Factory Price Wiped Film Evaporator Stainless Steel Molecular Distillation Distiller

Are you struggling with thermal degradation of heat-sensitive materials during conventional distillation processes? Factory Price Wiped Film Evaporator Stainless Steel Molecular Distillation Distiller offers an innovative solution that operates under extreme vacuum conditions, enabling separation at temperatures far below normal boiling points. This Stainless Steel Molecular Distillation technology protects valuable compounds from thermal damage while achieving exceptional purity levels, making it indispensable for pharmaceutical, food, and fine chemical applications where product integrity cannot be compromised.

Understanding Stainless Steel Molecular Distillation Technology

Stainless Steel Molecular Distillation represents a revolutionary advancement in separation technology that fundamentally differs from traditional distillation methods. Rather than relying on boiling point differences, this technology exploits the variance in molecular mean free paths between different substances. The Stainless Steel Molecular Distillation system operates under ultra-high vacuum conditions, typically achieving pressures as low as 0.1 Pa, which creates an environment where molecules can travel from the heated evaporating surface to the condensing surface without collision. This collision-free molecular pathway enables separation of thermally sensitive compounds that would otherwise decompose under conventional distillation temperatures.

The Science Behind Molecular Mean Free Path Separation

The operational principle of Stainless Steel Molecular Distillation hinges on the molecular mean free path concept, which describes the average distance a molecule travels before colliding with another molecule. In high vacuum environments, lighter molecules with longer mean free paths can reach the condenser surface positioned at a specific distance from the evaporator, while heavier molecules with shorter mean free paths fall back into the residue. This selective molecular transport mechanism enables precise separation based on molecular weight and structure rather than thermal properties alone, providing superior control over fractionation processes compared to conventional distillation techniques.

