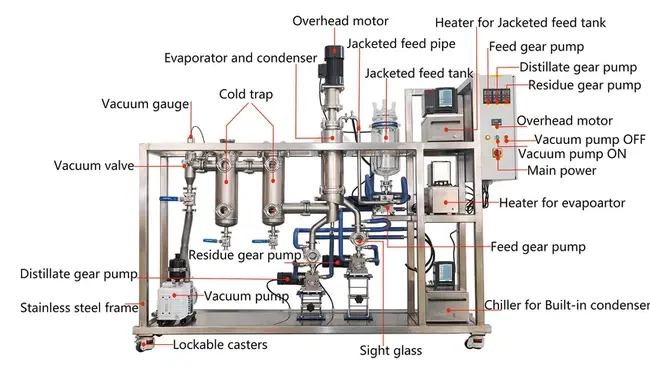

Short Path Distillation Set

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Delivery time: 2 weeks.

- Product Description

High-Purity Short Path Distillation Systems for Precision Separation

Optimize Thermally Sensitive Compound Recovery for Pharmaceuticals, Extracts, Chemicals & More

If you work with heat-sensitive compounds, a Short Path Distillation Set is your gateway to achieving ultra-pure separations without compromising delicate materials. Designed for industries like pharmaceuticals, essential oils, and petrochemicals, these systems combine advanced vacuum technology, corrosion-resistant materials, and modular scalability to deliver unmatched precision.

Why Choose Our Short Path Distillation Sets?

- Preserve Heat-Sensitive Compounds: Operate below 100°C to protect APIs, terpenes, and monomers from thermal degradation.

- Ultra-High Vacuum (0.001–10 mbar): Achieve faster separation cycles with minimal energy consumption.

- Scalable Designs: Choose from 5L benchtop units to 500L industrial systems, all built with SS316L or glass for chemical compatibility.

- GMP/ISO-Ready: Validate processes effortlessly with documentation support and cleanroom assembly options.

- 5-Stage Fraction Collection: Attain ≥99.5% purity for critical applications like cannabinoid isolation or solvent recycling.

Industry-Specific Solutions

Pharmaceuticals

Purify APIs, recover solvents, and isolate cannabinoids while meeting FDA 21 CFR Part 11 compliance.

Essential Oils

Retain 98% of terpenes in cannabis oil or citrus extracts with glass-only pathways and odor-resistant seals.

Petrochemicals

Separate silicone compounds or monomers using PTFE wipers and explosion-proof configurations.

Waste Management

Recover >95% of solvents like acetone or ethanol with anti-clogging designs and integrated recovery modules.

Technical Specifications

| Model | Capacity | Temp Range | Vacuum Range | Material | Certifications |

|---|---|---|---|---|---|

| SPD-5L | 5L/hr | 20–250°C | 0.001–10 mbar | SS316L/Glass | CE, ISO 9001 |

| SPD-20L | 20L/hr | 20–300°C | 0.001–10 mbar | SS316L/Glass | CE, GMP |

| SPD-500L | 500L/hr | 20–350°C | 0.001–10 mbar | SS316L/Glass | CE, ATEX |

Trusted by Global Innovators

"Our SPD-100L system reduced API purification time by 40% compared to rotary evaporation." – Pharma Lab Director, Germany

"Terpene retention in our cannabis oil reached 98% – a game-changer for product quality." – Extract Producer, Canada

Compliance & Certifications

Our Short Path Distillation Sets meet:

- CE, ISO 9001/13485: For industrial and laboratory use.

- GMP/FDA: Validated for pharmaceutical and cosmetic production.

- REACH/ROHS: Environmentally safe and chemical-resistant.

Short Path vs. Alternatives

| Feature | SPD | Rotary Evaporation | Wiped Film |

|---|---|---|---|

| Purity | ≥99.5% | 85–90% | 90–95% |

| Temp Sensitivity | Excellent | Moderate | Good |

| Scalability | 5L–500L | Limited | 50L–1000L |

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does a product prevent thermal degradation?

By maintaining high vacuum levels (down to 0.001 mbar), boiling points are drastically reduced, enabling low-temperature separations.

Can I integrate your systems with existing solvent recovery lines?

Yes – our modular designs include standardized fittings for seamless integration.

What’s the lead time for a custom GMP-grade unit?

Standard configurations ship in 2 weeks; customized units require 4–6 weeks.

Are your systems suitable for high-viscosity extracts?

Absolutely. Our anti-clogging wipers and gear pump discharge handle viscosities up to 50,000 cP.

Contact Us

Ready to Elevate Your Short Path Distillation Set Process?

Contact Us: info@welloneupe.com