Molecular Distillation Equipment

2) We have over 50 application cases.

3) 17 years in the molecular distillation field.

4) Supply Single stage, Dual stage, Three stage.

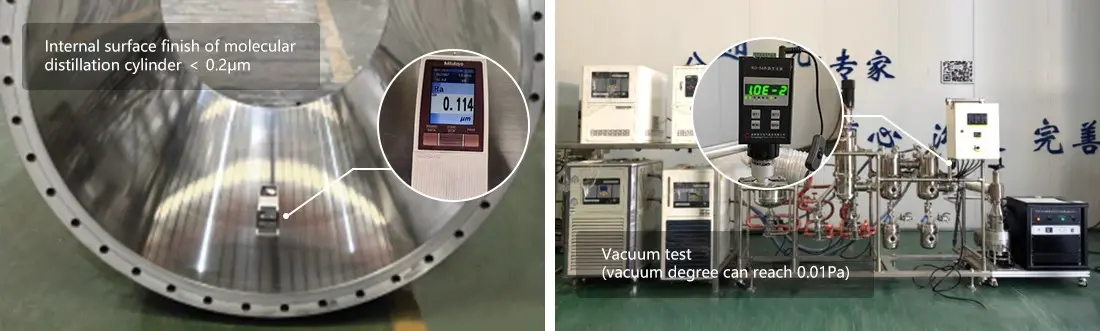

5) High vacuum degree: 0.01Pa.

6) Control system: ABB or SEW.

7) Material:316L stainless steel.

8) OEM & ODM support.

9) Warranty:12 months.

- Product Description

Molecular Distillation Equipment Description

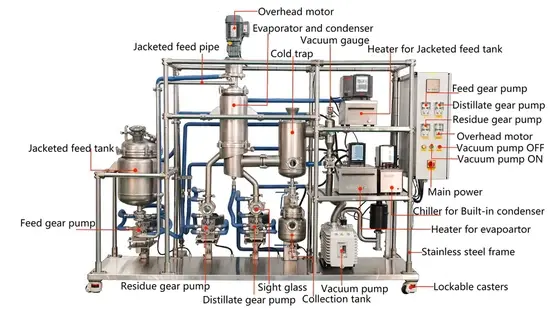

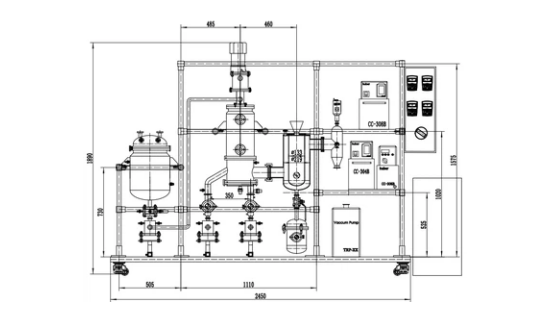

The Well One Molecular Distillation Equipment is a new substance separation technology that can separate liquid-liquid mixtures under any temperature lower than the boiling point is an important advantage. This helps to minimize any thermal degradation or damage to the target product, which can be particularly useful when working with heat-sensitive or easily oxidized substances.The standard wiped film distillation unit host produced by Well One includes raw material tanks, feed pumps, evaporators, light discharge pumps, heavy discharge pumps, cold traps, brackets, and controllers.And Well One holds over 30 patents, all electrical appliances comply with international standard certifications (UL listed, CE certified, CSA certified, GMP standard, ATEX certified).The following is a detailed introduction to our WMD-30 (0.3 ㎡) molecular distillation:

