What is the use of stainless steel distiller?

When your production line faces product contamination, inconsistent quality, and high operational costs, you need a reliable solution that addresses these critical challenges head-on. Stainless Steel Molecular Distillation offers advanced separation technology that purifies heat-sensitive compounds without thermal degradation, ensuring superior product quality and maximized yield in pharmaceutical, food, and chemical industries.

Core Applications of Stainless Steel Molecular Distillation Technology

Stainless Steel Molecular Distillation represents a breakthrough in separation science, utilizing the difference in molecular mean free paths rather than boiling point differences. This innovative approach enables the purification of thermally sensitive materials that would otherwise degrade under conventional distillation conditions. The technology operates under ultra-high vacuum conditions, typically achieving 0.1Pa, which allows molecular-level separation at significantly lower temperatures than traditional methods.

Industrial Purification Solutions

The pharmaceutical industry relies heavily on Stainless Steel Molecular Distillation for synthesizing high-purity compounds. Polyethylene glycol production exemplifies this application, where microchannel reactors combined with molecular distillation achieve single molecular weight distribution impossible with traditional batch reactors. Squalene purification demonstrates another critical application, where multi-stage molecular distillation removes fatty acids and esters to achieve 98% purity. This level of precision makes Stainless Steel Molecular Distillation indispensable for pharmaceutical excipient manufacturing.

Food Grade Processing Applications

In food processing, Stainless Steel Molecular Distillation technology transforms crude materials into premium products. Fish oil purification showcases the technology's superiority, achieving 70% recovery rates compared to traditional methods' 16%. The system separates EPA and DHA ethyl esters through four-stage molecular distillation, producing concentrated omega-3 products with excellent color, minimal fishy odor, and low peroxide values. Tea oil deacidification represents another breakthrough application, where molecular distillation removes free fatty acids without damaging beneficial components or generating harmful waste.

Advanced Material Processing

The petrochemical industry utilizes Stainless Steel Molecular Distillation for waste lubricating oil regeneration and base oil production. Multi-stage distillation systems separate light components from heavy fractions, recovering multiple high-quality base oil products with different viscosity properties. This fraction-cutting capability through series connection enables comprehensive resource recovery while maintaining product specifications. The technology also excels in epoxy resin purification, removing low boiling point substances and hetero groups to obtain low total chlorine epoxy resin.

Technical Advantages of Stainless Steel Molecular Distillation Systems

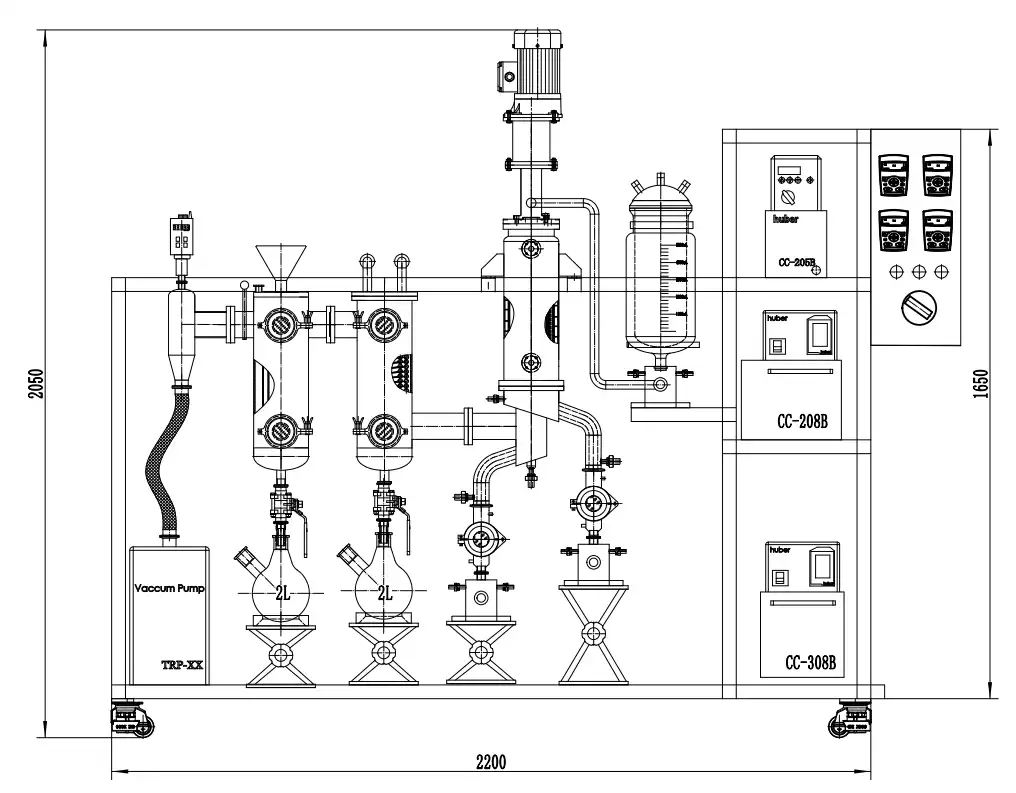

Modern Stainless Steel Molecular Distillation equipment incorporates precision-engineered components that ensure reliable operation and consistent results. The 316 stainless steel construction provides exceptional corrosion resistance and maintains product purity without material interaction. ABB control systems deliver precise temperature and pressure regulation, critical for optimal separation efficiency. High vacuum systems reaching 0.1Pa create ideal conditions for molecular-level separation without thermal stress.

