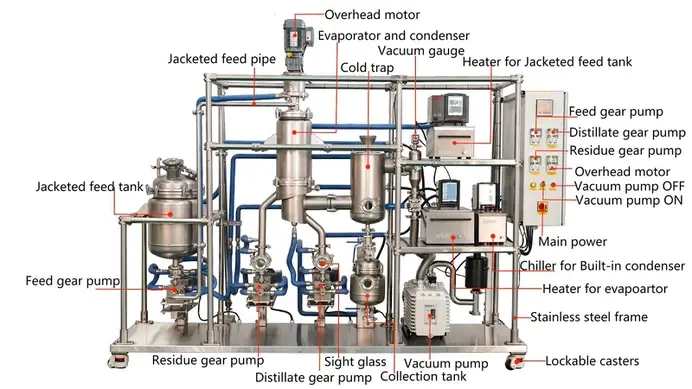

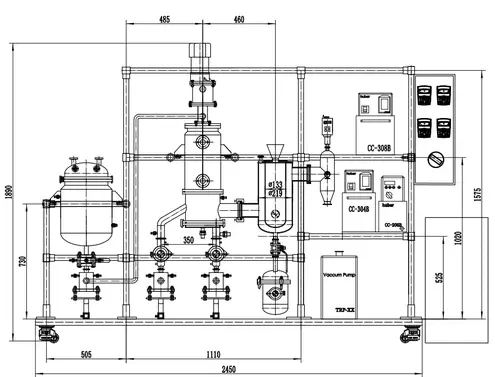

Thin Film Distillation Equipment

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) New design glass evaporator to observe whole distillation process clearly

- Product Description

High-Efficiency Thin Film Distillation Equipment for Precision Separation

Achieve ultra-pure separation with minimal energy consumption using our advanced Thin Film Distillation Equipment. Designed for industries requiring precise thermal separation of heat-sensitive compounds, our systems reduce thermal degradation by 40% while ensuring ≤0.5% residue in final outputs. Whether you’re refining essential oils, recovering solvents, or processing petrochemicals, this equipment delivers unmatched efficiency.

Tailored Solutions for Your Industry

Chemical & Petrochemical

- Separate high-boiling-point hydrocarbons (C9–C11) with ≤0.5% residue using corrosion-resistant Hastelloy construction.

- Handle aggressive chemicals at temperatures up to 300°C.

Pharmaceuticals & Biotechnology

- GMP-compliant systems with <0.1% residual solvents for API purification.

- Integrated CIP/SIP capabilities and FDA-approved 316L stainless steel.

Food & Beverage

- Preserve volatile aromas in essential oils with short residence time (<10 seconds).

- EHEDG-certified designs for odor-free, food-grade processing.

Environmental Management

- Recover 99.9% pure solvents from hazardous waste streams.

- Explosion-proof models compliant with ISO 14001 and REACH.

Why Choose Our Thin Film Distillation Equipment?

✅ Patented Thin Film Technology: 0.1mm film thickness for rapid, uniform heat transfer.

✅ Global Certifications: CE, ISO 9001, ASME, and GMP.

✅ Material Flexibility: Choose from 316 stainless steel, titanium, or glass-lined surfaces.

✅ Energy Savings: 30% lower energy use via integrated heat recovery.

✅ 1-Year Warranty: Full coverage for parts and labor.

Key Features at a Glance

| Specification | Detail |

|---|---|

| Vacuum Range | 0.001–500 mbar |

| Throughput | 1–8,000 kg/h |

| Heating Surface | 0.05–300 m² |

| Material Options | 316L SS, Hastelloy, Glass-Lined |

| Control System | ABB Automation with Real-Time Monitoring |

See It in Action: Glass Evaporator Design

Our new observation window lets you monitor the entire distillation process visually—ideal for R&D and quality control.

Trusted Worldwide

From Fortune 500 petrochemical plants to boutique essential oil producers, our Thin Film Distillation Equipment powers precision across 45 countries.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does this equipment handle heat-sensitive materials?

The thin-film design reduces contact time to seconds, minimizing thermal degradation even at high temperatures.

What materials are used for corrosive chemicals?

We offer Hastelloy C-276 and titanium builds resistant to HCl, H2SO4, and other aggressive media.

Can it integrate with existing GMP systems?

Yes! Our pharma-grade models include validation support and audit-ready data logging.

How does it preserve aromas in essential oils?

A low-pressure vacuum (<5 mbar) and rapid evaporation retain volatile compounds effectively.

What energy-saving features are included?

Heat recovery coils and variable-speed drives cut energy use by up to 30%.

Contact Us

Ready to Optimize Your Thin Film Distillation Equipment Process?

📧 Contact Us Today: info@welloneupe.com