Workflow Principles

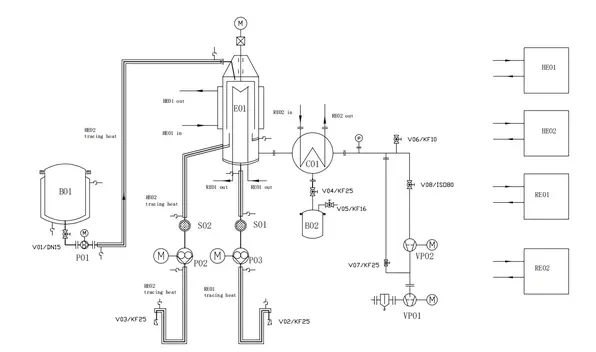

As shown in the figure, the feed pump (P01) continuously transports the materials from the raw material storage tank (B01) to the top of the Molecular Distillation Equipment evaporator (E01), and evenly distributes the materials on the heating surface through the distributor; After the mixed liquid is heated, small molecule materials overflow from the surface and are captured and collected by the internal condenser located in the middle of the evaporator, and discharged through the discharge pump (P03); The residual macromolecular liquid is discharged through the discharge pump (P02); The trace small molecules that were not captured by the intermediate condenser are collected again through the cold trap C01 to prevent pollution to the vacuum pump (VP01) or to the atmosphere.

Products Parameter

Model | WMD-30 |

Material tank | 30L Jacketed tank,Top with 2 sight glasses, bottom with insulated ball valve |

Feed gear pump | 5L~25L/H , High precision gear pump,200W variable frequency speed regulation |

Evaporator area | 0.3㎡ Evaporation area |

built-in condenser area | 0.75㎡ Inter cooler area |

Evaporator diameter | 210mm inner diameter |

Max Speed (rpm) | 350 |

Sealing method | Magnetic sealing |

Scraper blade | Wiper or Roller |

Discharge gear pump | 5L~25L/H ,200W variable frequency speed regulation |

All material pipelines | Jacketed insulation |

Materials | SS316L |

Vacuum Level (mbar) | Low to 0.001 mbar |

Heater for Main Evaporator | UC-200-5 RT-300℃/Heater power 10kw/Circulation 35L/min |

Heater for Material insulation | UC-200-5 RT-200℃/Heater power 5kw/Circulation 35L/min |

Heater & Chiller for Inter condenser | GDX-30/30+200 -20℃-200℃/Heater power 4.5kw/Cooler power 7.5kw |

Chiller for External condenser | DSLB-20/80 -80℃-RT/-40℃ power 2kw/-80℃ power 0.65kw |

Vacuum system | Vane Vacuum Pump:TRP-60(21L/S)/Turbo Pump:TYFB-600(600L/S) |

Equipment Height mm | 2650 |

Products Application

Pharmaceutical Industry:(Synthetic pharmaceutical intermediates, pharmaceutical monomers, plant extract pharmaceutical refining, fermentation pharmaceutical intermediate refining.)

New Materials Industry:(Epoxy resin, liquid crystal material, OLED material, potassium battery additive, P-type flexible material, adhesive, waterproof material, plasticizer.)

Food Industry:(MCT oil, walnut oil, seabuckthorn seed oil, maple oil, Ganoderma lucidum seed oil, monoglyceride, VE, fish oil, carotene, etc.)

Essence Industry:(Food flavoring agents such as tobacco essence, rose essential oil, orange peel oil, cypress oil, agarwood, desorbiderin, perilla alcohol, sweet orange oil, prickly ash oil, ginger oil, etc.)

Petrochemical Industry:(Polyol Cool Lubricants, Silicone Oil, Waste Lubricant Regeneration, Polyacid Greases, Polyolefins, High Temperature Heat Transfer Oils, Aviation Lubricants.)

Products Details

1.The use of KingLai brand vacuum ball valves in the molecular distillation system can contribute to improved vacuum performance. These valves are specifically designed for vacuum applications and are known for their reliability and sealing capabilities, which help maintain a high vacuum level during the distillation process.

2.By employing high-quality motors from SEW brand, the electrical components of the system comply with UL (Underwriters Laboratories) listing. This means that the motors meet the safety standards set by UL, ensuring safe and reliable operation of the equipment.

3.The incorporation of high-quality frequency converters from ABB brand ensures that the electrical components of the system also comply with UL listing. The frequency converters, which are used for controlling the speed of the motors, meet the safety and performance requirements specified by UL.

4.The wiper or roller component of the system is made of imported PTFE (polytetrafluoroethylene) or graphite material. PTFE and graphite are known for their excellent chemical resistance and low friction properties, making them suitable for use in molecular distillation systems. These materials help ensure efficient scraping of the liquid film and minimize the risk of contamination or reaction with the processed substances.

