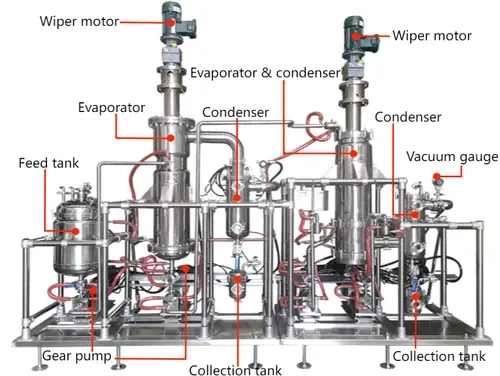

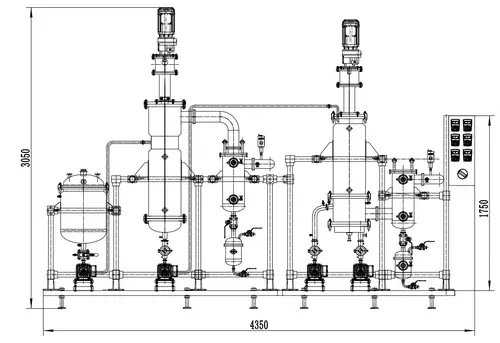

Industrial Wiped Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for monoglyceride.

- Product Description

Industrial Wiped Film Evaporators: Precision Separation for Demanding Industries

Looking for a reliable solution to handle high-viscosity, heat-sensitive, or corrosive materials? Our Industrial Wiped Film Evaporator combines cutting-edge thin-film technology with customizable engineering to deliver unmatched separation efficiency. Ideal for industries like pharmaceuticals, chemicals, and food processing, our systems minimize thermal degradation while maximizing yield. With certifications including CE, ISO, and GMP compliance, we ensure your operations meet global standards without compromising on energy efficiency or scalability.

Why Choose Our Industrial Wiped Film Evaporators?

- Gentle Processing: Preserve sensitive compounds (APIs, essential oils) with low-temperature evaporation.

- Corrosion Resistance: Built with 316L stainless steel, Hastelloy, or titanium for harsh chemical environments.

- GMP Compliance: Sanitary designs with CIP/SIP capabilities for pharmaceutical and food-grade applications.

- Energy Savings: Patented rotor-scraper systems reduce energy use by up to 30% vs. traditional evaporators.

- Scalable Solutions: Modular configurations for small-batch R&D or high-volume industrial production.

Industry-Specific Applications

🏭 Chemicals & Petrochemicals

Devolatilize polymers, recover high-boiling solvents, and process heavy residues with corrosion-resistant designs.

💊 Pharmaceuticals

Concentrate APIs, recycle solvents under vacuum, and ensure GMP compliance with full documentation support.

🍎 Food & Nutraceuticals

Purify essential oils, retain nutrients in plant extracts, and meet FDA/EC1935 standards with hygienic evaporators.

🌍 Waste Recycling

Reduce hazardous sludge volume and recover solvents using explosion-proof, high-solids-capable systems.

⛽ Oil & Gas

Treat biodiesel, refine heavy oils, and withstand acidic components with an Industrial Wiped Film Evaporator made of high-temperature-stable alloys.

Technical Specifications

- Materials: 316 stainless steel, Hastelloy C-276, titanium

- Certifications: CE, ISO 9001, ASME, GMP

- Vacuum Range: Up to 0.1Pa

- Control Systems: ABB automation for precise temperature/pressure management

- Customization: OEM/ODM support for feed systems, heating surfaces, and rotor configurations

Trusted Compliance & Global Support

All systems adhere to ASME, PED, and FDA standards. Our 24/7 technical team provides:

- Onsite installation supervision

- Operator training programs

- Rapid spare parts delivery

Case Study Snapshot

Client Challenge: A European pharma producer needed to concentrate heat-sensitive APIs without degradation.

Our Solution: A GMP-compliant wiped film evaporator with CIP capabilities.

Results: 95% solvent recovery rate, 40% faster processing vs. rotary evaporators.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does thin-film technology prevent thermal degradation?

The evaporator’s rotor creates a thin, turbulent film, reducing residence time and exposure to high temperatures.

Can this system handle abrasive petrochemical residues?

Yes—Hastelloy or titanium wipers ensure durability in corrosive environments.

What energy-saving features are included?

Heat recovery systems and optimized vacuum pumps cut operational costs by up to 30%.

Is CIP/SIP compatibility available for pharma use?

Absolutely. Our sanitary designs include validated cleaning protocols.

Contact Us

Ready to Optimize Your Industrial Wiped Film Evaporator Process?

📧 Contact Us: info@welloneupe.com