Why Short Path Wiped Film Distillation Is the Best Choice for CBD and Hemp Oil Purification?

Are you struggling with low-purity CBD extracts that contain unwanted solvents, lipids, and impurities? Short Path Wiped Film Distillation offers the ultimate solution for achieving pharmaceutical-grade purity in your hemp oil products. This advanced purification technology combines continuous operation, precise temperature control, and minimal thermal degradation to deliver CBD concentrations exceeding 95%, transforming crude extracts into premium distillates that command higher market values and meet stringent industry standards.

Understanding Short Path Wiped Film Distillation Technology for Hemp Processing

Short Path Wiped Film Distillation represents a revolutionary approach to cannabinoid purification that addresses the critical challenges facing hemp processors. Unlike conventional batch distillation methods that expose heat-sensitive cannabinoids to prolonged high temperatures, this technology employs a continuous thin-film evaporation process where material residence time is measured in seconds rather than hours. The system operates under ultra-high vacuum conditions, typically below 0.001 mbar, which dramatically lowers the boiling points of target compounds, enabling distillation at temperatures that preserve the molecular integrity of delicate cannabinoids like CBD, THC, CBG, and CBN.

The Science Behind Molecular Separation in Cannabis Extracts

The fundamental principle underlying Short Path Wiped Film Distillation relies on the differential mean free path of molecules rather than traditional boiling point separation. When molecules evaporate from a heated surface under high vacuum, they travel in straight trajectories until colliding with another molecule or surface. Lighter molecules with longer mean free paths reach the internal condenser positioned just millimeters away, while heavier compounds fall back to the heated wall as residue. This molecular-level selectivity enables the separation of cannabinoids from waxes, pigments, and high-molecular-weight compounds that plague conventional extraction methods. The vertical cylindrical evaporator design incorporates precision-engineered wiper blades that continuously spread the viscous hemp oil into an ultra-thin film across the heated surface, creating maximum surface area per unit volume and facilitating instantaneous evaporation without thermal decomposition.

Multi-Stage Processing for Maximum Purity Achievement

Achieving pharmaceutical-grade CBD purity requires strategic multi-stage Short Path Wiped Film Distillation implementation. The first stage typically employs thin film evaporation to eliminate residual ethanol, water, and other volatile solvents, reducing their concentration below 500 ppm. This preparatory step is essential because solvent presence interferes with subsequent cannabinoid separation and can create safety hazards under vacuum conditions. The purified material then advances through two or three molecular distillation stages, each operating at progressively refined temperature and vacuum parameters. The second stage separates terpenes and light-end compounds, collecting them in an external chilled condenser while concentrating cannabinoids in the distillate fraction. The third stage performs final polishing, removing residual lipids, chlorophyll, and other contaminants to produce crystal-clear distillate with CBD purity exceeding 95%. This systematic approach enables processors to achieve three-pass purification where crude extracts containing only 30-50% CBD are transformed into premium distillates approaching 98% purity.

Critical Advantages of Short Path Wiped Film Distillation Over Traditional Methods

The superiority of Short Path Wiped Film Distillation becomes evident when examining its performance against conventional purification techniques. Traditional short-path batch systems require 4-8 hours per cycle and expose cannabinoids to elevated temperatures throughout this extended period, resulting in significant thermal degradation, oxidation, and isomerization reactions that diminish potency and alter cannabinoid profiles. In stark contrast, wiped film systems process material continuously with only 3-5 seconds of exposure to heated surfaces, virtually eliminating degradation while achieving throughput rates up to 100 kilograms per hour. This dramatic reduction in processing time not only preserves product quality but also transforms production economics.

Temperature Control Precision and Product Quality Protection

Individual temperature control at each distillation stage represents a game-changing capability for Short Path Wiped Film Distillation systems. The evaporator jacket temperature, internal condenser temperature, external condenser temperature, and feed line temperature can all be independently optimized for specific cannabinoid profiles and extract compositions. For CBD distillation, evaporator temperatures typically range from 150-180°C while the internal condenser maintains 70°C to prevent cannabinoid crystallization on the condenser surface. This precise thermal management prevents the formation of degradation products like CBN from THC oxidation or the conversion of CBD to THC through unwanted cyclization reactions that occur when material overheats. The jacketed piping design ensures material maintains optimal viscosity throughout the system, preventing blockages and facilitating smooth continuous operation without production interruptions.

