12 Inch Molecular Distillation

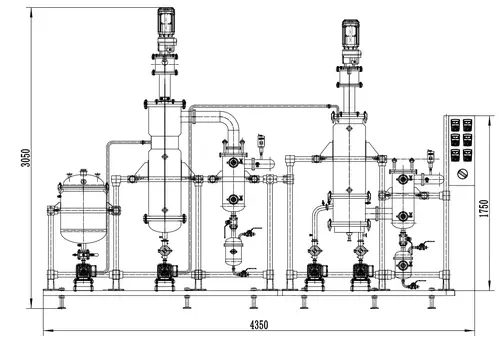

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) stock available for fast delivery within 7days

- Product Description

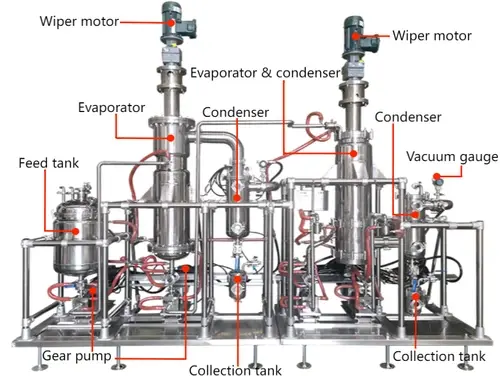

12 Inch Molecular Distillation Systems: Precision Separation for Demanding Industries

When refining heat-sensitive compounds like pharmaceuticals, essential oils, or biofuels, every degree matters. Our 12 Inch Molecular Distillation technology combines short-path efficiency with industrial-scale throughput, delivering >99.9% purity while preserving delicate molecules. Designed for FDA, GMP, and ISO-compliant facilities, these systems scale seamlessly from pilot batches to 5,000 L/day production—without compromising precision.

Why Choose Our 12 Inch Distillation Systems?

✅ Low-Temperature Processing

Operate at <50°C to protect APIs, terpenes, and omega-3 oils from thermal degradation.

✅ Short Residence Time

Minimize compound exposure to heat with rapid 2-5 minute cycles.

✅ Scalable Throughput

Adjust from 100 L/hr (R&D) to 2,000 L/hr (full production) using modular evaporators.

✅ Zero Cross-Contamination

316L stainless steel and PTFE seals ensure odorless, residue-free outputs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Evaporation Surface | 12-inch diameter |

| Vacuum Range | <0.001 mbar |

| Temperature Control | 20°C–200°C (±0.5°C) |

| Materials | 316L SS, borosilicate glass, PTFE |

| Compliance | FDA, CE, GMP, ISO 9001, ASME |

Industry Applications

Pharmaceuticals

Isolate lipid nanoparticles for mRNA vaccines or purify heat-sensitive APIs with 12 Inch Molecular Distillation, achieving ≤5 ppm solvent residues.

Essential Oils

Preserve 98%+ terpenes in CBD extracts while removing pesticides at <80°C.

Biofuels

Convert waste cooking oil to ASTM-grade biodiesel with 30% lower energy use than conventional stills.

Nutraceuticals

Remove fishy odors from omega-3 concentrates while retaining DHA/EPA integrity.

How We Outperform Competitors?

- Throughput: 3x higher output than 6-inch systems.

- Energy Use: 20% lower power consumption via heat recovery tech.

- Versatility: Handle viscosities up to 50,000 cP (e.g., cannabis resin).

Trusted by Global Leaders

- PharmaCo reduced API degradation by 95% during monoclonal antibody purification.

- EssentialOil Inc. doubled winterization yield for full-spectrum hemp extracts.

Certified Quality

- Certifications: CE, ISO 9001, UL, SGS.

- Warranty: 1 year + lifetime technical support.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

Q: Can this system meet GMP standards for vaccine production?

Yes. All pharma-grade units include CIP/SIP capabilities and 21 CFR Part 11-compliant data logging.

Q: What’s the lead time for a custom-configured product unit?

Standard units ship in 8 weeks. Custom setups (e.g., ATEX-rated) require 10-12 weeks.

Q: How do you prevent fouling in high-viscosity feeds?

Our helical wiper design ensures uniform thin-film distribution, even with tar-like biomass.

Contact Us

Ready to Optimize Your 12 Inch Molecular Distillation Process?

Email:info@welloneupe.com

Request a free throughput analysis today!