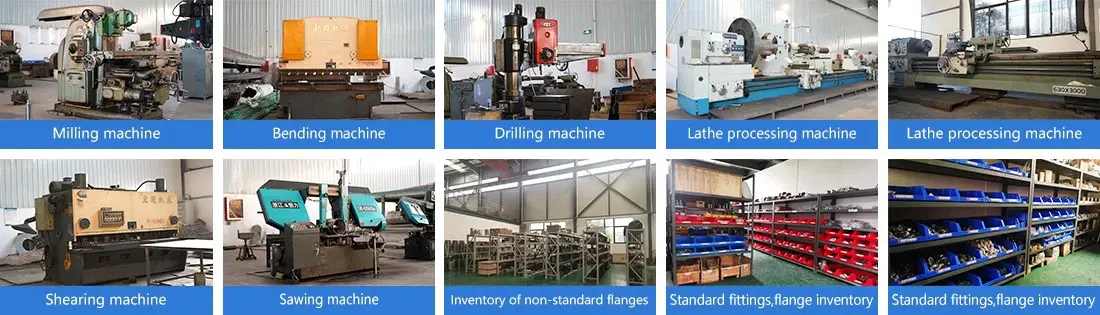

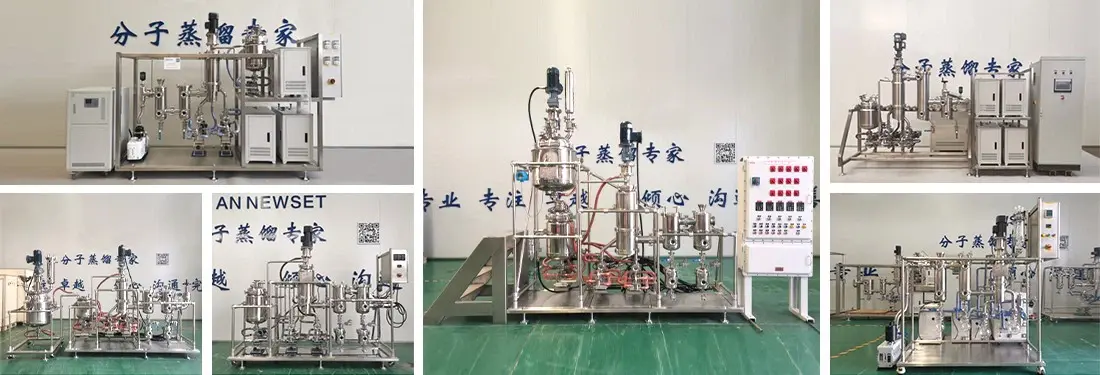

Our Factory

The core technical team of the well one is composed of professional engineers in chemical synthesis, chemical engineering and process, chemical machinery, etc. The close cooperation between chemical synthesis, bioengineering technology and mechanical manufacturing technology makes the chemical and bioengineering equipment produced by Nusat practical, compatible and progressiveness.After 17 years of effort, we focus on providing users with a series of products such as experimental Wiped Film Distillation Equipment, pilot level molecular distillation devices, industrial level Thin Film Distillation System , and multi-level continuous use systems.The user base has reached over 1000, covering more than ten countries.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

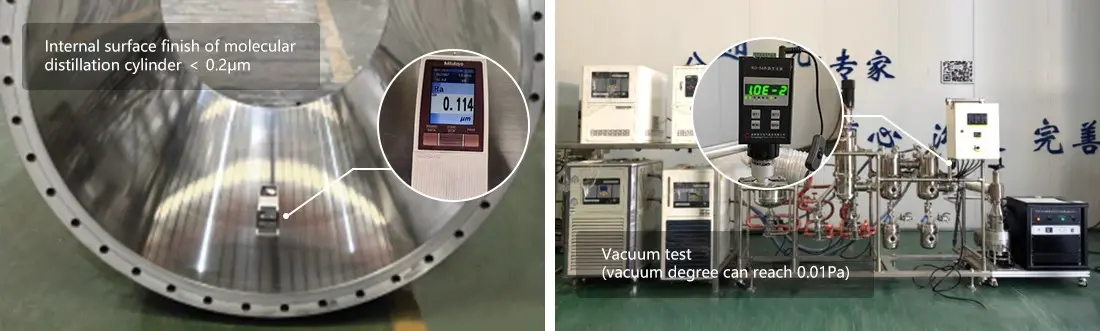

7.Surface finish and vacuum degree:

Products Qualification

1. ISO quality management system certification.

2. Laboratories that meet UL certification.

3. Over 30 product patents.

4. UL certified products.

Package

1. Complies with international export wooden box packaging (non fumigation).

2. The goods can be shipped by sea, by air, small goods or spare parts will be shipped by express.

3. We can provide Delivered Duty Paid.

4.We can provide door-to-door delivery to save you time and effort, and we will bear all risks during the transportation process.

Contact Us

Request Technical Dossier & Bulk Pricing For Wiped Film Distillation Equipment → info@welloneupe.com