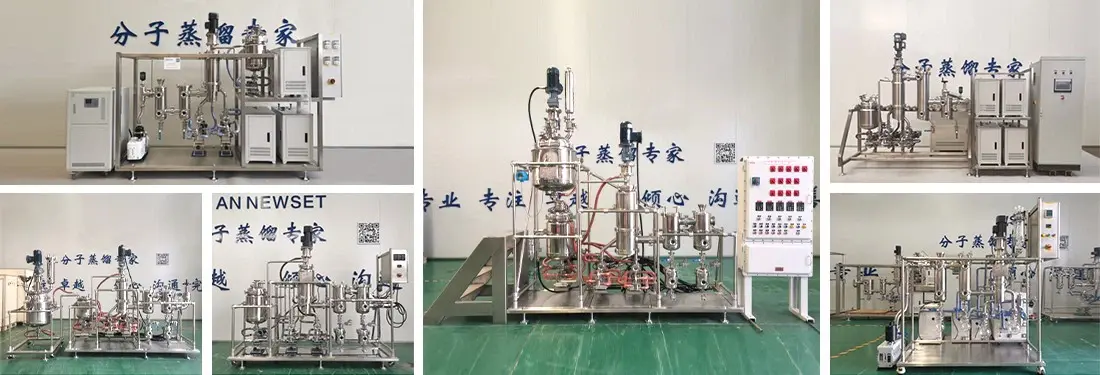

Our Factory

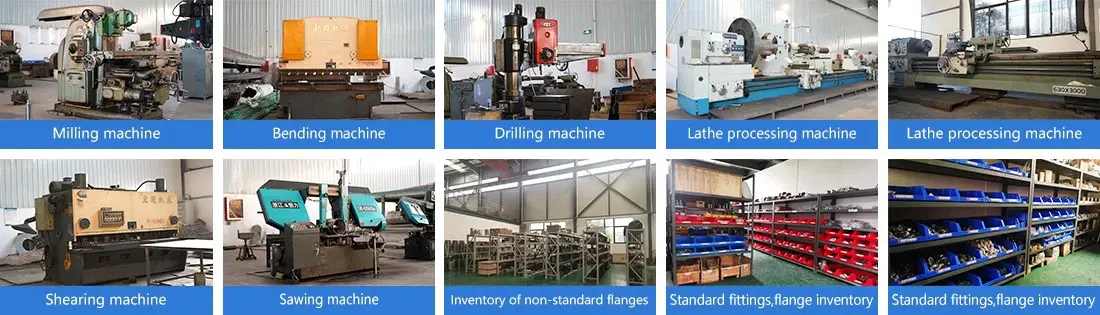

Well One is an exclusive export company authorized by Xi'an NewSet Chemical Equipment Technology Co., Ltd., established in 2006, with 17 years of production and manufacturing experience. Located in the Sanyuan Precision Equipment Industrial Park in Xi'an, Shaanxi, it has a 1500 square meter office building, a 500 square meter research and development analysis laboratory, and a 4500 square meter equipment processing and manufacturing factory. The company has a senior design team and a processing and manufacturing team, including process development, equipment design, 3D modeling and other designers, dedicated to the research and production of new synthesis and purification separation equipment. The company has an independent research and development laboratory, which can provide customers with comprehensive services such as feasibility research, process development, laboratory testing, and pilot testing. According to the experimental results, the company ensured the production capacity and product quality of the customer's production equipment. After 17 years of effort, we focus on providing users with a series of products such as lab scale Molecular Distillation Equipment, pilot sacle Thin Film Distillation System, industrial sacle Wiped Film Distillation Equipment, and multi-level continuous use Short Path Wiped Film Distillation.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

7.Surface finish and vacuum degree:

Products Qualification

1. Passed ISO quality management system certification.

2. Laboratories that meet UL certification.

3. Over 30 product patents.

4. UL certified products.

Package

1. Complies with international export wooden box packaging (non fumigation).

2. The goods can be shipped by sea, by air, small goods or spare parts will be shipped by express.

3. We can provide Delivered Duty Paid.

4.We can provide door-to-door delivery to save you time and effort, and we will bear all risks during the transportation process.

Contact Us

Request Technical Dossier & Bulk Pricing For Molecular Distillation Equipment → info@welloneupe.com