Continuous 24-Hour Operation and Production Scalability

Short Path Wiped Film Distillation transforms hemp processing from a labor-intensive batch operation into a streamlined continuous production system. Once processing parameters are established, the equipment operates autonomously for extended periods without requiring vacuum breaks, material reloading, or extensive monitoring. Feed pumps deliver crude extract at precisely controlled rates while high-precision gear pumps continuously remove distillate and residue fractions, maintaining steady-state operation throughout production runs. This continuous processing capability enables manufacturers to operate around the clock, maximizing equipment utilization and dramatically reducing per-unit processing costs. The scalability advantage becomes particularly significant as production volumes increase—systems are available from laboratory scale handling 10 kg/hr to industrial installations processing 100+ kg/hr, allowing businesses to start small and expand capacity as market demand grows.

Equipment Design Features That Ensure Superior Hemp Oil Purification

Well One's Short Path Wiped Film Distillation systems incorporate sophisticated engineering elements that directly address the unique challenges of cannabinoid processing. The evaporator construction utilizes SS316L stainless steel, chosen specifically for its exceptional corrosion resistance when exposed to acidic cannabinoid extracts and cleaning solvents. The magnetic coupling drive system represents a critical innovation, transforming dynamic shaft seals into static seals that eliminate potential vacuum leaks while preventing product contamination from lubricants. This sealed design enables the system to maintain vacuum levels below 0.001 mbar consistently, which is essential for achieving low distillation temperatures and high separation efficiency.

Integrated Vacuum and Temperature Management Systems

The complete Short Path Wiped Film Distillation package integrates four independent heating circulation systems that provide precise thermal control across the evaporator, feed tank, material transfer lines, and condensers. High-capacity heaters ranging from 10 kW to 38 kW deliver rapid thermal response and stable temperature maintenance throughout production cycles. The vacuum system combines rotary vane pumps with roots booster pumps to achieve ultra-high vacuum levels while handling the continuous vapor load generated during distillation. Dedicated chilling units maintain external condensers at temperatures ranging from -80°C for terpene recovery to ambient for solvent collection, ensuring efficient condensation of all vapor fractions. The pressure isolation devices installed between distillation stages enable independent vacuum control at each level, optimizing separation efficiency while preventing cross-contamination between fractions.

Safety and Environmental Protection Features for Industrial Production

Industrial-scale Short Path Wiped Film Distillation demands rigorous safety engineering to protect operators and comply with environmental regulations. All electrical components meet UL explosion-proof standards, essential when processing flammable solvents and operating in potentially explosive atmospheres. The system incorporates multiple temperature sensors with automatic shutdown capabilities that activate if temperatures exceed safe operating limits, preventing thermal runaway conditions that could damage product or equipment. Pressure relief devices protect against vacuum failures, while solvent recovery systems capture and recycle volatile components rather than venting them to atmosphere. The modular operating platform design provides safe access for maintenance while sampling ports at each stage enable real-time quality monitoring without interrupting production. These comprehensive safety features ensure Short Path Wiped Film Distillation systems meet stringent industrial standards for pharmaceutical and food-grade production facilities.

Real-World Performance: CBD and Hemp Oil Purification Results

The practical performance of Short Path Wiped Film Distillation in CBD purification consistently exceeds alternative methods across multiple critical metrics. When processing winterized hemp crude containing 40-55% CBD, first-pass distillation typically elevates purity to 75-85%, while second-pass operation achieves 88-92% purity. Third-pass distillation produces premium pharmaceutical-grade material exceeding 95% CBD with negligible residual solvents, chlorophyll, waxes, and other contaminants. The recovery rate—the percentage of CBD in crude extract that successfully transfers to final distillate—typically ranges from 85-92%, significantly higher than the 60-70% recovery common with batch short-path systems. This superior recovery directly impacts profitability, as each percentage point improvement represents substantial value preservation in a market where pharmaceutical-grade CBD distillate commands premium pricing.

Economic Benefits and Return on Investment Analysis

The financial advantages of Short Path Wiped Film Distillation extend far beyond simple throughput improvements. The combination of higher recovery rates, superior purity, and continuous operation generates compelling economics for hemp processors. A mid-scale system processing 50 kg crude extract per day with 40% CBD content and 90% recovery produces approximately 18 kg of 95% CBD distillate daily. At market prices of $3,000-$5,000 per kilogram for pharmaceutical-grade distillate versus $1,500-$2,000 for crude extract, the value enhancement exceeds $30,000 per day. When factoring reduced labor costs from automated operation, lower energy consumption per kilogram processed compared to batch systems, and minimized product losses, the return on investment for Short Path Wiped Film Distillation equipment typically occurs within 6-12 months of operation. For larger industrial facilities processing hundreds of kilograms daily, the economic advantages become even more pronounced, justifying the higher initial capital investment.

