Recover solvents (DMF, DMSO) or remove heavy metals from waste streams using a Dual Stage Wiped Film Evaporator. Explosion-proof configurations meet ATEX standards.

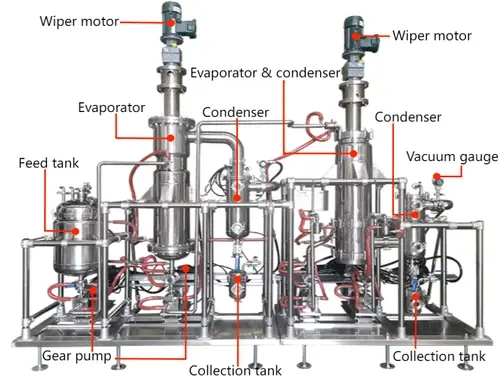

Dual Stage Wiped Film Evaporator

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8)Mainly used for MCT oil.

- Product Description

Dual-Stage Wiped Film Evaporators – Precision Separation for Demanding Industries

Maximize yield, minimize thermal degradation, and scale production with our Dual Stage Wiped Film Evaporator customizable two-stage evaporation technology.

Why Choose a Dual Stage Wiped Film Evaporator?

If you’re processing heat-sensitive, viscous, or high-value materials, a prodcut offers unmatched precision. By combining two evaporation stages in one system, it achieves higher purity levels and energy efficiency than single-stage units. Ideal for industries like pharmaceuticals, food processing, and petrochemicals, this technology ensures gentle separation, reduced operational costs, and scalability from lab trials to full production.

Key Benefits at a Glance

- Higher Purity & Throughput: Dual-stage separation removes impurities more effectively, boosting product quality.

- Low-Temperature Efficiency: Protects APIs, essential oils, and heat-sensitive compounds from degradation.

- Energy Recovery: Integrated systems reuse waste heat, cutting energy costs by up to 30%.

- Compliance Ready: Meets GMP, FDA, and ATEX standards for regulated industries.

- Easy Scalability: Modular designs adapt to R&D, pilot, or large-scale production needs.

Technical Specifications

| Parameter | Details |

|---|---|

| Capacity | 5 L/hr to 5,000 L/hr |

| Operating Temperature | 50°C to 300°C (adjustable per stage) |

| Vacuum Range | Down to 0.001 mbar |

| Materials | 316L SS, Hastelloy, Glass-Lined Options |

| Custom Add-Ons | Automated Controls, CIP/SIP, IoT Integration |

Where It Excels: Industry Applications?

1. Pharmaceuticals & Biotechnology

Purify APIs, recover solvents, and refine cannabinoids with ≤1 ppm residue. Our GMP-compliant design ensures FDA audit readiness.

2. Food & Essential Oils

Concentrate omega-3s, vitamin E, or terpenes without compromising aroma or nutritional value. Food-grade 316L stainless steel guarantees safety.

3. Petrochemicals & Chemicals

Distill monomers, oligomers, or high-boiling-point additives. Corrosion-resistant materials handle aggressive byproducts.

4. Environmental Recycling

5. EPC Projects

Deploy turnkey systems for biodiesel or specialty chemicals. Skid-mounted designs reduce installation time by 50%.

Trusted by Industry Leaders

> “Reduced our API purification time by 40% while achieving 99.8% purity.”

> – Global Pharma Co.

> “Zero downtime in 3 years of continuous solvent recovery.”

> – Petrochemical Plant, Germany

Why Partner With Us?

- 15+ Years of Expertise.

- 500+ Global Installations: Proven success across 30 countries.

- End-to-End Support: From design to maintenance, we’re with you at every step.

- 24/7 Technical Assistance.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does a dual-stage design improve separation efficiency?

By processing material twice in one cycle, it removes more impurities than single-stage units, ideal for high-purity outputs like pharmaceuticals.

Can it handle viscous food-grade materials?

Yes. Our rotor-scraper system maintains a thin, even film for gentle evaporation—perfect for essential oils or omega-3 concentrates.

What materials are used for corrosive chemicals?

We offer Hastelloy and glass-lined options to resist acids, solvents, and high-salinity environments.

How does it reduce operational costs?

Energy recovery systems reuse waste heat, while automated controls optimize solvent use and minimize downtime.

What’s the lead time for a 1,000 L/hr unit?

14–18 weeks, with expedited options for urgent projects.

Contact Us

Email info@welloneupe.com for a Dual Stage Wiped Film Evaporator tailored solution or live demo.

Optimize your separation process with precision engineering. Let’s build your next-generation evaporation system together.