Thin Film Distillation System

2) Continuous feed/discharge gear pump.

3) High vacuum, no-load system vacuum ≤ 0.1Pa.

4) High temperature and corrosion resistant stainless steel material.

5) Supports OEM and ODM.

6) CE, ISO, UL, SGS, ATEX, IEC certification.

7) 1 year warranty and quality commitment.

8) PLC fully automatic

9) Material supports Hastelloy alloy

- Product Description

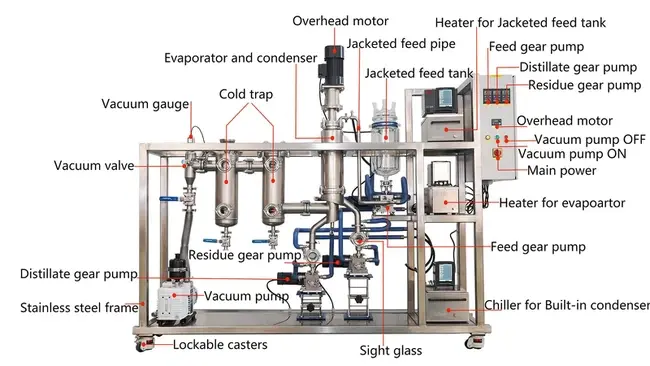

Thin Film Distillation System Description

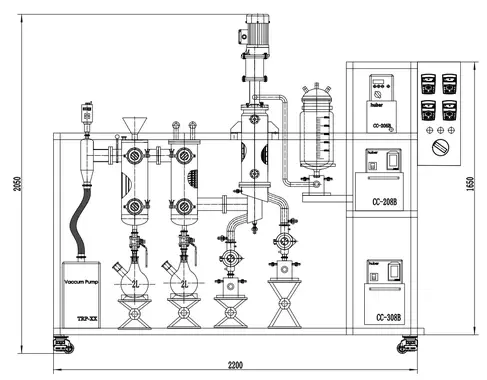

The Well One Thin Film Distillation System with an evaporation area of 0.15 ㎡, a heating temperature of 300 ℃, and a system vacuum of ≤ 0.1Pa; 500g to 5000g of samples can be processed per hour; The material flows through the pipeline jacket for heat tracing, and is individually controlled in sections to process materials with a melting point higher than room temperature; The main unit, heating and cooling, and vacuum unit are integrated in one bracket, with a compact structure and small space occupation. They can be placed in ventilated cabinets or clean workshops, making them the preferred model for teaching and research institutions.

Workflow Principles

The sample is placed in a jacketed container and transported to the Thin Film Distillation System evaporator through a feeding gear pump; The outer layer of the evaporator is a heating cylinder, the middle is a condenser, and between the heating cylinder and the condenser is a film forming distributor; After the sample enters the evaporator, it is evenly distributed on the surface of the heating cylinder through a film forming distributor. The low boiling substances in the sample are vaporized at a preset temperature and collected by the middle condenser for cooling; Low boiling point substances accumulate at the bottom of the middle condensation, and are continuously output to the evaporator using a product gear pump. High boiling point substances accumulate at the bottom of the heating cylinder, and are output to the evaporator using a residual gear pump; The vacuum pump expels the gas from the Wiped Film Distillation Equipment system and maintains a low pressure to reduce the boiling point of the sample; One heating circulator is used for heating the evaporator, one heating circulator is used for tracing the material through the pipeline, and one heating circulator is equipped with a heat exchange coil inside the heating circulator, which can be cooled by cooling medium and used for constant temperature cooling of the condenser inside the evaporator; Two cold traps are used to cool and collect low point solvents, moisture, etc. that cannot be completely cooled by the internal cooler, protecting the vacuum pump. It can be cooled with dry ice or liquid nitrogen, or it can be prepared with a refrigerator for cooling.

