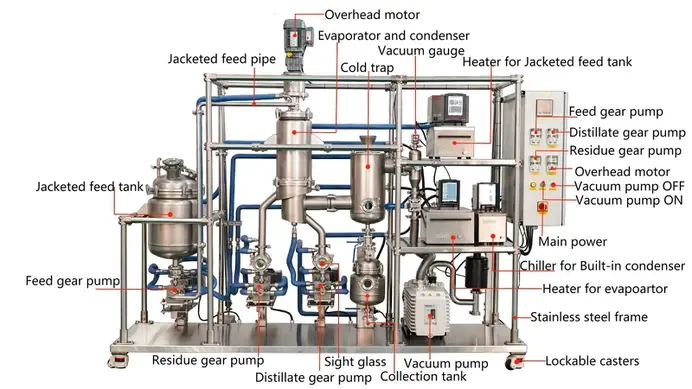

Stainless Steel Thin Film Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Most suitable for heat sensitive material

- Product Description

High-Purity Stainless Steel Thin Film Distillation Systems for Heat-Sensitive Compounds

Stainless Steel Thin Film Distillation systems are engineered to deliver unmatched precision in separating delicate compounds while preserving their integrity. Ideal for industries where thermal degradation is a critical concern, our systems combine 316L stainless steel construction, GMP/ISO compliance, and energy-efficient performance to meet rigorous standards. Whether you’re purifying APIs, refining essential oils, or processing biofuels, this technology ensures minimal heat exposure and maximum output purity.

Why Choose Our Thin Film Distillation Systems?

- Corrosion Resistance: Built with 316L/904L stainless steel for longevity in aggressive chemical environments.

- Ultra-Short Residence Time: Reduces thermal degradation of heat-sensitive materials like essential oils or APIs.

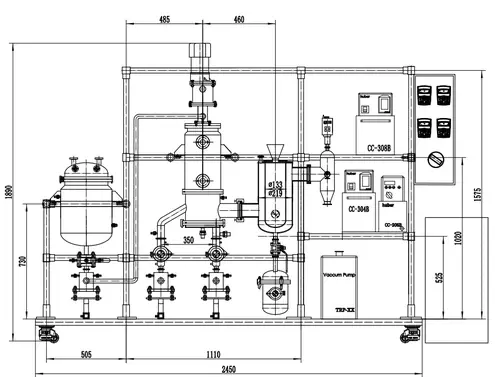

- Scalable Designs: Modular configurations for lab-scale R&D or industrial production (up to 5,000 L/hr).

- Energy Savings: Closed-loop systems cut energy use by up to 40% compared to traditional distillation.

Industries We Serve

Pharmaceuticals & Biotech

Purify active pharmaceutical ingredients (APIs) with ≤0.1% impurity levels. Compliant with FDA and GMP guidelines.

Essential Oils & Fragrances

Preserve volatile organic compounds (VOCs) and aromatic profiles using food-grade 316L surfaces.

Biodiesel & Renewable Energy

Process high-viscosity feedstocks efficiently with anti-clogging rotor designs and CIP compatibility.

Industrial Waste Treatment

Handle corrosive acids (e.g., HCl) using Hastelloy-clad components and zero-discharge systems.

Research & Pilot Plants

Benchtop units with adjustable RPM (10–1,200) and data-logging ports for scalable process testing.

Technical Excellence at Every Stage

- Material: 316L stainless steel (Hastelloy options for extreme corrosion).

- Vacuum Range: 0.1Pa for optimal separation of sensitive compounds.

- Certifications: CE, ISO, ASME, ATEX, FDA, ECOCERT.

- Control System: ABB automation for precise temperature (±1°C) and pressure management.

Outperform Traditional Methods

Traditional distillation often struggles with long processing times and uneven heat distribution. Our Stainless Steel Thin Film Distillation technology solves this with:

- Thinner Film Evaporation: Enhances surface area contact for faster separation.

- Anti-Fouling Mechanisms: Reduces downtime in high-solid waste applications.

- Hybrid Designs: Combine short-path and wiped-film techniques for multi-solvent recovery.

Real-World Success Stories

1. European Pharma Manufacturer: Achieved 99.9% API purity while cutting energy costs by 35%.

2. Southeast Asian Essential Oil Producer: Increased VOC retention by 22% using our short-path kits.

3. North American Biodiesel Plant: Boosted throughput to 4,800 L/hr with integrated pre-heat exchangers.

Custom-Built for Your Needs

Every system is tailored to your workflow:

- OEM/ODM Support: Modify rotor designs, capacity, or control interfaces.

- Global Technical Assistance: 24/7 multilingual support for installation and troubleshooting.

- 1-Year Warranty: Extended coverage available for industrial-scale setups.

Trusted by Regulated Industries

Our systems adhere to:

- Safety: ASME pressure vessel standards, ATEX explosion-proofing.

- Sustainability: ISO 14001-certified manufacturing processes.

- Transparency: Request a full compliance report via email.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does thin film design improve energy efficiency?

The ultra-thin evaporation layer reduces heating time, cutting energy use by up to 40%.

Can these systems handle high-viscosity biofuels?

Yes. Anti-clogging rotors and high-shear designs ensure smooth processing.

What maintenance is required?

Monthly CIP cycles and annual seal inspections keep systems running optimally.

Are lab-scale units available?

Absolutely. Our benchtop models feature adjustable RPM and real-time data tracking.

Contact Us

Email: info@welloneupe.com

Let’s build your Stainless Steel Thin Film Distillation precision solution!