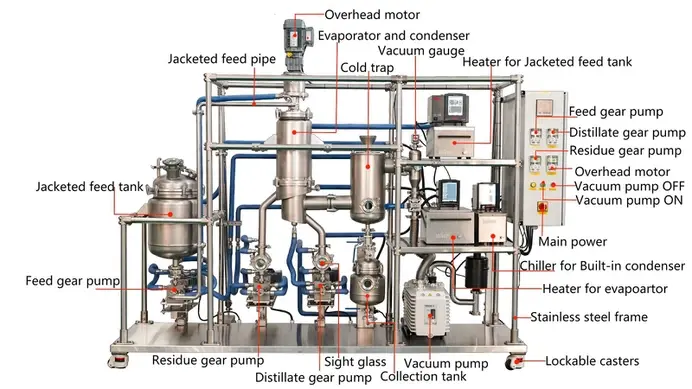

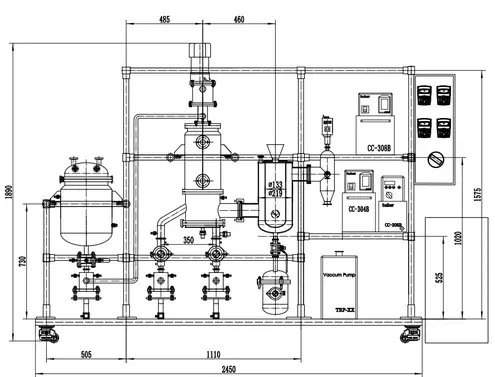

Industrial Molecular Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) essential oil, fish oil, waste oil, etc

- Product Description

High-Purity Industrial Molecular Distillation Systems for Scalable, Precision Separation

GMP/FDA-Compliant Industrial Molecular Distillation Units for APIs, Essential Oils, Chemicals & Food Ingredients. Preserve Heat-Sensitive Compounds with ≤0.01% Thermal Degradation.

Why Choose Our Industrial Molecular Distillation Systems?

The product technology is the cornerstone of high-purity separation for heat-sensitive materials. Whether you’re isolating pharmaceutical-grade compounds, preserving delicate essential oils, or refining specialty chemicals, our systems deliver precision without compromise. With ≤0.1Pa vacuum control, 316L stainless steel construction, and ABB automation, our solutions ensure efficiency, compliance, and scalability.

Core Advantages

- ✅ Ultra-Low Thermal Stress: 3-stage cold traps retain volatile compounds like terpenes and APIs, reducing thermal degradation to <0.1%.

- ✅ Pharma-Grade Compliance: Tri-clamp sanitary design with CIP/SIP capabilities meets FDA, EU GMP, and ISO 13485 standards.

- ✅ Scalable Configurations: Pilot-scale (10L/hr) to industrial (500L/hr) capacities, with modular upgrades for future expansion.

- ✅ Energy Efficiency: Hybrid oil-free vacuum pumps and heat recovery modules cut energy costs by up to 35%.

- ✅ Global Certifications: CE, ASME, EHEDG, and NSF-approved systems for seamless market approvals.

Industry-Specific Solutions

🧪 Pharmaceuticals & Nutraceuticals

Isolate CBD, Vitamin E, or APIs with ≥99.9% purity while adhering to strict batch consistency. Our GMP-certified systems include full IQ/OQ/PQ validation packages and ±0.5°C temperature control.

🌿 Essential Oils & Botanicals

Preserve aromatic profiles with 40–80°C processing and inert gas blanketing. Glass-lined condensers and aroma-lock cold traps ensure >99% terpene retention.

🔬 Specialty Chemicals

Process high-boiling-point materials (up to 450°C) using wiped-film technology. Hastelloy construction resists corrosion from aggressive feedstocks.

🥄 Food & Flavorings

HACCP-certified Industrial Molecular Distillation systems for edible oils, stevia, or Omega-3 concentrates. Sanitary finishes (Ra ≤0.8 μm) eliminate contamination risks.

Technical Specifications

| Feature | Specification |

|---|---|

| Evaporation Area | 0.2m² – 12m² |

| Temperature Range | Ambient – 350°C (±0.5°C) |

| Vacuum System | Oil-free diaphragm + liquid nitrogen traps |

| Materials | SS316L, Hastelloy, Glass-Lined |

| Automation | ABB PLC with SCADA integration |

Trusted by Global Leaders

- Pharma Case Study: A European API manufacturer boosted yield by 22% using our cGMP short-path distiller.

- Food Industry Success: A U.S. Omega-3 producer achieved FSSC 22000 compliance in 3 months post-installation.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do your systems minimize heat damage?

Our short-path design reduces molecular travel distance, while 0.1Pa vacuum lowers boiling points.

Are your systems FDA-approved?

Yes. We provide full documentation for FDA 21 CFR Part 11 and EU Annex 11 compliance.

Can I upgrade from pilot to production scale?

Absolutely. Modular designs let you scale capacity without replacing core components.

What upkeep is required?

Annual diaphragm pump inspections and quarterly gasket checks ensure leak-free operation.

Contact Us

Need an Industrial Molecular Distillation Custom Solution?

Email info@welloneupe.com for OEM quotes or technical support.