Products Parameter

Model | WMD-15 |

Throughput | 500g~5000g per hour |

Feeding Tank | 5L Jacketed tank |

Feed gear pump | 3L~10L/H , High precision gear pump,200W variable frequency speed regulation |

Evaporator area | 0.15㎡ Evaporation area |

Internal cooling area | 0.3㎡ Inter cooler area |

Evaporator diameter | 125mm inner diameter |

Sealing method | Magnetic sealing |

Scraper form | Wiper or Roller |

Discharge gear pump(Residue) | 3L~10L/H , High precision gear pump,200W variable frequency speed regulation |

Discharge gear pump(Distillate) | 3L~10L/H , High precision gear pump,200W variable frequency speed regulation |

All material pipelines | Jacketed insulation |

Materials | SS316L |

Heater(Main Evaporator) | RT-300℃/Heater power 15kw/Circulation 50L/min |

Heater(Material insulation) | RT-200℃/Heater power 10kw/Circulation 50L/min |

Heater & Chiller(Inter condenser) | -20℃-200℃/Heater power 6kw/Cooler power 11kw |

Chiller(External condenser) | -80℃-RT/-40℃ power 4.1kw/-80℃ power 1.2kw |

Vacuum Pump VP01+VP02 | Vane Vacuum Pump:TRP-48(16L/S)/Turbo Pump:TYFB-600(600L/S) |

Products Application

University teaching: Molecular Distillation Equipment is an important method for the separation of organic compounds, and is a science that students from departments such as the School of Organic Chemistry, the School of Bioengineering, the School of Life Sciences, the School of Pharmaceutical Engineering, and the School of Materials must master. An excellent science university must have a molecular distillation teaching machine.

Research institutions: Molecular distillation has been applied to professional research institutions such as lubricants, energetic materials, TFT materials, OLED materials, pharmaceuticals, food, spices, etc.

High tech company R&D departments: BASF, Sinopec, Dow, PetroChina, Hengli Petrochemical, Wanhua Chemical, Sasol and other companies have already used molecular distillation equipment for research and development.

Newly established entrepreneurial company: A newly established company that is unfamiliar with product processes, has unclear market expectations, and lacks funds. It needs to first purchase a set of experimental molecular distillation for process research and small-scale production.

Products Details

A. Glass visualization sample storage tank, which can observe the remaining information of the sample;

B. Material pipeline heat tracing design makes the experimental process of materials with melting points higher than room temperature smoother;

C. Famous brand heating circulator with precise temperature control, capable of remote communication and operation;

D. High precision gear pump, precise delivery and measurement under high pressure difference;

E. The vacuum exhaust port is equipped with an oil separation collector to protect the use space from pollution and safeguard the health of the operator.

