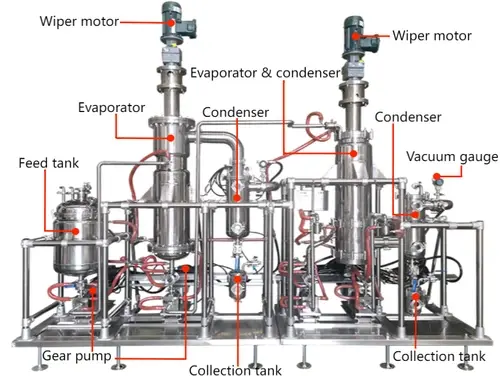

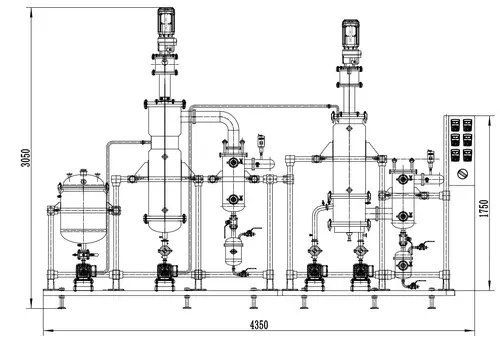

Stainless Steel Short Path Molecular Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) High efficiency evaporation, strong adaptability, easy operation

- Product Description

Stainless Steel Short Path Molecular Distillation Systems: Precision Separation for Heat-Sensitive Compounds

Stainless Steel Short Path Molecular Distillation technology revolutionizes how industries purify sensitive compounds. Designed with pharmaceutical-grade 316L stainless steel, our systems ensure corrosion resistance, CIP/SIP compatibility, and compliance with global standards. By operating at low temperatures (<100°C), these units preserve the integrity of heat-sensitive materials like cannabinoids, essential oils, and APIs, delivering ≥99.9% purity. Whether scaling lab processes or optimizing production throughput, our modular designs adapt to your needs.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | 316L Stainless Steel (ASME/BPE) |

| Temperature Range | 40°C – 200°C (±1°C control) |

| Vacuum Level | ≤0.001 mbar |

| Throughput Capacity | 5L/hr – 500L/hr (Customizable) |

| Certifications | CE, FDA, ISO, GMP, ATEX |

| Warranty | 1 Year + Lifetime Technical Support |

Key Benefits for Your Industry

🏥 Pharmaceuticals

- Purify APIs, peptides, or solvents with GMP-compliant systems.

- Reduce thermal degradation risks during high-purity separation.

🌿 Essential Oils & Botanicals

- Preserve terpenes and CBD isolates using low-temperature operation (≤50°C).

- Double yield with stable vacuum performance.

🧪 Specialty Chemicals

- Achieve precise molecular weight fractionation using PTFE wipers.

- Handle viscous resins or polymers without foaming.

🥑 Food & Nutraceuticals

- Concentrate omega-3s or vitamin E with food-grade materials.

- Eliminate cross-contamination with allergen-free surfaces.

⚡ Biofuels

- Purify pyrolysis oils or biodiesel feedstocks efficiently.

- Reduce energy consumption by 18% with optimized heat exchangers.

Why Choose Our Systems?

🔧 Precision Engineering

Advanced temperature control and short-path design minimize molecular travel distance, enhancing separation accuracy.

🛠️ Customizable Configurations

Choose single-stage, dual-stage, or three-stage setups tailored to your viscosity, throughput, and purity goals.

🌐 Global Compliance

Meet FDA 21 CFR Part 11, EU Annex 11, and ISO 13485 standards effortlessly. Validation documentation (IQ/OQ/PQ) included.

⚡ Faster Turnaround

Our zero cold traps design accelerates solvent recovery by 30%, reducing batch processing time.

Trusted by Industry Leaders

- Pharma Client X: Achieved 99.95% API purity with 18% energy savings.

- Essential Oil Producer Y: Doubled terpene yield using ≤50°C distillation.

- Biofuel Manufacturer Z: Scaled pyrolysis oil processing by 200% with modular systems.

Global Support

- 24/7 Remote Diagnostics: Resolve issues instantly.

- <48-Hour Onsite Support: Guaranteed rapid response.

Upgrade to Stainless Steel Short Path Molecular Distillation systems that combine durability, compliance, and precision. Let’s refine your future together!

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does short-path differ from wiped-film distillation?

Short-path systems reduce molecular travel distance, ideal for heat-sensitive materials. Wiped-film suits higher throughput but risks thermal degradation.

Can your equipment handle cannabis crude oil?

Yes! Our anti-foaming rotor manages viscous materials up to 50,000 cP without clogging.

What’s the lead time for a 200L/hr GMP unit?

Standard units ship in 8–10 weeks. Expedited options available.

How do you ensure hygiene in edible oil processing?

316L stainless steel surfaces, nitrogen blanketing, and EHEDG-certified seals prevent oxidation and contamination.

Contact Us

Ready to Optimize Your Stainless Steel Short Path Molecular Distillation Process?

📩 Contact Us Today!

Email info@welloneupe.com to discuss custom configurations.