Stainless Steel Molecular Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Factory supply, competitive price

- Product Description

Stainless Steel Molecular Distillation Description

The Well One Stainless Steel Molecular Distillation is utilizes molecular free paths to achieve the effect of separating samples. Instead, it relies on the difference in the average free path of molecular motion of different substances to achieve separation. Due to the fact that molecular distillation technology can solve a large number of problems that conventional distillation techniques cannot solve, this new distillation method has been widely used in the industry in recent years.

Workflow Principles

1. Install the injector (tighten the injector clockwise), the first, second, and third stage receiving bottles, and turn on the cooling water circulation button;

2. Open the scraper rotor and adjust it to the specified speed (not exceeding 400 r/min);

3. Turn on the vacuum pump after the liquid nitrogen reaches the required liquid level (not less than 1/2 of the condensate column volume);

4. When the pressure no longer decreases, adjust the vacuum pump fine tuning valve (not less than 0.5 mbar);

5. After adjusting the pressure in place, rotate the injector valve counterclockwise to adjust the injection speed;

6. During the operation of the equipment, the liquid can be added at any time through the sampler;

7. When there is about 50 ml of liquid remaining in the sampler and there is no further injection, turn off the vacuum pump, adjust the fine adjustment valve, wait for the pressure to reach 1000 mbar, wait for 10 minutes, and when the pressure is completely relieved, turn off the heater, remove the sampler, pour out the remaining sample liquid, and replace it with anhydrous ethanol;

8. Replace the first and second level receiving bottles, fill them with empty bottles, unscrew the injector, slowly inject anhydrous ethanol, and clean the equipment with residual heat;

9. To be cleaned thoroughly.

Products Parameter

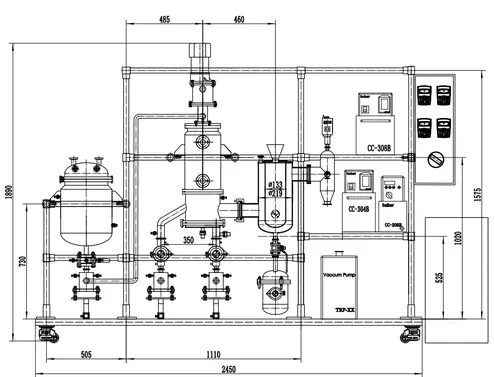

| Model | WMD-15 | WMD-30 | WMD-50 |

| Feeding Tank B01 | 15L Jacketed tank | 30L Jacketed tank | 50L Jacketed tank |

| Feed gear pump P01 | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| Evaporator E01 | a.0.15m Evaporation area b.0.3㎡ Inter cooler area c.125mm inner diameter d.Magnetic sealing e.Wiper or Roller | a.0.3㎡ Evaporation area b.0.75m Inter cooler area c.210mm inner diameter d.Magnetic sealing e.Wiper or Roller | a.0.5㎡ Evaporation area b.1.2m Inter cooler area c.260mm inner diameter d.Magnetic sealing e.Wiper or Roller |

| Discharge gear pump P02(Residue) | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| Discharge gear pump P03(Distillate) | 3L~15L/H | 5L~25L/H | 5L~25L/H |

| All material pipelines | Jacketed insulation | Jacketed insulation | Jacketed insulation |

| Materials | SS316L | SS316L | SS316L |

| Heater HEO1 (Main Evaporator) | 1.RT-300℃ 2.Heater power 5.5kw 3.Circulation 35L/min | 1.RT-300C 2.Heater power 10kw 3.Circulation 35L/min | 1.RT-300℃ 2.Heater power 15kw 3.Circulation 50L/min |

| Heater HE02 (Material insulation) | 1.RT-200℃ 2.Heater power 5kw 3.Circulation 25L/min | 1.RT-200℃ 2.Heater power 5kw 3.Circulation 35L/min | 1.RT-200℃ 2.Heater power 10kw 3.Circulation 50L/min |