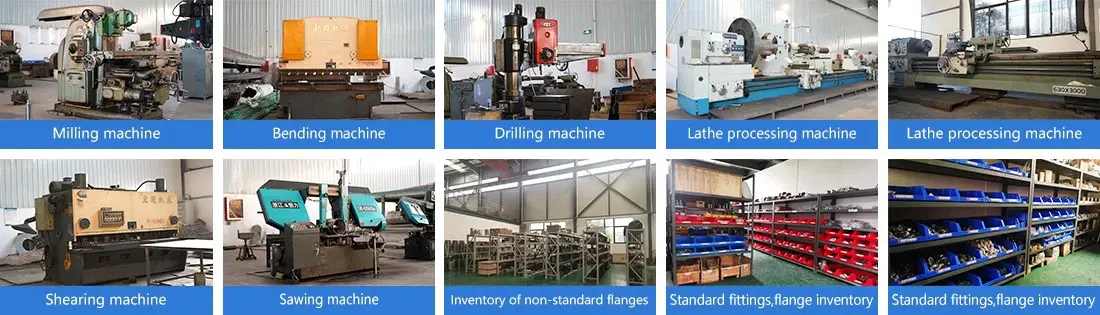

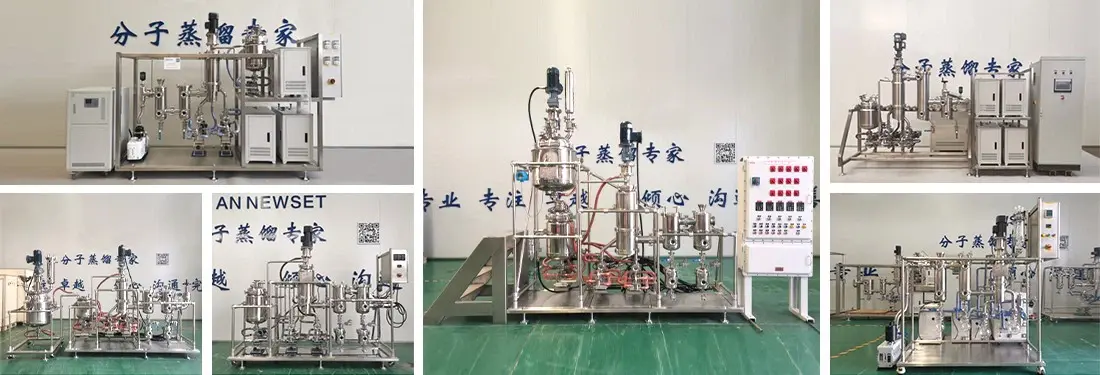

Our Factory

The company has a senior design team and a processing and manufacturing team, including process development, equipment design, 3D modeling and other designers, dedicated to the research and production of new synthesis and purification separation equipment. The company has an independent research and development laboratory, which can provide customers with comprehensive services such as feasibility research, process development, laboratory testing, and pilot testing. According to the experimental results, the company ensured the production capacity and product quality of the customer's production equipment. After 17 years of effort, we focus on providing users with a series of products such as experimental level Thin Film Distillation Systems, pilot level molecular distillation devices, industrial level molecular distillation devices, and multi-level continuous use systems.

1.Exhibition site:

2. R & D Team:

3.CNC machining center:

4.Processing machine:

5.Assembly process and finished products:

6.OEM&ODM Customization Case:

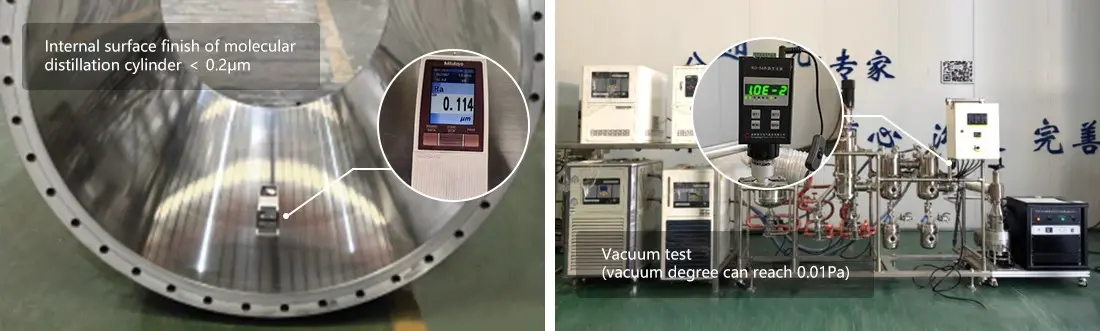

7.Surface finish and vacuum degree:

Products Qualification

UL certification ensures that electrical appliances have undergone rigorous testing and evaluation to meet specific safety requirements. It involves assessing factors such as electrical safety, fire resistance, mechanical stability, and potential hazards associated with the use of the appliance.

By complying with UL certification, manufacturers demonstrate their commitment to producing safe and reliable electrical appliances. Consumers can have confidence that UL-certified appliances have met stringent safety standards and are less likely to pose risks such as electric shock, fire, or other hazards.

It's important to note that different countries and regions may have their own certification standards. In addition to UL, there are other recognized certification bodies worldwide, such as CSA (Canada), CE (European Union), and CCC (China), among others. Manufacturers often obtain certifications from multiple organizations to ensure compliance with various national and international safety standards.

Package

Complies with international export wooden box packaging (non fumigation).

Contact Us

Request Technical Dossier & Bulk Pricing For Thin Film Distillation System → info@welloneupe.com