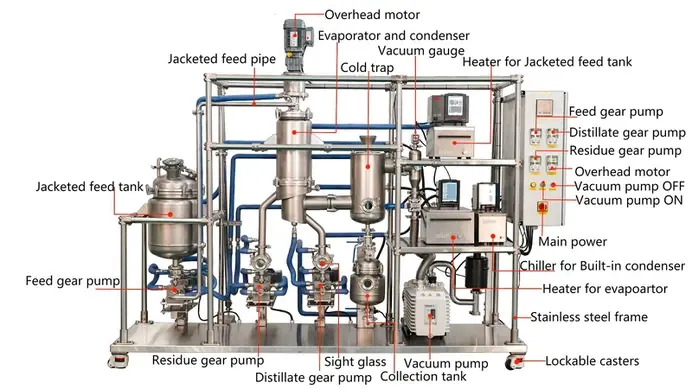

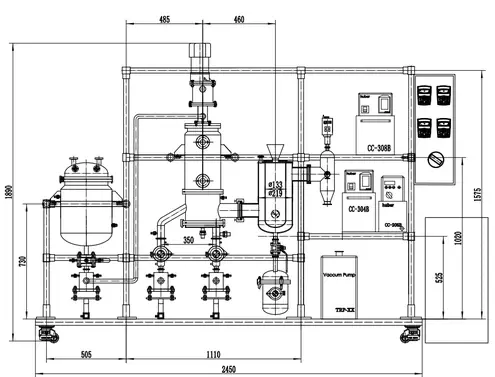

Short Path Molecular Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Visual operation,extraction | distillatio

- Product Description

Precision Short Path Molecular Distillation Systems for Heat-Sensitive Compounds

Achieve >99% Purity with Energy-Efficient, Scalable Separation Solutions

When processing delicate compounds like pharmaceuticals, essential oils, or CBD extracts, Short Path Molecular Distillation offers unmatched precision. Our systems minimize thermal degradation while ensuring GMP, ISO, and CE compliance—ideal for industries demanding ultra-pure outputs. Whether you’re scaling R&D trials or optimizing full production, our modular designs adapt to your exact needs.

Why Choose Our Technology?

1. Gentle Separation for Sensitive Materials

- Low-Temperature Operation: Maintain critical compound integrity with 50°C–150°C ranges.

- Short Residence Time: <1-second vapor path preserves volatile aromatics in essential oils and terpenes.

- Multi-Stage Fractionation: Precisely isolate compounds by molecular weight using adjustable wiped-film rollers.

2. Industry-Tailored Configurations

- Pharmaceuticals: Batch-traceable systems with FDA-grade 316L stainless steel surfaces and CIP/SIP validation.

- Essential Oils: Cold traps retain 95%+ terpenes; borosilicate glass prevents oxidation.

- CBD Processors: Reduce THC to <0.3% with solvent recovery rates exceeding 90%.

- Nutraceuticals: Nitrogen-purged chambers limit oxygen ingress to <5ppm for oxidation-prone oils.

3. Technical Excellence

- Vacuum Range: 0.001–5 mbar for precise separation control.

- Throughput: Scale from 5L/hr (pilot) to 500L/hr (production) with stackable units.

- Materials: Corrosion-resistant 316L SS, PTFE, or glass-lined options.

| Feature | Our System | Traditional Methods |

|---|---|---|

| Thermal Degradation | <2% Loss | 15–40% Loss |

| Solvent Use | 70% Less | High Consumption |

| Scalability | Modular Expand | Fixed Setup |

Customization for Your Workflow

- Modular Designs: Add fraction collectors, cold traps, or PAT sensors.

- Material Options: Choose from glass, 316L SS, or Hastelloy C-22 for harsh chemicals.

- Short Path Molecular Distillation Control Systems: ABB PLCs with touchscreen interfaces for real-time adjustments.

Trusted Globally

- Certifications: CE, ISO 9001, UL, SGS, NSF.

- Compliance: Meets FDA 21 CFR Part 11, EHEDG, and ASME standards.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How do you prevent thermal damage in heat-sensitive compounds?

Our short vapor path and precise temperature control (±0.5°C) ensure materials spend <1 second at elevated temperatures.

Can systems handle viscous materials like resins?

Yes. Specialized wiped-film rotors process feedstocks up to 50,000 cP without fouling.

What’s the lead time for a custom system?

Standard configurations ship in 8–12 weeks, including on-site commissioning and staff training.

Do you provide scalability from R&D to production?

Absolutely. Pilot trials start with 100ml batches, with guaranteed scale-up parameters for seamless transitions.

How is cross-contamination prevented?

Integrated cold traps and CIP/SIP cycles ensure <10ppm residue between batches.

Contact Us

Optimize Your Short Path Molecular Distillation Process Today:

📩 Contact Us: Email info@welloneupe.com for a free consultation.