| Heater & Chiller RE01 (Internal condenser) | 1.-20℃-200℃ 2.Heater power 3kw 3.Cooler power 3kw 4.Circulation 25L/min | 1.-20℃-200℃ 2.Heater power 4.5kw 3.Cooler power 7.5kw 4.Circulation 25L/min | 1.-20C-200℃ 2.Heater power 6kw 3.Cooler power 11kw 4.Circulation 35L/min |

| Chiller RE02 (External condenser) | 1.-80C-RT 2.-40℃ power 1.1kw, -80℃ power 450w, 3.Circulation 25L/min | 1.-80C-RT 2.-40℃ power 2kw, -80℃ power 650w, 3.Circulation 25L/min | 1.-80C-RT 2.-40℃ power 4.1kw, -80℃ power 1.2kw, 3.Circulation 25L/min |

| Vacuum Pump VP01+VP02 | Vane Vacuum Pump: TRP-48(16L/S) Turbo Pump: TYFB-600(600L/S) | Vane Vacuum Pump: TRP-60(21L/S) Turbo Pump: TYFB-600(600L/S) | Vane Vacuum Pump: TRP-90(30L/S) Turbo Pump: TYFB-1200(1200L/S) |

Products Application

Extraction of Lanolin and its derivatives are widely used in cosmetics.These components have relatively high molecular weight, high boiling point, and thermal sensitivity. Stainless Steel Molecular Distillation technology is used to separate each component, and physical and chemical methods are used to modify different components to obtain polyoxyethylene lanolin, acetyllanolin, lanolin acid, isopropyl ester, and wool polyoxyethylene grease with excellent performance Lanolin series products.

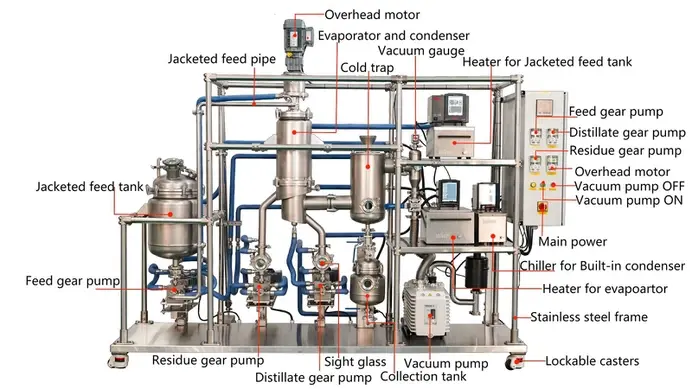

Products Details

1. Vacuum Valves – KingLai vacuum ball valves improve system vacuum degree, ensuring stable and efficient operation.

2. Motors – SEW brand motors, UL-listed, provide safe, reliable, and compliant performance.

3. Frequency Converters – ABB converters, UL-listed, deliver stable and efficient electrical control.

4. Wiper/Roller Materials – Made of imported PTFE or graphite for high chemical resistance, durability, and low friction.

5. Bearings – SKF ceramic bearings require no lubrication, avoid contamination, and ensure high wear and chemical resistance.

6. Sealing – Magnetic sealing improves vacuum integrity, prevents leakage, and reduces wear compared to traditional seals.

7. Cold Traps – Coil and liquid nitrogen cold traps enlarge condensation area, improve separation efficiency, and protect the vacuum pump.

