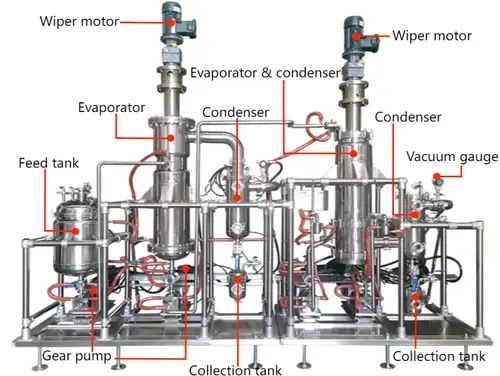

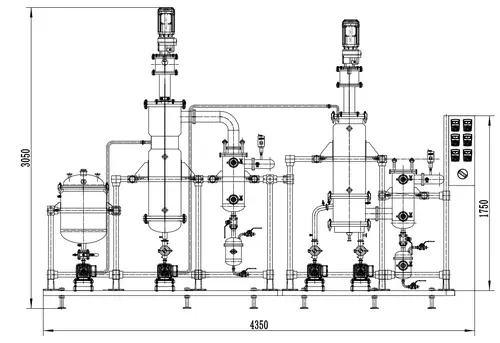

Short Path Distillation Device

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Factory workshop live show support

- Product Description

Short Path Distillation Device: High-Purity Short Path Distillation Systems for Precision & Scalability

GMP/CGMP-compliant, -70°C to 300°C range, modular configurations for APIs, botanicals, biofuels, and R&D

When purity and precision matter, a Short Path Distillation Device is your go-to solution for separating heat-sensitive compounds without degradation. Ideal for pharmaceuticals, essential oils, and green chemistry, our systems combine cutting-edge vacuum control, corrosion-resistant materials, and smart automation. Whether you’re scaling production or refining delicate fragrances, this technology ensures consistent results. Let’s explore how it can elevate your process.

Why Industries Trust Our Distillation Systems

Preserve Delicate Compounds

- Pharmaceuticals: Achieve >99.9% purity for APIs like cannabinoids or lipid nanoparticles with ±0.5°C temperature stability.

- Essential Oils: Capture volatile terpenes using -70°C cold traps and borosilicate glass components to prevent oxidation.

- Biofuels: Fractionate viscous feedstocks efficiently while recovering 95%+ solvents for eco-friendly operations.

Built to Last, Designed to Adapt

- Materials: Choose SS316L, glass-lined, or hybrid vessels for corrosive or high-purity applications.

- Smart Monitoring: IoT sensors track vacuum levels (down to 0.001 mbar) and send real-time alerts.

- Scalable: Upgrade from 5L benchtop units to 500L/day production systems seamlessly.

Certifications You Can Rely On

Our Short Path Distillation Device meets:

- Pharma: FDA 21 CFR Part 11, EU GMP, ISO 13485.

- Industrial: CE, ATEX, ASME BPE.

- Sustainability: ISO 50001, USDA BioPreferred.

Custom Solutions for Your Workflow

White-Label Partnerships

- Rebrand control interfaces and housings.

- Modify flange sizes, voltage (110V–480V), and automation protocols.

Calculate Your Savings

Compare traditional vs. short-path distillation:

- Energy Use: 40% lower consumption per liter.

- Yield: 15–30% higher recovery of high-value compounds.

- Labor: Reduce manual checks by 70% with self-cleaning CIP/SIP cycles.

Trusted by Leaders in Innovation

Case Study: A European cannabis producer achieved 99.8% isolate purity and cut processing time by 50% using our modular SPD system.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How quickly can I integrate this into my existing setup?

Share your P&ID diagrams for a free compatibility review. Most systems connect within 48 hours.

What’s the lead time for a 50L semi-automatic unit?

12 weeks, with live production tracking updates.

Can it handle high-viscosity materials like pyrolysis oil?

Yes! Our rotor scrapers maintain thin, turbulent films even for viscous feeds.

Contact Us

Ready to Transform Your Short Path Distillation Device Process?

📩 Email info@welloneupe.com for a tailored quote or live demo.