Vacuum Distillation Equipments

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Factory directly sale for fast delivery

- Product Description

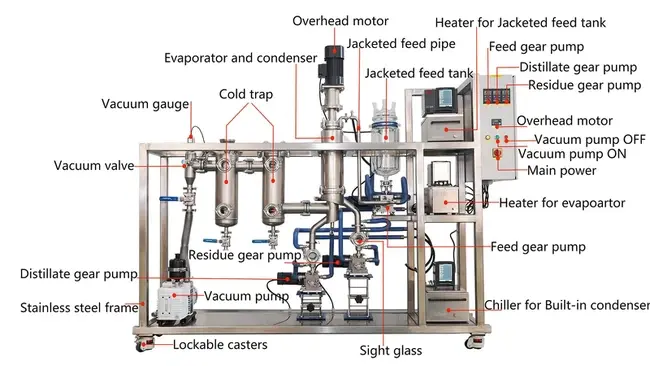

Vacuum Distillation Equipments: Precision Engineered for Industrial Excellence

When it comes to separating heat-sensitive compounds with unmatched efficiency, Vacuum Distillation Equipments stand as the backbone of modern industrial processes. At Wellone, our systems combine AI-driven optimization, corrosion-resistant alloys, and multi-stage condensation to deliver 99.8% purity outputs. Whether you’re refining crude oil, isolating pharmaceutical APIs, or extracting delicate essential oils, our vacuum distillation systems are engineered to maximize yield, minimize energy costs, and comply with global certifications like ISO 9001 and ASME.

Core Technology & Innovation

Multi-Stage Condensation & Adaptive Control

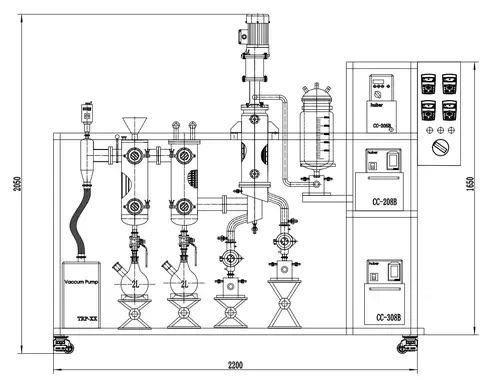

Our vacuum distillation units feature modular designs that scale from 5L pilot setups to 20kL industrial reactors. Proprietary adaptive vacuum control maintains ±0.5 mbar precision, even under fluctuating loads. Built with Hastelloy alloys or 316L stainless steel, these systems resist corrosion from acidic byproducts, sulfur-rich feedstocks, and harsh solvents.

Industry-Leading Efficiency

- AI-Driven Optimization: Predictive algorithms adjust temperature and pressure in real time, reducing energy use by 15–25%.

- Scalable Configurations: Upgrade from single-stage to triple-stage distillation without downtime.

- Cold Trap Technology: Preserve volatile aromas and terpenes with AromaGuard™ condensers.

Solutions Tailored to Your Industry

Petrochemical & Oil Refining

- High-Temperature Stability: ASME-certified trays withstand 450°C+ for crude oil fractionation.

- Sulfur Resistance: Hastelloy C-276 reactors prevent corrosion in sour gas processing.

Pharmaceuticals & Biotechnology

- GMP Compliance: Tri-clamp fittings, electropolished surfaces, and 21 CFR Part 11 data logging.

- CIP/SIP Integration: Reduce cross-contamination risks with automated cleaning cycles.

Essential Oils & Flavors

- Glass-Lined Condensers: Eliminate metal contact to preserve fragrance integrity.

- Rapid Batch Turnover: Process 200L/hr with <1% thermal degradation.

Environmental Waste Recycling

- ATEX-Certified Safety: Explosion-proof motors and VOC scrubbers for hazardous materials.

- High Throughput: Process 500–2,000 kg/day of industrial waste.

Research & Academia

- IoT-Enabled Monitoring: Track pressure, temperature, and distillate composition in real time.

- Modular Kits: Swap components for testing novel separation techniques.

Performance Metrics at a Glance

| Model | Flow Rate (L/h) | Vacuum Range (mbar) | Max Temp (°C) | Material Options |

|---|---|---|---|---|

| WD-300 | 10–50 | 0.1–500 | 200 | 316L SS, PTFE |

| WD-2000 | 200–500 | 0.5–1,000 | 350 | Hastelloy, Borosilicate |

| WD-20K | 1,000–2,000 | 1–5,000 | 450 | Titanium, Glass-Lined |

Why Choose Our Vacuum Distillation Equipments?

- 20+ Year Lifespan: Machined from ultra-durable alloys.

- Global Certifications: CE, ASME, FDA, ATEX, and EHEDG.

Real-World Success Stories

- Oil Refinery, UAE: Cut energy costs by 40% using AI-optimized vacuum towers.

- Biotech Lab, Germany: Achieved 99.5% CBD purity with GMP-compliant isolation.

- Citrus Producer, Brazil: Boosted terpene retention to 90% via cold traps.

Ready to Optimize Your Process?

Use our interactive configurator to tailor Vacuum Distillation Equipments to your capacity, industry, and automation needs.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

Q: How do your systems handle corrosive feedstocks in petrochemical plants?

A: Hastelloy reactors and PTFE coatings resist sulfur and acids, ensuring a 20+ year lifespan.

Q: Are your units compatible with FDA audits for pharma use?

A: Yes! We provide full IQ/OQ/PQ documentation and 21 CFR Part 11-compliant data logs.

Q: Can I upgrade my system’s capacity later?

A: Absolutely. Modular designs allow seamless scaling from pilot to full production.

Contact Us

Email info@welloneupe.com for Vacuum Distillation Equipments consultation. Let’s build your solution today!