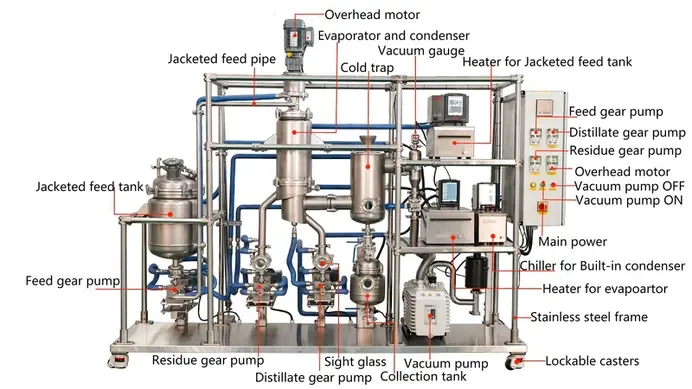

Commercial Distillation Equipment

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) flexible design

- Product Description

Precision Commercial Distillation Equipment for Diverse Industries

When your business requires unmatched purity, efficiency, and reliability, Commercial Distillation Equipment from [Your Brand] delivers. Designed for industries ranging from craft distilleries to pharmaceutical giants, our systems combine cutting-edge technology with industry-specific expertise. Whether you’re refining spirits, extracting essential oils, or producing biofuels, our ISO-certified distillation solutions ensure optimal performance while meeting strict global standards like CE, ASME, and GMP.

Why Choose Our Distillation Systems?

- 99.9% Purity Output: Achieve pharmaceutical-grade separation for sensitive compounds.

- Energy Savings Up to 40%: Integrated vapor recovery reduces operational costs.

- Scalable Configurations: From 500L/hr pilot systems to 20,000L/hr industrial setups.

- Durable Materials: 316L stainless steel, copper, or glass contact surfaces for corrosion resistance.

- Global Compliance: Pre-certified for FDA, ATEX, and ECOCERT requirements.

Tailored Solutions for Your Industry

🥃 Beverage Production

Preserve the nuanced flavors of whiskey, vodka, or rum with customizable copper or stainless steel columns. Our distillation systems feature precise temperature controls (±0.5°C) and CIP (Clean-in-Place) automation to minimize downtime.

🌿 Essential Oils & Aromatics

Protect delicate terpenes and esters using low-temperature vacuum distillation. Glass-lined components ensure zero contamination, while short-path designs boost yield by 30%.

💊 Pharmaceutical/Chemical

Meet pharmacopeia standards with GMP-compliant wiped-film molecular stills. All welds are 3D-inspected, and solvent recovery rates exceed 98%.

⚡ Biofuel & Ethanol

Cut energy costs by 25% with multi-column ethanol towers and biodiesel glycerol separators. Systems include heat recovery for closed-loop efficiency.

🏭 Water Desalination

Combat scaling in high-salinity environments using titanium-core multi-effect distillation (MED) units. Achieve <10 ppm TDS output with solar-compatible designs.

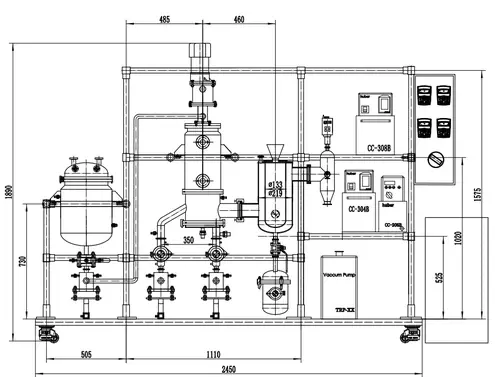

Technical Specifications

| Capacity | Materials | Automation | Certifications | Energy Use (kWh/L) |

|---|---|---|---|---|

| 500–20,000L/hr | 316L, Copper, Glass | PLC/HMI Controls | CE, ASME, ISO 9001 | 0.15–0.35 |

Trusted by Industry Leaders

- “Switching to Your Brand’s Commercial Distillation Equipment reduced our energy costs by 40% and improved rum flavor consistency.” — Caribbean Distillery

- “Their pharma-grade system helped us pass FDA audits on the first try.” — EU API Manufacturer

Global Certifications

✅ CE Marking ✅ ISO 9001 ✅ ASME BPVC ✅ FDA 21 CFR

End-to-End Support

- 24/7 Remote Monitoring: Real-time troubleshooting via IoT-enabled systems.

- 10-Year Warranty: Coverage for pressure vessels and core components.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do you preserve flavor in spirit production?

Our copper column options and precise congener control algorithms retain signature aromas while achieving 96% ABV purity.

Are your systems ATEX-certified for solvent handling?

Yes. Explosion-proof models include pressure relief valves and inert gas purging for ethanol or methanol processing.

Can you handle high-viscosity biodiesel byproducts?

Absolutely. Agitated thin-film evaporators prevent clogging, even with glycerol-rich feedstocks.

Do you offer solar-compatible desalination units?

Yes. MED systems integrate with solar thermal panels for off-grid water purification.

Contact Us

Email info@welloneupe.com for immediate Commercial Distillation Equipment assistance.