Superior Component Integration

KingLai vacuum ball valves enhance system vacuum integrity, ensuring stable operation throughout extended production runs. SEW brand motors with UL certification provide safe, reliable mechanical performance. The wiper and roller assemblies utilize imported PTFE or graphite materials, offering outstanding chemical resistance and minimal friction during operation. SKF ceramic bearings eliminate lubrication requirements, preventing contamination while delivering exceptional wear resistance. Magnetic sealing technology surpasses traditional mechanical seals by improving vacuum integrity and reducing maintenance requirements.

Enhanced Separation Efficiency

The condensation system represents a critical performance factor in Stainless Steel Molecular Distillation technology. Coil and liquid nitrogen cold traps dramatically enlarge the condensation area, improving separation efficiency while protecting the vacuum pump from contamination. This design enables processing of sensitive materials like rose essential oil, where traditional methods cause molecular rearrangement and oxidation. The system maintains low operating temperatures that preserve volatile aromatics and bioactive compounds, delivering high-purity products suitable for pharmaceutical and cosmetic applications.

Operational Excellence and Workflow Optimization

Professional operation of Stainless Steel Molecular Distillation systems requires systematic procedures that maximize efficiency and product quality. The workflow begins with proper injector installation and receiving bottle positioning, followed by cooling water circulation activation. Scraper rotor adjustment to specified speeds ensures optimal film formation on the evaporating surface. Vacuum pump engagement occurs only after liquid nitrogen reaches required levels, typically half the condensate column volume.

Process Control Methodology

Pressure optimization represents a critical operational parameter in Stainless Steel Molecular Distillation systems. Fine-tuning valves adjust vacuum levels to below 0.5 mbar, creating ideal conditions for molecular separation. Injection speed control through valve adjustment maintains consistent feed rates throughout processing. The system accommodates continuous material addition through samplers, enabling uninterrupted production during extended runs. Safety protocols include systematic shutdown sequences that gradually relieve pressure before heating element disengagement, protecting both product quality and equipment integrity.

Maintenance and Cleaning Protocols

Equipment longevity and consistent performance depend on proper maintenance procedures for Stainless Steel Molecular Distillation systems. Cleaning protocols utilize anhydrous ethanol introduced through the injection system, leveraging residual heat for effective residue removal. Regular replacement of receiving bottles and thorough system flushing prevent cross-contamination between product batches. The modular design facilitates component access for inspection and maintenance, minimizing downtime while ensuring long-term operational reliability.

Industry-Specific Applications and Case Studies

The essence and fragrance industry demonstrates exceptional benefits from Stainless Steel Molecular Distillation technology. Plant oil purification systems complete vegetable oil refinement while recovering solvents like n-hexane, methanol, and ethanol for reuse. Falling film evaporators remove light components, followed by stripping tower purification that reduces residual solvent content below 10ppm. This comprehensive approach meets stringent purity requirements for cosmetic and fragrance applications.

Specialty Chemical Processing

Monoglyceride purification exemplifies fine chemical applications of Stainless Steel Molecular Distillation technology. Glycerin monostearate production involves esterification of glycerin and hydrogenated oil, followed by two-stage molecular distillation that removes glycerol, free fatty acids, diglycerides, and triglycerides. The resulting high-purity monoglycerides serve as emulsifiers, plasticizers, and lubricants across multiple industries. Lanolin extraction and derivative production showcase another specialized application, where molecular distillation separates components for modification into polyoxyethylene lanolin, acetyllanolin, and other high-performance products.

Conclusion

Stainless Steel Molecular Distillation technology delivers unmatched purification capabilities for heat-sensitive materials across pharmaceutical, food, petrochemical, and specialty chemical industries, combining ultra-high vacuum operation with precision engineering to achieve superior product quality and operational efficiency.

Cooperate with Xi'an Well One Chemical Technology Co., Ltd

Since 2006, Xi'an Well One Chemical Technology Co., Ltd has specialized in synthesis and purification separation equipment, backed by comprehensive R&D capabilities and manufacturing excellence. Our facility encompasses 1500 m² office space, 500 m² research laboratory, and 4500 m² production factory equipped with CNC machining centers and advanced processing machinery. We deliver molecular distillation devices from experimental scale to industrial production, ensuring optimal capacity and quality.

Our competitive advantages position us as your ideal China Stainless Steel Molecular Distillation factory and China Stainless Steel Molecular Distillation supplier partner. Premium quality standards utilize CE, ISO, UL, and SGS certified components ensuring reliability. Comprehensive OEM and ODM support includes custom 3D animation designs tailored to specific applications. Our China Stainless Steel Molecular Distillation manufacturer capabilities span single-stage, dual-stage, and three-stage configurations. High Quality Stainless Steel Molecular Distillation systems feature 316 stainless steel construction with ABB control systems. As a leading China Stainless Steel Molecular Distillation wholesale provider, we offer competitive factory-direct pricing with one-year warranty coverage. Our Stainless Steel Molecular Distillation for sale portfolio serves pharmaceutical, food processing, new materials, petrochemical, essence, and fine chemical industries. Contact our expert team at info@welloneupe.com for Stainless Steel Molecular Distillation price quotations and technical consultations to optimize your purification processes today.

References

1. Perry, R.H., Green, D.W., & Maloney, J.O. (1997). Perry's Chemical Engineers' Handbook. McGraw-Hill Professional.

2. Batistella, C.B., & Maciel, M.R.W. (2006). Molecular Distillation: Rigorous Modeling and Simulation for Recovering Vitamin E from Vegetable Oils. Applied Biochemistry and Biotechnology.

3. Lutisan, J., Cvengros, J., & Micov, M. (2002). Heat and Mass Transfer in the Evaporating Film of a Molecular Evaporator. Chemical Engineering Journal.

4. Cvengros, J., & Lutisan, J. (1995). Mean Free Path of Molecules on Molecular Distillation. Chemical Engineering Journal and the Biochemical Engineering Journal.