Quality Consistency and Regulatory Compliance Advantages

Pharmaceutical and nutraceutical markets demand absolute consistency in cannabinoid content, residual solvent levels, and contaminant specifications across production batches. Short Path Wiped Film Distillation's continuous processing and precise parameter control deliver unprecedented batch-to-batch consistency that manual batch systems cannot match. The integrated sampling ports enable real-time monitoring and adjustment, ensuring every distillate fraction meets specifications before collection. This consistency proves invaluable when pursuing Good Manufacturing Practice (GMP) certification, USP dietary supplement standards, or pharmaceutical regulatory approvals. The comprehensive documentation capabilities, including temperature logs, vacuum records, and flow rate tracking, facilitate regulatory submissions and quality audits. Manufacturers producing CBD for clinical trials or pharmaceutical applications find that Short Path Wiped Film Distillation systems provide the validated, reproducible processing essential for regulatory acceptance.

Technical Specifications and System Configuration for Optimal Performance

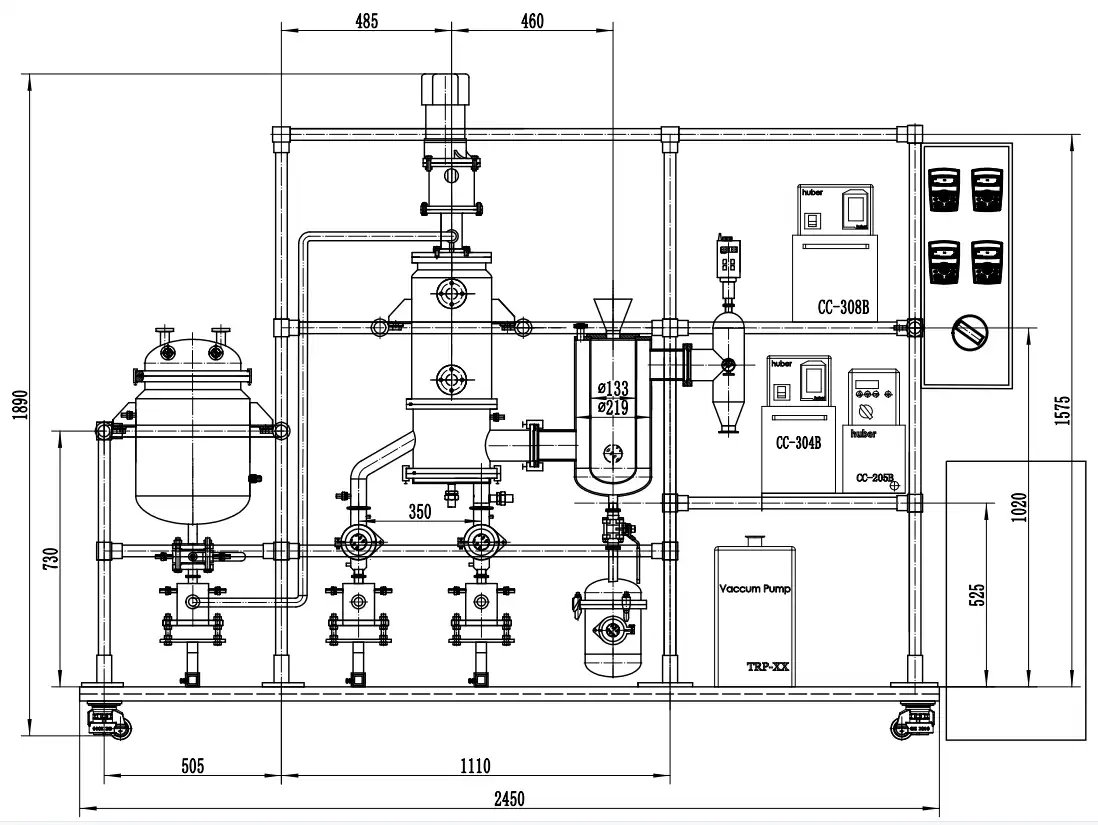

Well One's WMD-200-4 model exemplifies the sophisticated engineering incorporated into professional Short Path Wiped Film Distillation systems for hemp processing. The 2-square-meter evaporator area combined with 8-square-meter internal cooling area provides optimal vapor-handling capacity for continuous processing of viscous cannabinoid extracts. The 500mm evaporator diameter accommodates high-viscosity materials while maintaining the thin film thickness necessary for efficient heat transfer. High-precision gear pumps with variable frequency speed control deliver feed rates from 20-100 liters per hour, enabling processors to optimize throughput based on extract viscosity and desired purity targets. The magnetic sealing system eliminates shaft penetrations that plague traditional designs, ensuring leak-free vacuum integrity throughout extended production runs.