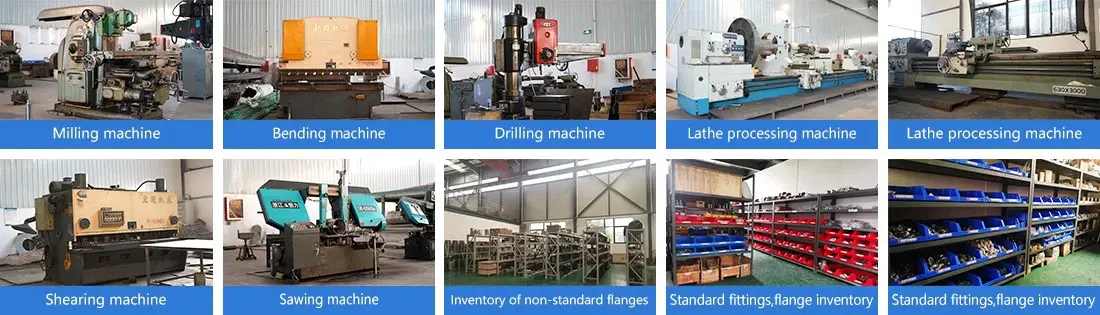

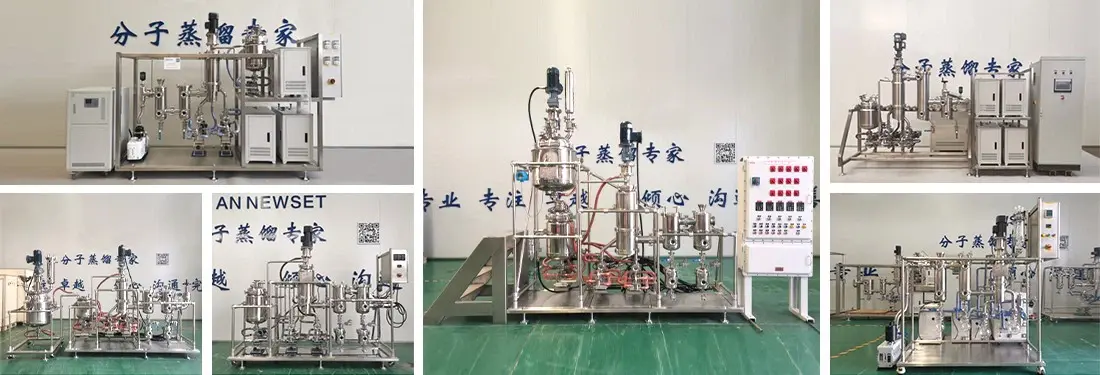

Our Factory

The company has a senior design team and a processing and manufacturing team, including process development, equipment design, 3D modeling and other designers, dedicated to the research and production of new synthesis and purification separation equipment. The company has an independent research and development laboratory, which can provide customers with comprehensive services such as feasibility research, process development, laboratory testing, and pilot testing. According to the experimental results, the company ensured the production capacity and product quality of the customer's production equipment. Well One specializes in producing Stainless Steel Molecular Distillation.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

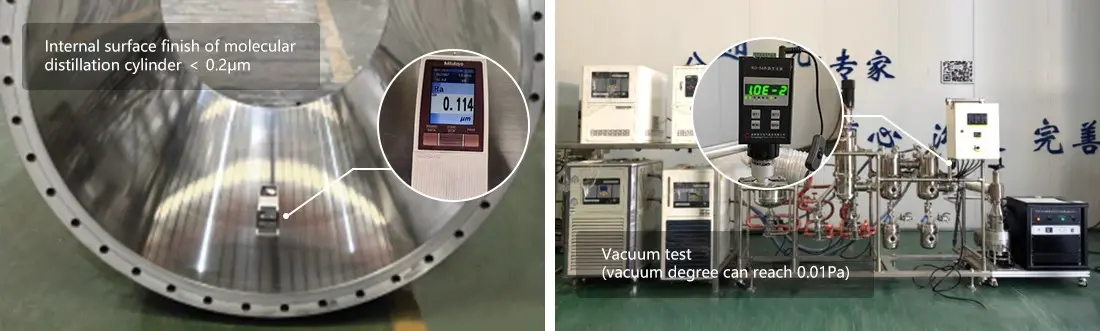

7.Surface finish and vacuum degree:

Products Qualification

Package

Contact Us

Request Technical Dossier & Bulk Pricing For Stainless Steel Molecular Distillation → info@welloneupe.com