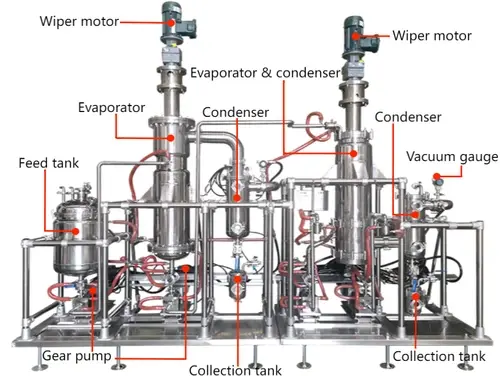

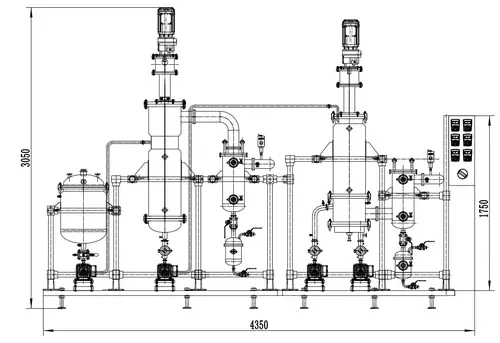

Lab Agitated Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for maple oil.

- Product Description

Lab Agitated Thin Film Evaporator | Scalable, GMP-Ready & Precision-Controlled

Achieve 95%+ solvent recovery with a Lab Agitated Thin Film Evaporator, process viscosities up to 50,000 cP, and ensure full traceability for Pharma, Chemicals, Cannabis, and Food R&D.

Why Choose Our Lab Agitated Thin Film Evaporator?

The product is engineered for precision separation and concentration of heat-sensitive materials. Whether you’re purifying APIs, recovering terpenes, or treating corrosive waste, our system combines scalability (0.1–5 m² evaporation area) with GMP-ready compliance to meet strict industry standards. With smart IoT controls and modular designs, it adapts seamlessly from lab trials to full production.

Key Specifications

| Parameter | Details |

|---|---|

| Evaporation Area | 0.1–2 m² (expandable to 5 m²) |

| Temperature Range | -30°C to 200°C (±1°C precision) |

| Vacuum Performance | <1 mbar |

| Agitation Speed | 100–1500 RPM (variable wiper geometry) |

| Materials | 316L SS (pharma/food), Hastelloy C-22, Titanium, PTFE-coated parts |

| Certifications | CE, ISO 9001/13485, ATEX, 3-A Sanitary, ASME BPE |

Solve Industry-Specific Challenges

🧪 Pharmaceutical & Biotech

- Purify APIs with ≤0.1% residual solvents.

- GMP/GLP validation support (IQ/OQ/PQ documentation included).

🌿 Cannabis/CBD Extraction

- Preserve 98%+ cannabinoid purity with ≤-20°C condensation.

- Explosion-proof motors (ATEX/NEC Class I Div 1 compliant).

🏭 Specialty Chemicals

- Devolatilize polymers at 0.5–5.0 kg/hr·m² rates.

- Hastelloy C-22 builds resist acids, chlorides, and radioactive streams.

🥄 Food & Essential Oils

- Recover 85%+ aroma compounds with 316L electropolished surfaces (Ra ≤0.4μm).

- CIP/SIP cycles validated for 3-A Sanitary Standards.

☢️ Government Research

- Zirconium/Ta-coated surfaces for nuclear waste R&D.

- ITAR/EAR export control compliance.

Outperform Competitors

1️⃣ Patented Agitation Technology

Our Lab Agitated Thin Film Evaporator scraped-surface rotor achieves 30% higher throughput for viscous fluids (>10,000 cP) versus traditional wiped-film evaporators.

2️⃣ Zero-Revalidation Scaling

Upgrade from lab to production without requalification. All modules include FDA/EU audit-ready logs.

3️⃣ 21 CFR Part 11-Compliant Controls

Store batch recipes, auto-generate audit trails, and monitor purity in real-time via ABB PLC systems.

Trusted Globally

- Clients: Top 10 Pharma Companies, USDA-Certified Food Processors, Leading Biofuel Labs.

- Certifications: CE, ISO 9001/13485, PED 2014/68/EU, UL 1203 (Explosion-Proof).

- Proven Data: 95% solvent recovery efficiency, ≤2% terpene loss in CBD trials.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How is GMP compliance ensured for pharma use?

Our product includes embedded PAT sensors and validation protocols for FDA/EMA audits.

Can it handle high-viscosity polymers?

Yes. Variable rotor geometries process fluids up to 50,000 cP without fouling.

What explosion-proof certifications apply?

ATEX Directive 2014/34/EU, UL 1203, and NEC Class I Div 1 for cannabis/CBD facilities.

How are food-grade surfaces maintained?

CIP cycles achieve <10 CFU/swab with 316L SS electropolished to Ra ≤0.4μm.

What scaling options exist?

Modular designs allow capacity expansion from 0.1 m² to 5 m² with plug-and-play integration.

Contact Us

✅ 24/7 Technical Support

Contact Us Today: Email info@welloneupe.com for Lab Agitated Thin Film Evaporator configuration support.