Auxiliary Equipment Integration for Complete Processing Solutions

Complete Short Path Wiped Film Distillation installations require coordinated auxiliary systems that match the main evaporator's specifications. The 200-liter jacketed feed tank incorporates dual sight glasses for visual monitoring and insulated ball valves for flow control, maintaining crude extract at optimal feeding temperature throughout processing. The main evaporator heating system delivers temperatures from ambient to 300°C with 38 kW heating capacity and 110 liters per minute circulation, ensuring rapid thermal response and stable temperature maintenance. Material insulation heating operates from ambient to 200°C with 10 kW capacity to prevent viscous cannabinoid solidification in transfer lines. The internal condenser heating and cooling system operates from -20°C to 200°C with dual 15 kW heating and 30 kW cooling capacity, providing flexibility for processing various cannabinoid profiles. External condenser chilling ranges from -80°C to ambient with staged cooling capacity, enabling efficient recovery of terpenes and volatile fractions. The dual vacuum system combining vane vacuum pumps and roots booster pumps maintains operating pressures below 0.001 mbar while handling continuous vapor loads.

Customization Options for Diverse Hemp Processing Applications

Well One's extensive customization capabilities enable Short Path Wiped Film Distillation systems tailored to specific processing requirements. Operators can select roller or wiper blade configurations based on material viscosity and desired residence time. Glass viewing ports allow visual monitoring of distillation progress, while automated controls minimize operator intervention. The modular design facilitates future expansion—processors can begin with single-stage installations and add subsequent stages as production volumes grow and purity requirements increase. Custom configurations accommodate specialized applications such as CBG isolation, minor cannabinoid concentration, or terpene fraction recovery. The flexible engineering approach ensures each system optimally addresses the unique characteristics of specific hemp cultivars, extraction methods, and target product specifications.

Conclusion

Short Path Wiped Film Distillation definitively establishes itself as the superior purification technology for CBD and hemp oil processing through its combination of continuous operation, minimal thermal degradation, precise temperature control, and exceptional recovery rates. The technology delivers pharmaceutical-grade distillates exceeding 95% purity while preserving valuable cannabinoids that batch systems destroy through prolonged heat exposure. With processing times measured in seconds rather than hours, industrial throughput capacity, and proven return on investment within months, this advanced purification method transforms hemp processing from an artisanal craft into a scalable manufacturing operation that meets the quality demands of pharmaceutical, nutraceutical, and premium consumer markets.

Cooperate with Xi'an Well One Chemical Technology Co., Ltd

Since 2006, Xi'an Well One Chemical Technology Co., Ltd, backed by Xi'an NewSet Chemical Equipment Technology Co., Ltd, has specialized in synthesis and purification separation equipment for pharmaceutical, food, petrochemical, essence, and fine chemicals industries. With a comprehensive 1500 m² office, 500 m² R&D laboratory, and 4500 m² manufacturing facility, the company delivers complete process development, equipment design, testing, and pilot services from laboratory to industrial scale. Their expert team ensures production capacity and product quality through 19 years of accumulated expertise in molecular distillation technology.

As China's leading Short Path Wiped Film Distillation factory, China Short Path Wiped Film Distillation supplier, and China Short Path Wiped Film Distillation manufacturer, Well One provides premium quality equipment with comprehensive OEM & ODM customization services. Every High Quality Short Path Wiped Film Distillation system undergoes rigorous testing and holds ISO9001, CE, and UL certifications before delivery. Whether you require laboratory-scale equipment for R&D, pilot systems for process optimization, or industrial installations processing hundreds of kilograms daily, Well One delivers China Short Path Wiped Film Distillation wholesale solutions with competitive Short Path Wiped Film Distillation prices and Short Path Wiped Film Distillation for sale options backed by lifetime technical support.

Contact Well One today at info@welloneupe.com to discuss your CBD and hemp oil purification requirements. Their experienced engineers will analyze your specific processing needs, recommend optimal system configurations, and provide detailed proposals including technical specifications, pricing, and installation timelines. Don't let inefficient purification methods limit your hemp business potential—discover how Well One's Short Path Wiped Film Distillation technology can elevate your product quality, increase recovery rates, and maximize profitability. Request your free consultation and join the growing number of hemp processors worldwide who trust Well One for their molecular distillation equipment needs.

References

1. Valizadehderakhshan, M., et al. "Optimization of Wiped-Film Short Path Molecular Distillation for Recovery of Cannabinoids from Cannabis Oil Using Response Surface Methodology." Industrial Crops and Products, Volume 194, 2023.

2. Fregolente, P. B. L., et al. "Response Surface Methodology Applied to Optimization of Process Conditions for Tocopherol Concentration in Soybean Deodorizer Distillate by Molecular Distillation." Journal of Food Engineering, Volume 78, Issue 4, 2007.

3. Ketenoglu, O. and A. Tekin. "Molecular Distillation: An Alternative Process to Improve the Quality of Olive Pomace Oil." European Journal of Lipid Science and Technology, Volume 117, 2015.

4. Calzolari, D., et al. "High Added-Value Compounds from Cannabis threshing Residues." Industrial Crops and Products, Volume 108, 2017.