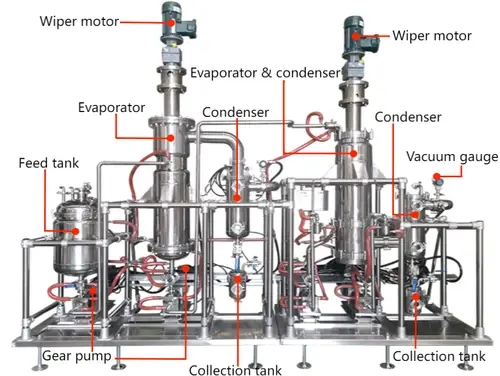

Industrial Thin Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for fish oil.

- Product Description

Industrial Thin Film Evaporators: Precision Evaporation for Demanding Applications

When processing heat-sensitive, viscous, or corrosive materials, Industrial Thin Film Evaporators deliver unmatched efficiency. Our systems combine short residence times (3-10 seconds) with precise temperature control, making them ideal for pharmaceutical purification, solvent recovery, and food-grade concentration. With 1,000+ installations across 30 countries, we’ve optimized thin-film evaporation mechanics to reduce energy use by 30% while maintaining GMP, FDA, and ASME compliance.

Why Choose Our Thin Film Evaporation Systems?

Core Engineering Advantages

- Rapid, Gentle Processing: Low-temperature operation (40–90°C) preserves bioactive compounds in APIs, essential oils, and nutraceuticals.

- Material Versatility: Constructed in 316L stainless steel, Hastelloy, or titanium for corrosive feeds like HCl recovery or aggressive solvents.

- Scalable Designs: Modular units from 1㎡ (pilot R&D) to 40㎡ (full production) with vacuum levels down to 0.1Pa.

- Self-Cleaning Mechanics: Rotating wipers prevent fouling in high-solid (up to 25%) or viscous streams (50,000 cP).

Pharma & Chemical

- Solvent recycling yields >98% purity

- CIP/SIP-ready systems with EHEDG-certified surfaces

Food & Essential Oils

- Electropolished, FDA-compliant evaporators

- 40% faster citrus oil concentration vs. rotary evaporators

Environmental

- ATEX-certified units for hazardous waste streams

- Achieve 95% sludge volume reduction

R&D

- Adjustable parameters: residence time, shear rates, vacuum

- Leasing options for academic institutions

Trusted by Global Leaders

Certifications: CE, ISO 9001, ASME Section VIII, FDA 21 CFR, EC1935

Performance-Driven Results

| Application | Throughput | Energy Savings | Purity Improvement |

|---|---|---|---|

| Vitamin E Recovery | 2,000 L/h | 35% | 99.2% |

| Waste Solvent Reprocessing | 800 L/h | 28% | 97.8% |

| Fish Oil Concentration | 1,500 L/h | 32% | 98.5% |

Global Support, Local Responsiveness

- 24/7 Industrial Thin Film Evaporator Technical Hotline: Multilingual engineers resolve issues within 4 hours.

- On-Site Training: Learn optimal scraping blade adjustment, vacuum optimization.

- Spare Parts Network: 18 regional hubs guarantee ≤48h delivery for critical components.

Flexible Procurement Options

- Production Units: Standard lead time 5-7 weeks, expedited slots available

- Distributor Programs: Volume-based pricing, white-label branding

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do peoducts prevent thermal degradation in pharmaceuticals?

Our evaporators limit material exposure to heat through rapid, uniform thin-film flow – ideal for temperature-sensitive APIs.

Can I upgrade an existing evaporator with your thin-film technology?

Yes! We retrofit conventional units with customized wiping systems and automation controls.

What food safety certifications do your systems hold?

All food-contact surfaces comply with FDA, EC1935, and 3-A Sanitary Standards.

Do you provide performance guarantees?

Yes – 100% throughput and purity validation during factory acceptance testing.

Contact Us

Optimize Your Industrial Thin Film Evaporator Process Today:

Contact Our Engineers: info@welloneupe.com