Recycle solvents at 95%+ efficiency using Thin Film Vacuum Distillation, solar-thermal hybrids, and AI-driven purity optimization.

Thin Film Vacuum Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Stainless steel jacketed glass material feeding tank

- Product Description

High-Purity Thin Film Vacuum Distillation Systems for Heat-Sensitive & Complex Separations

Engineered for precision, compliance, and energy efficiency across pharmaceuticals, chemicals, and sustainable industries.

Transform your separation processes with our Thin Film Vacuum Distillation technology, designed to handle heat-sensitive materials like APIs, essential oils, and heavy hydrocarbons. By combining rapid heat transfer, precise vacuum control (<0.1Pa), and corrosion-resistant materials, our systems minimize thermal degradation while achieving 99%+ purity. Whether you’re scaling solvent recovery or preserving volatile compounds, our solutions deliver unmatched efficiency.

How Our Thin Film Vacuum Distillation Technology Works?

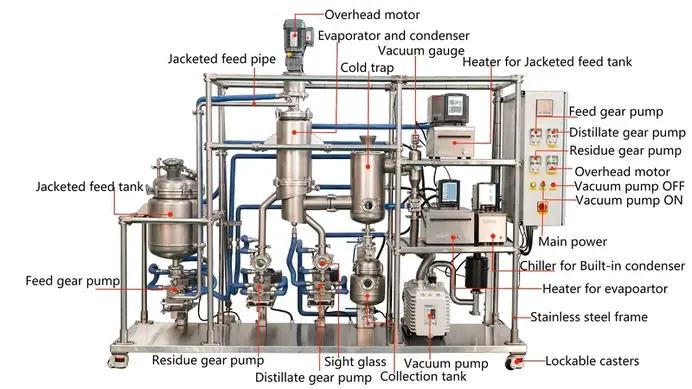

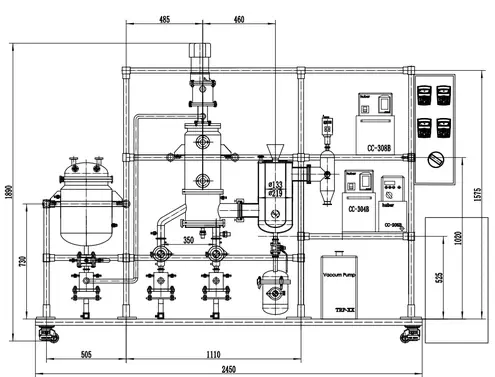

Our systems use short-path evaporation to create a thin, uniform material film on heated surfaces. This minimizes exposure to high temperatures, preventing degradation. Key features include:

- Vacuum Optimization: Operates at 0.1Pa–10 mbar for lower boiling points.

- Material Flexibility: Compatible with SS316L, Hastelloy, and glass-lined surfaces.

- ABB Control Systems: Ensure ±1°C temperature accuracy and real-time pressure adjustments.

Ideal for viscous or heat-sensitive substances, the process reduces energy use by 30–50% compared to traditional methods.

Industry-Specific Solutions

Pharmaceuticals

Meet GMP/ISO 13485 standards with electropolished surfaces, CIP/SIP compatibility, and audit-ready documentation. Achieve ≤0.1% impurities in APIs with minimal batch time.

Petrochemicals

Handle heavy hydrocarbons (up to 300°C) using anti-coking coatings and automated slag discharge. Boost yields by 22% while reducing fouling.

Essential Oils

Preserve terpenes and flavonoids with low-temperature operation (<50°C) and food-grade materials.

Environmental Tech

Technical Advantages

| Feature | Specification |

|---|---|

| Evaporation Area | 0.1–40 m² models |

| Throughput | 5–5,000 L/hour |

| Certifications | CE, ISO 9001, ASME, FDA 21 CFR Part 11 |

| Materials | SS316, Hastelloy, Titanium |

| Vacuum Range | ≤0.1Pa |

Why Choose Us?

- 30% Lower Energy Costs: Heat recovery systems slash operational expenses.

- 1-Year Warranty: Includes 24/7 remote monitoring and spare parts support.

- Customizable Designs: Modular setups scale from pilot batches to 10,000 L/day.

Real-World Results

Case Study: Petrochemical Refinery

A Middle East client increased heavy wax yield by 22% using our ATEX-certified system with anti-coking coatings. ROI achieved in 14 months.

Case Study: Pharma Manufacturer

Reduced API processing time by 35% while meeting FDA data integrity requirements.

Trusted by Global Leaders

ACHEMA Innovation Award Winner | ISO 14001 Certified

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does thin film distillation prevent thermal degradation?

By reducing material residence time to seconds and maintaining precise low-temperature control.

Can this system handle viscous petrochemicals?

Yes. Our high-vacuum evaporators with automated slag discharge minimize clogging.

What post-purchase support is included?

We offer 24/7 troubleshooting, operator training, and a 48-hour spare parts guarantee.

Contact Us

Ready to Optimize Your Thin Film Vacuum Distillation Process?

Questions? Contact our engineers at info@welloneupe.com.