Short Path Distillation System

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Free technical support

- Product Description

High-Purity Short Path Distillation Systems for Pharma, Biofuels, Cosmetics & More

When precision matters, our Short Path Distillation System delivers unmatched separation efficiency for heat-sensitive compounds. Designed for industries ranging from pharmaceuticals to renewable energy, this system ensures optimal purity (up to 99.9%) while minimizing thermal degradation. Whether you’re refining essential oils for cosmetics or recovering solvents from industrial waste, our technology adapts to your needs with modular configurations and rigorous compliance.

Why Choose Our Short Path Distillation System?

- Precision Temperature Control

Maintain ±1°C stability to preserve delicate compounds like terpenes or cannabinoids, ideal for cosmetics and pharmaceutical applications.

- Regulatory Compliance

Meet FDA, CE, ATEX, and ISO standards effortlessly—perfect for global distributors and manufacturers.

- Scalable Configurations

Transition seamlessly from lab-scale R&D (1L/hr) to industrial production (500L/hr) with modular setups.

- Energy Efficiency

Reduce operating costs by 30% with low thermal decomposition designs—critical for eco-conscious biofuel producers.

- Corrosion-Resistant Build

316L stainless steel or glass components withstand aggressive chemicals, ensuring longevity in harsh environments.

Technical Specifications Tailored to Your Industry

| Feature | Pharma/Chemical | Biofuel Production | Waste Recycling |

|---|---|---|---|

| Vacuum Range | 0.001–1 mbar | 0.01–0.5 mbar | 0.1–5 mbar |

| Throughput | 50–200L/hr (continuous) | 100–500L/hr (batch) | 20–100L/hr (viscous) |

| Customization | GMP-compliant automation | ASTM-grade purity modules | Explosion-proof designs |

Industry-Specific Solutions

1. Pharmaceutical & Chemical Distributors

Ensure GMP compliance and resale-ready Short Path Distillation System with full documentation (DQ/IQ/OQ/PQ). Our 316L stainless steel construction minimizes downtime in API production.

2. Biofuel Producers

Achieve >99.5% biodiesel purity with rapid cycle times and integrated cooling loops. Real-time PLC adjustments optimize vacuum pressure for volatile bio-oils.

3. Cosmetics Manufacturers

Preserve fragrance integrity using glass-coated internals and inert gas purging. Our systems reduce oxidation by 90% compared to traditional methods.

4. Waste Recyclers

Recover 95%+ solvents from complex waste streams with abrasion-resistant wipers and automated residue discharge—no clogging, even with pyrolysis oil.

5. Academic & Government Labs

Benchtop models with open-source software integration allow parameter flexibility for nanomaterials or experimental feedstocks.

Trusted Globally, Built for Excellence

Our systems adhere to regional standards: REACH (EU), FDA (US), and ECOCERT (cosmetics). All units include CE/UL certifications and a 1-year warranty.

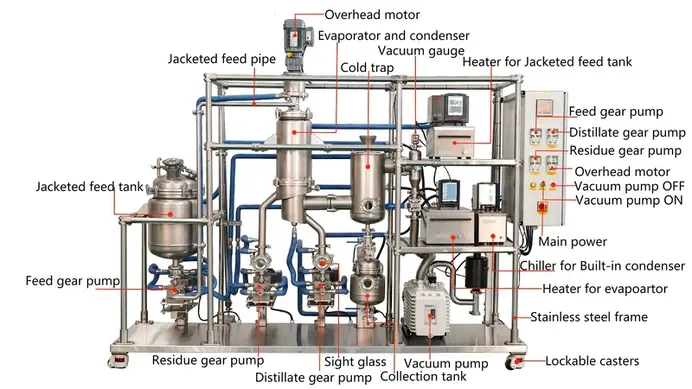

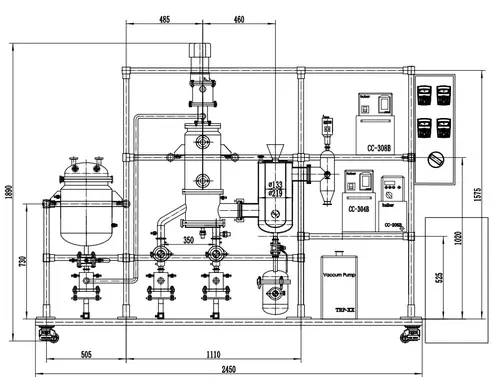

Modular Design for Future-Proof Upgrades

Core Components: Evaporator, condenser, feed tank

Optional Add-Ons:

- CIP cleaning systems

- IoT performance monitoring

- Multi-stage distillation kits

What Our Clients Say?

> “We’ve reduced energy costs by 35% while scaling up cannabis distillate production. The 24/7 technical support is unmatched.”

— Biofuel Producer, North America

> “Their glass-lined SPD system preserved our essential oils’ potency—critical for luxury skincare lines.”

— Cosmetics Brand, Europe

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

What certifications support GMP compliance?

Our systems are CE, ISO 9001, and ASME certified, with full validation packages for FDA audits.

Can the system handle temperature-sensitive bio-oils?

Yes! Precise vacuum control (±0.05 mbar) and rapid cooling ensure minimal thermal stress.

How is thermal degradation prevented?

Quartz glass condensers and <1-minute residence times preserve volatile compounds.

What’s the maximum solvent recovery rate?

Systems achieve 95–98% recovery for mixed volatiles, even with viscous feedstocks.

Are benchtop models customizable?

Absolutely! Swap components for nano-material studies or integrate third-party sensors.

Contact Us

Contact Us Today for a Short Path Distillation System:

Email: info@welloneupe.com