Industrial Short Path Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) We provide customers with turnkey solutions

- Product Description

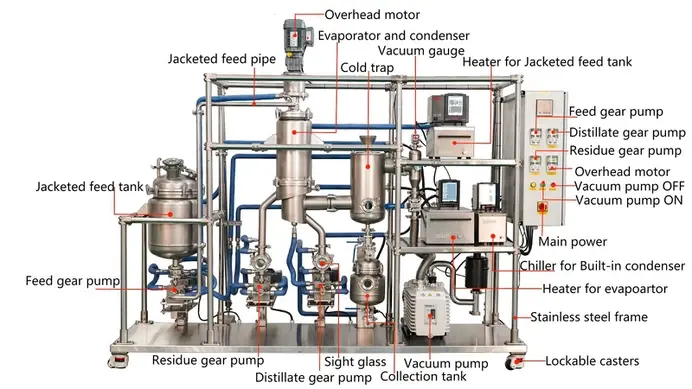

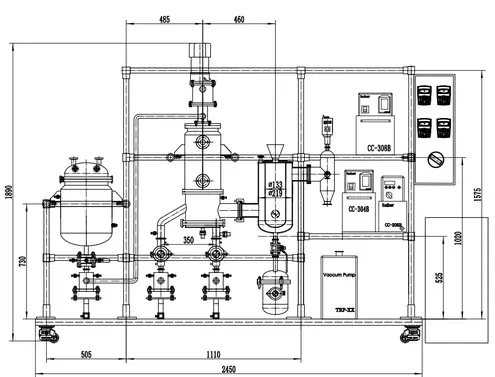

Industrial-Grade Short Path Distillation Systems for Precision Separation at Scale

Engineered for high-purity compound recovery, thermal-sensitive material preservation, and large-volume processing in GMP/ISO-compliant workflows.

Industrial Short Path Distillation is the gold standard for industries demanding ultra-pure separations without compromising delicate compounds. Whether you’re refining cannabinoids, purifying pharmaceutical intermediates, or isolating volatile essential oils, our systems deliver unmatched precision, energy efficiency, and scalability. With CE, ISO, and FDA certifications, we ensure your processes meet global regulatory benchmarks while maximizing yield.

Applications by Industry

Pharmaceutical API & Intermediate Purification

Achieve ≥99.9% purity for heat-sensitive active ingredients with GMP-compliant setups. Our systems minimize thermal degradation, ensuring compliance with FDA and EMA standards.

Terpene Isolation & Botanical Extract Refinement

Preserve volatile aromas and bioactive compounds using ±0.5°C temperature control and borosilicate glass surfaces. Ideal for USDA Organic and ECOCERT workflows.

Petrochemical/Specialty Polymer Fractionation

Handle corrosive, high-viscosity materials with Hastelloy-coated components and anti-coking rotor designs. ATEX-certified for explosive environments.

Cannabinoid Distillation & THC Remediation

Remove THC to <0.3% while recovering 95%+ cannabinoids via multi-stage setups. Fully compliant with Health Canada and EU-GMP requirements.

R&D Pilot-Scale Material Testing

Compact, modular Industrial Short Path Distillation systems with 0.1–5L capacity and real-time data logging for academic and industrial research.

Why Choose Our Industrial Short Path Distillation Systems?

- Material Versatility: SS316L, borosilicate glass, or PTFE-lined options.

- Vacuum Efficiency: <0.001 mbar pressure for rapid, low-temperature separation.

- Scalability: Evaporation areas from 0.1m² (lab) to 5.0m² (production).

- Certifications: CE, ATEX, ASME, ISO 9001/13485, and regional cannabis licenses.

Performance Comparison

| Feature | Our Systems | Traditional SPD | Rotary Evaporators |

|---|---|---|---|

| Cannabinoid Recovery | 95%+ | 80-85% | <70% |

| Energy Consumption | 30% Less | Standard | 50% Higher |

| Maintenance Cycles | 1,200 Hours | 500 Hours | 200 Hours |

Trusted by Global Leaders

- Fortune 500 Chemical Manufacturers: 20-30% operational cost savings.

- EU Botanical Extractors: Zero degradation in terpene profiles.

- North American Cannabis Processors: 23% higher THC remediation efficiency.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do you prevent thermal degradation in sensitive compounds?

Our automated PID controllers maintain ±0.5°C accuracy, while short-path design reduces exposure time by 70% vs. traditional methods.

Can systems handle high-viscosity petrochemicals?

Yes. Jacketed feed preheaters and PTFE wipers ensure smooth processing of materials up to 50,000 cP.

What certifications apply to pharmaceutical use?

All pharma modules are GMP-ready with CIP/SIP capabilities and FDA CFR Part 11 compliance.

Do you offer pilot-scale configurations?

Yes. Our benchtop systems (0.1m²) include interchangeable flasks and lab-friendly controls.

How fast is installation?

Most systems are operational within 8 weeks, with on-site support in 30+ countries.

Contact Us

Email info@welloneupe.com for a free Industrial Short Path Distillation ROI estimate or live demo!