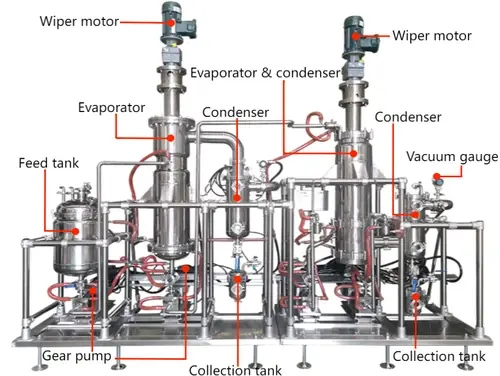

Stainless Steel Wiped Film Molecular Distillation

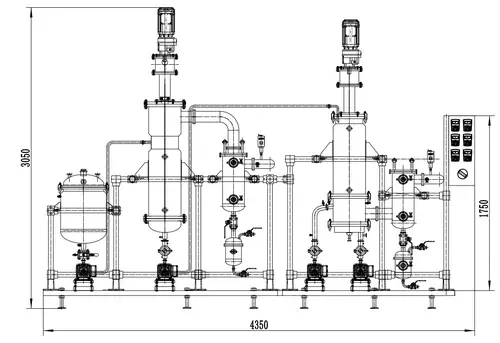

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) 24h Continuously Running

- Product Description

GMP-Certified Stainless Steel Wiped Film Molecular Distillation Systems for High-Purity Separation

Transform your separation processes with Stainless Steel Wiped Film Molecular Distillation technology, meticulously engineered for precision, durability, and regulatory compliance. Ideal for applications in pharmaceuticals, essential oils, and specialty chemicals, our advanced systems integrate robust 316L stainless steel construction with state-of-the-art wiped film design to achieve unparalleled purity levels. By protecting heat-sensitive compounds and ensuring minimal thermal degradation, these systems deliver consistent, high-quality results across a variety of production scales. From laboratory research to pilot and industrial operations, they provide reliable performance, operational efficiency, and scalable solutions tailored to your separation challenges.

Why Choose Our Molecular Distillation Systems?

Industrial-Grade Durability

- 316L stainless steel components resist corrosion from aggressive chemicals and high temperatures (50°C to 300°C).

- Vacuum levels down to 0.001 mbar enable low-temperature processing to preserve volatile compounds like terpenes or CBD isolates.

- Self-cleaning rotor scrapers maintain consistent thin-film distribution, even for materials up to 50,000 cP viscosity.

Tailored for Your Industry

- Pharma/Nutraceuticals: Achieve ≤1ppm solvent residues in API purification with CIP/SIP-ready designs.

- Essential Oils: Preserve 98%+ terpene profiles using ≤40°C evaporation zones.

- Petrochemicals: Separate high-viscosity polymers with HVOF-coated surfaces for ≤0.01% cross-contamination.

- Food & Cosmetics: Meet 3-A sanitary standards for odor-free, oxidation-resistant edible oil refinement.

Trusted by Global Leaders

Our Stainless Steel Wiped Film Molecular Distillation systems are fully certified for quality, safety, and regulatory compliance, ensuring reliable operation and consistent performance across pharmaceutical, chemical, and essential oil applications:

- GMP/FDA Compliance: Full documentation for pharmaceutical audits.

- ASME & ATEX Standards: Safe operation in explosive atmospheres.

- Energy Efficiency: 30% lower power consumption vs. traditional evaporators.

Real-World Results

- CBD Manufacturer: Boosted isolate purity from 92% to 99.5% using a GMP-validated system.

- Essential Oil Producer: Reduced lavender oil processing time by 40% with precise temperature controls.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does the product prevent thermal degradation?

Our rotating scrapers create a uniform thin film, reducing material exposure to heat by 70% compared to batch distillation.

Can I scale from lab trials to full production?

Yes! We offer modular systems from 5L pilot units to 2000L industrial-scale evaporators with identical performance parameters.

What maintenance is required?

Self-cleaning wipers and accessible disassembly points reduce downtime by 40%, with most parts replaceable in ≤2 hours.

Contact Us

Contact our Stainless Steel Wiped Film Molecular Distillation experts today to discuss your project:

📧 info@welloneupe.com