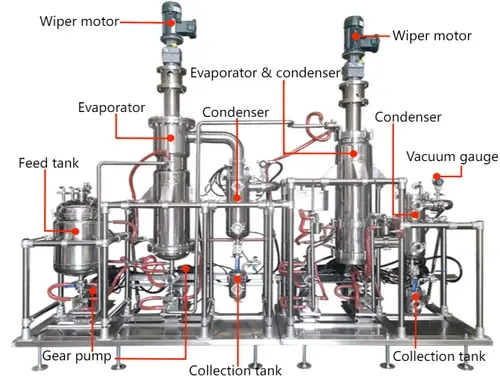

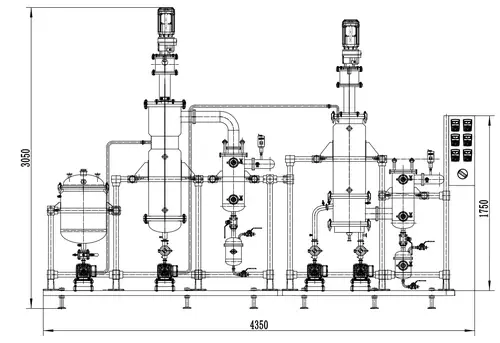

Dual Stage Wiped Film Distillation

2) Continuous production without stopping the machine.

3) Differentiated vacuum meets different operating conditions.

4) High temperature and corrosion resistant stainless steel material.

5) Support customization according to process requirements.

6) Electrical appliances meet UL, ATEX, IECEx, and 3C certifications.

7) 1-year warranty with 24-hour online technical support.

- Product Description

Dual Stage Wiped Film Distillation: Precision Separation for Demanding Industries

When purity and efficiency matter, Dual Stage Wiped Film Distillation systems deliver unmatched performance for pharmaceutical, cannabis, petrochemical, and specialty chemical applications. By combining thin-film evaporation with a secondary wiped-film stage, this technology achieves ultra-high separation accuracy (up to 99.9% purity) while protecting heat-sensitive compounds from degradation. Whether you’re refining APIs, isolating terpenes, or recovering solvents, our GMP-compliant systems adapt to your exact needs with scalable, energy-efficient solutions.

Why Choose Our Dual Stage Wiped Film Distillation Systems?

1. Thermal Protection for Sensitive Materials

Preserve delicate compounds like terpenes, cannabinoids, or essential oils with precise temperature control (as low as 40°C under vacuum). Dual-stage processing minimizes heat exposure, ensuring bioactive retention even in oxygen-sensitive environments.

2. Two-Stage Purity Optimization

Achieve sharper fraction cuts than single-stage systems. The first stage removes bulk impurities, while the second refines output to pharmaceutical-grade standards—ideal for API intermediates or high-value isolates.

3. 90%+ Solvent Recovery

Cut operational costs with integrated solvent reclamation. Our systems recover over 90% of ethanol, hexane, or other solvents, reducing waste and meeting stringent emissions regulations.

4. Fouling-Resistant Design

Handle heavy hydrocarbons, waxes, or polymer-rich feedstocks using abrasion-resistant rotor blades and self-cleaning wipers. This ensures continuous operation without downtime for manual cleaning.

Technical Specifications

| Parameter | Range |

|---|---|

| Evaporation Area | 0.5 – 10 m² |

| Operating Temperature | 40°C – 200°C |

| Vacuum Level | ≤0.001 mbar |

| Materials | 316L SS, Hastelloy, Glass-Lined |

| Certifications | GMP, ASME, ATEX, ISO 9001 |

Industry-Solved Challenges

Pharmaceuticals

- Purify heat-sensitive APIs without thermal degradation.

- cGMP-compliant designs with full audit documentation.

Cannabis/CBD

- Isolate THC-free CBD distillate (>99% purity).

- Terpene preservation with nitrogen-blanketed stages.

Essential Oils

- Prevent oxidation in citrus or floral extracts.

- Food-grade 316L stainless steel construction.

Petrochemicals

- Distill viscous lubricants (up to 1,000 cSt).

- Anti-coking rotors for heavy hydrocarbon processing.

Recycling

- Reclaim solvents with <50mg/Nm³ VOC emissions.

- Sludge-ready configurations for polymer residues.

Trusted Compliance & Support

All systems meet:

- Pharma: EU GMP

- Chemicals: PED 2014/68/EU

- Safety: ATEX Zone 1, UL/CE certifications

Backed by 24/7 technical support and a 1-year warranty, we ensure your Dual Stage Wiped Film Distillation system operates flawlessly.

Success Stories

- CBD Producer: Increased isolate yield by 30% while reducing ethanol consumption by 45%.

- Essential Oil Brand: Achieved 99.5% linalool retention in lavender oil with zero oxidation.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does dual-stage reduce processing time?

By separating bulk and fine impurities in two sequential stages, total cycle times drop by up to 40% compared to single-stage units.

Can this integrate with existing solvent recovery?

Yes—our systems support custom retrofitting for seamless compatibility with your current setup.

What maintenance is required?

Automated self-cleaning reduces manual interventions. Annual inspections and rotor blade checks are recommended.

Contact Us

Need a Tailored Solution?

Email info@welloneupe.com to discuss your Dual Stage Wiped Film Distillation project. Let’s optimize your distillation process together!