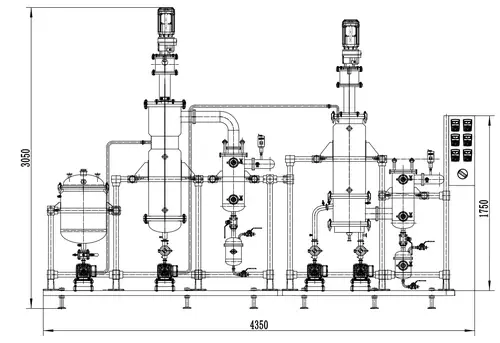

Dual Stage Thin Film Distillation

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Gear pump material charging,flow 3L~15L/H

- Product Description

Dual Stage Thin Film Distillation Systems | High-Purity, Energy-Efficient Separation

Achieve precision separation with our Dual Stage Thin Film Distillation technology, engineered to maximize purity while minimizing energy costs. Ideal for heat-sensitive compounds in pharmaceuticals, specialty chemicals, and food processing, this system combines two optimized evaporation stages to deliver 99.9% purity with 30% lower energy consumption than traditional methods.

Why Choose Dual Stage Thin Film Distillation?

✅ 40% Less Thermal Stress

Protect delicate compounds like APIs or natural extracts with reduced heat exposure.

✅ GMP/CE/ASME-Certified Build

Corrosion-resistant materials (SS316L, Hastelloy) meet strict hygiene and safety standards.

✅ Scalable for Any Throughput

Modular designs handle 3L/hr lab trials to 10,000L/hr industrial production.

✅ 30% Energy Savings

Patented heat recovery slashes operating costs without compromising speed.

Industry-Specific Solutions

🧪 Chemicals & Petrochemicals

- Break azeotropes efficiently

- Recover solvents at ≤0.1ppm residual levels

- Handle viscosities up to 50,000 cP

💊 Pharmaceuticals & Biotech

- cGMP-compliant API purification

- Fully automated CIP/SIP cycles

- Real-time purity monitoring (PAT integration)

🍊 Food & Essential Oils

- Preserve 98%+ volatile aromas

- Alcohol removal under 35°C

- USDA-approved cleaning protocols

♻️ Environmental Recycling

- 98% solvent recovery from hazardous waste

- pH 1-14 compatibility

- Explosion-proof configurations

How It Outperforms Alternatives?

| Feature | Dual Stage Thin Film | Rotary Evaporation | Short-Path Distillation |

|---|---|---|---|

| Max Purity | 99.9% | 95% | 99% |

| Temp Range | 30°C – 200°C | 40°C – 150°C | 50°C – 300°C |

| Energy Use (kW/hr) | 18 | 25 | 22 |

| CIP Compatibility | Yes | No | Limited |

Real-World Results

Case Study 1: Pharmaceutical API Producer

Challenge: 15% yield loss due to thermal degradation in single-stage systems.

Solution: Dual Stage Thin Film Distillation with ≤45s residence time.

Result: 99.5% purity in single pass, $220K/year energy savings.

Case Study 2: Citrus Oil Processor

Challenge: 20% aroma loss during concentration.

Solution: Low-temperature (32°C) dual-stage evaporation.

Result: ECOCERT organic certification maintained, throughput doubled.

Trusted Worldwide

🔹 Certifications: CE, ISO 9001/14001,

🔹 Materials Traceability: Full MTRs provided

🔹 Warranty: 1 year + lifetime technical support

OEM & Bulk Order Benefits

- White-Label Options: Add your branding

- Regional Compliance Kits: Pre-configured for EU, ASEAN, or NA standards

- Training Included: On-site operator certification

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does the dual-stage design prevent flavor loss in food extracts?

By completing evaporation in two rapid steps (≤60s total), heat-sensitive terpenes are preserved through controlled vacuum levels.

Can I upgrade from single-stage to dual-stage?

Yes! Our modular systems allow retrofitting with ≤3 days downtime.

What maintenance is required?

Annual seal replacements and monthly CIP cycles – we provide checklists.

Do you offer pilot trials?

Test your material in our GMP facility with real-time data logging.

Contact Us

Contact Our Engineers for Dual Stage Thin Film Distillation: