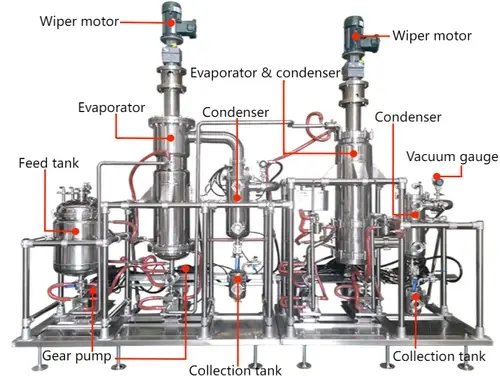

Industrial Short Path Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for seabuckthorn seed oil.

- Product Description

Industrial Short Path Evaporator: Precision Evaporation for Demanding Industries

When efficiency and purity matter, the Industrial Short Path Evaporator stands as a game-changer for pharmaceutical, chemical, and food manufacturers. Designed to handle heat-sensitive materials with unmatched precision, our systems combine short-path distillation technology with energy-smart engineering. Whether you’re refining essential oils, recovering solvents, or concentrating high-value compounds, this compact, GMP-ready solution ensures minimal thermal degradation while cutting operational costs by up to 40%.

Why Choose Our Industrial Short Path Evaporator?

1. Smarter Technology for Higher Purity

Unlike traditional evaporators, our short-path systems operate at lower temperatures, protecting delicate compounds from damage. A rotating scraper creates an ultra-thin film of material, accelerating evaporation while reducing energy use. Compatible with corrosive substances like acids or aggressive solvents, we offer 316L stainless steel, Hastelloy, or titanium builds to match your process needs.

2. Built for Your Industry

- Pharma & Nutraceuticals: ATEX-certified models with solvent recovery compliant with FDA 21 CFR Part 11.

- Specialty Chemicals: Explosion-proof designs for hazardous environments and viscous materials.

- Waste Treatment: Automated self-cleaning modules that reduce sludge volume by 60% and ensure EPA emissions compliance.

3. Plug-and-Play Integration

Our evaporators arrive pre-configured for seamless integration with ABB or Siemens PLCs, featuring vertical stackable designs to save floor space. Pre-piped utility connections (steam, cooling water) simplify installation, while IoT-ready sensors enable real-time performance tracking.

Certifications That Build Trust

Every Industrial Short Path Evaporator meets global benchmarks:

- CE, ISO 9001, and UL certifications for safety

- REACH/RoHS-compliant materials

- GMP-ready documentation for pharmaceutical audits

Modular Designs, Scalable Results

Scale operations without downtime using our modular setups:

- Single to Three-Stage Configurations: Optimize separation efficiency for complex mixtures.

- Vacuum Systems: Achieve 0.1Pa vacuum levels for rapid, low-temperature evaporation.

- Retrofit Kits: Upgrade legacy systems with AI-driven controls and predictive maintenance alerts.

Lifecycle Support You Can Rely On

We protect your investment with:

- 24/7 Remote Monitoring: Proactively address issues before they escalate.

- Global Spare Parts Network: 72-hour emergency delivery for pumps, seals, and sensors.

- Operator Training: Hands-on sessions covering safety, maintenance, and troubleshooting.

Ready to Ship, Ready to Perform

- 1-Year Warranty: Backed by Lloyd’s Register insurance.

- Export-Ready: CIQ certificates, multilingual manuals, and legalized invoices.

- Flexible Orders: OEM/ODM support for batches from 5 to 100+ units.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does this evaporator improve solvent recovery efficiency?

By maintaining high vacuum levels (0.1Pa), our systems lower boiling points, reducing thermal stress on solvents and cutting energy use by up to 40% compared to rotary evaporators.

Are your systems compatible with SCADA integration?

Yes. Our evaporators work with Siemens, Allen-Bradley, and ABB PLCs via standardized OPC-UA protocols.

What corrosion-resistant materials are available?

We offer 316L stainless steel, titanium, and Hastelloy builds for aggressive chemicals or high-salinity environments.

Do you provide multilingual technical support?

Absolutely. Our team supports English, Spanish, Mandarin, and Arabic, with manuals available in 8 languages.

How quickly can I get spare parts?

Critical components like condensers ship within 72 hours from our hubs in the US, Germany, and Singapore.

Contact Us

Transform your Industrial Short Path Evaporator process today.

Email info@welloneupe.com to request a tailored quote or schedule a live demo.