Wiped Film Distiller

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) UL/CE configurations available

- Product Description

High-Purity Wiped Film Distillers for Heat-Sensitive & High-Value Compound Separation

Precision Molecular Distillation with ≤1°C Thermal Degradation, Scalable for Industrial Demands

Unlock Precision Separation for Your Industry

When handling delicate compounds, the Wiped Film Distiller stands as your trusted partner. Designed for industries where purity and thermal control are non-negotiable, our systems ensure minimal degradation while maximizing yield. Whether you’re refining pharmaceuticals, preserving essential oils, or scaling biodiesel production, this technology adapts to your needs. Let’s explore how it elevates your processes.

Key Applications by Industry

- Pharmaceuticals: Isolate APIs, peptides, and cannabinoids without thermal breakdown.

- Chemicals: Refine polymers, specialty lubricants, and UV inhibitors at >99.9% purity.

- Essential Oils: Preserve terpenes and volatile aromatics with low-temperature short-path distillation.

- Biofuels: Efficiently separate methyl esters, glycerol, and fatty acid derivatives.

- R&D: Modular units for process optimization studies and pilot-scale trials.

Why Our Wiped Film Distiller Outperforms?

Core Technology Breakdown

- Short Residence Time (10-60 seconds): Protects heat-sensitive materials like enzymes and fragrances.

- High Vacuum (0.001-1 mbar): Lowers boiling points, reducing energy consumption by up to 40%.

- Uniform Film Distribution: Maximizes evaporation efficiency with mechanically wiped surfaces.

- Pharma-Grade Compliance: Wiped Film Distiller all-metal seals and CIP/SIP compatibility meet FDA and GMP standards.

Performance Comparison

| Feature | Wiped Film Distiller | Rotary Evaporation | Falling Film |

|---|---|---|---|

| Temp Range | 50°C–300°C | 30°C–150°C | 80°C–250°C |

| Throughput Capacity | 100mL–20,000L/hr | 1L–500L/hr | 500L–5,000L/hr |

| Purity Level | >99.9% | 85–95% | 90–98% |

| Energy Efficiency | High | Low | Moderate |

Tailored to Your Workflow

Modular Configuration Options

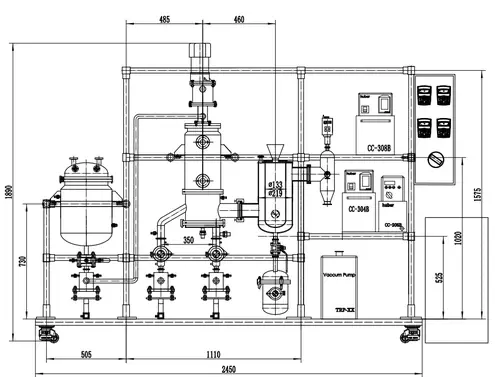

- Evaporation Surface: 0.1m² to 10m² (lab to industrial scale).

- Materials: 316L stainless steel, Hastelloy, or glass-lined interiors.

- Automation: Integrate PAT tools for real-time quality monitoring.

- Add-ons: Cold traps, multi-stage condensers, solvent recovery modules.

Trusted by Global Leaders

Compliance & Certifications

- Standards: ASME BPE, ATEX Directive, GAMP5, FDA 21 CFR Part 11.

- Certifications: CE, ISO 9001/13485, UL, SGS, ECOCERT.

Client Success Stories

- Pharma: 40% yield boost in mRNA lipid nanoparticle purification.

- Biofuels: 98% fatty acid separation achieved in biodiesel refining.

- Essential Oils: Maintained 100% organic certification for lavender extracts.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does a product prevent thermal degradation?

Our rotor design ensures materials spend <60 seconds on heated surfaces, paired with precise temperature control (±1°C).

Can it handle high-viscosity chemicals like polymers?

Yes! Optimized wipers process materials up to 50,000 cP without clogging.

Is the system scalable from R&D to production?

Absolutely. Start with a 0.1m² bench unit and upgrade to 10m² without redesigning workflows.

Contact Us

Ready to Transform Your Wiped Film Distiller Process?

Contact Us: Email info@welloneupe.com for immediate inquiries.