A Texas plant upgraded to our Short Path Thin Film Distillation Hastelloy C-22 units, enabling 24/7 processing of chlorinated solvents with zero corrosion over 18 months.

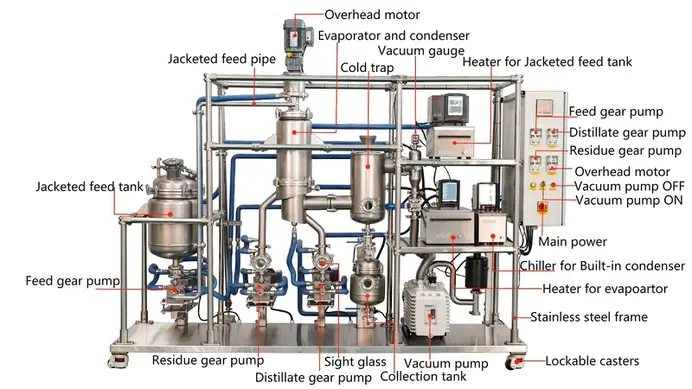

Short Path Thin Film Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Manufacturer best price

- Product Description

Precision Short Path Thin Film Distillation Systems for High-Purity Separation

When processing heat-sensitive compounds such as pharmaceuticals, essential oils, or specialty chemicals, Short Path Thin Film Distillation (SPTFD) provides unmatched purity while carefully preserving molecular integrity. Our advanced systems integrate ultra-low operating pressures, reaching down to 0.1Pa, with precise temperature control, allowing the effective isolation of volatile components with less than 1% thermal degradation. Designed to accommodate both small-scale laboratory experiments and full-scale industrial production, our modular systems are highly adaptable, offering throughput ranges from 1L/h R&D units to over 500L/h industrial reactors, ensuring flexibility, efficiency, and consistent high-quality results across diverse applications.

Why Industries Trust Our SPTFD Technology

1. Preserve Delicate Compounds

- Heat-sensitive materials: Maintain <100°C evaporation temperatures for APIs, terpenes, and antioxidants.

- High-vacuum efficiency: Achieve 99.5%+ purity by minimizing boiling points through reduced pressure.

2. Tailored for Your Industry

- Pharma/Nutraceuticals: GMP-compliant systems with CIP/SIP for cross-contamination-free API isolation.

- Essential Oils: Glass-lined evaporators prevent metallic leaching, preserving aroma profiles.

- Recycling: Corrosion-resistant Hastelloy wipers handle abrasive pyrolysis oils and solvents.

3. Future-Proof Scalability

- Upgrade lab prototypes to production without re-engineering (1L/h → 500L/h).

- Add automated PLC controls or multi-stage configurations post-installation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Materials | 316L SS, Hastelloy, Borosilicate Glass |

| Vacuum Range | 0.1Pa – 5kPa |

| Throughput | 1–500L/h |

| Temperature Control | ±0.5°C (ABB PLC Systems) |

| Certifications | CE, ISO 9001/14001, ASME, GMP |

Solving Critical Industry Challenges

Case 1: CBD Oil Distillation

A European producer reduced winterization steps by 60% using our 3-stage SPTFD system, achieving 99.2% THC-free CBD isolate with full terpene recovery.

Case 2: Petrochemical Recycling

SPTFD vs. Traditional Methods

| Factor | SPTFD | Rotary Evaporation |

|---|---|---|

| Residence Time | 10–30 seconds | 60+ minutes |

| Max Purity | 99.9% | 85–92% |

| Energy Use/Liter | 0.8kW | 2.5kW |

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does SPTFD protect heat-sensitive compounds?

By maintaining vacuum levels below 1Pa, boiling points drop by 150–200°C versus ambient pressure, preventing thermal breakdown.

Can I validate these systems for FDA submissions?

Yes—we provide IQ/OQ/PQ documentation packs and 21 CFR Part 11-compliant data logging.

What maintenance is required?

Annual seal inspections and biweekly wiper adjustments ensure peak performance. Most clients achieve 5+ years between major overhauls.

Contact Us

Optimize Your Short Path Thin Film Distillation Purification Process Today:

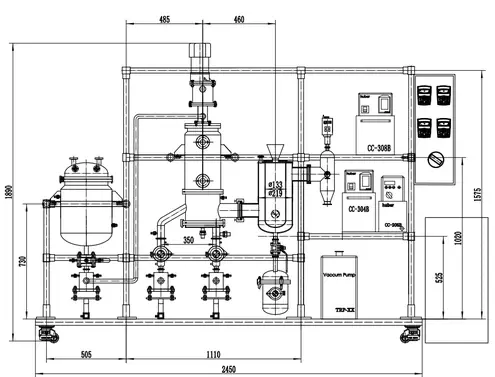

Email info@welloneupe.com for a free distillation efficiency audit or to request CE-certified CAD drawings.