Key Technical Specifications of Advanced Systems

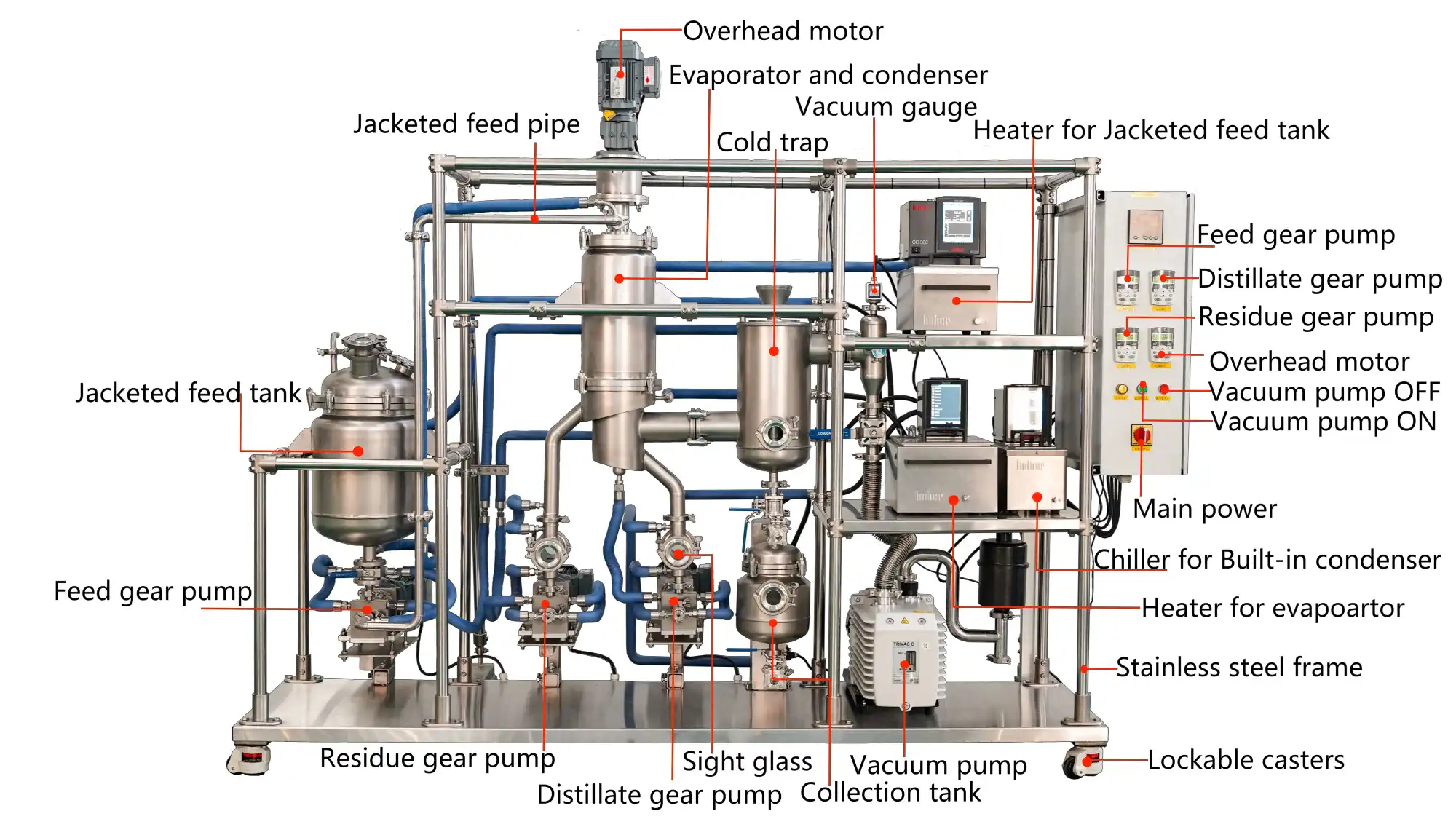

Modern Stainless Steel Molecular Distillation equipment incorporates sophisticated engineering features that maximize separation efficiency and operational reliability. Systems constructed from 316 stainless steel provide exceptional corrosion resistance and maintain material purity throughout processing. ABB control systems deliver precise temperature and vacuum regulation, while UL-listed electrical components ensure safety compliance across international markets. The wiped film evaporator design employs PTFE or graphite wipers that continuously spread thin liquid films across heated surfaces, optimizing heat transfer efficiency and minimizing residence time. Multi-stage configurations enable sequential purification steps, with single-stage, dual-stage, and three-stage systems available to match specific separation requirements and production capacities.

Industrial Applications of Stainless Steel Molecular Distillation Systems

Pharmaceutical Industry Purification Solutions

Stainless Steel Molecular Distillation has become instrumental in pharmaceutical manufacturing, particularly for synthesizing and purifying compounds requiring stringent purity standards. Polyethylene glycol production benefits significantly from molecular distillation technology, which achieves narrow molecular weight distributions impossible with traditional batch reactors. The process enables synthesis of single-distribution PEG with dispersity indices below 1.05, critical for pharmaceutical excipient applications. Squalene purification represents another vital pharmaceutical application, where multi-stage Stainless Steel Molecular Distillation removes fatty acids and ester impurities from crude extracts, achieving final product purities reaching 98% while recovering valuable solvents and reducing production costs.

Food Industry Processing Excellence

The food industry relies extensively on Stainless Steel Molecular Distillation for extracting and refining nutritionally valuable components from natural sources. Fish oil purification exemplifies this application, where the technology separates EPA and DHA ethyl esters with recovery rates reaching 70%, dramatically surpassing the 16% recovery of conventional methods. Four-stage molecular distillation systems process crude fish oil through esterification, washing, dehydration, and sequential distillation stages to produce concentrated omega-3 products containing 80% total DHA and EPA content. The resulting products exhibit superior color, minimal fishy odor, and low peroxide values. Tea oil deacidification presents another critical application, where Stainless Steel Molecular Distillation removes free fatty acids without damaging valuable nutritional components or generating the excessive waste associated with traditional alkaline refining methods.

Advanced Materials and Chemical Processing

Stainless Steel Molecular Distillation technology serves essential roles in new materials and petrochemical industries, addressing complex separation challenges that conventional methods cannot solve. Epoxy resin purification employs two-stage molecular distillation to remove low boiling point impurities in the first stage while separating light and heavy components in the second stage, producing high-purity, low total chlorine epoxy resins with precisely controlled properties. Waste lubricating oil regeneration demonstrates the technology's environmental value, where multi-stage systems fractionate deteriorated oils into high-quality base oils with varying viscosity profiles suitable for lubricant blending. The process removes additives, oxidation products, and contamination while recovering usable fractions, converting waste streams into valuable resources.

Technical Features and Operational Advantages

Premium Component Integration

Factory Price Wiped Film Evaporator Stainless Steel Molecular Distillation Distiller systems incorporate carefully selected components that ensure reliable long-term performance. KingLai vacuum ball valves maintain system vacuum integrity, preventing air ingress that would compromise separation efficiency. SEW brand UL-listed motors provide dependable drive power for scraper mechanisms operating at speeds up to 400 rpm. SKF ceramic bearings eliminate lubrication requirements while delivering superior wear resistance and chemical compatibility. Magnetic sealing systems replace traditional mechanical seals, improving vacuum integrity while reducing maintenance requirements and extending service intervals. Coil and liquid nitrogen cold traps enlarge condensation surface area, enhance separation efficiency, and protect vacuum pumps from contamination.

Workflow Optimization and Operation

Proper operational procedures maximize Stainless Steel Molecular Distillation system performance and product quality. The workflow begins with installing injection equipment and receiving bottles, followed by initiating cooling water circulation. Scraper rotors activate at specified speeds while liquid nitrogen fills condensate columns to required levels before vacuum pump startup. Pressure optimization through fine-tuning valves establishes optimal vacuum conditions, typically below 0.5 mbar for molecular distillation applications. Feed rate adjustment through injector valves controls material throughput while maintaining optimal film thickness on evaporating surfaces. Continuous operation permits additional material feeding through sampling ports, enabling uninterrupted processing. System shutdown requires careful pressure relief procedures and thorough cleaning protocols using anhydrous ethanol to maintain equipment cleanliness and prevent cross-contamination between production runs.

Customization Capabilities and Manufacturing Excellence

OEM and ODM Solutions

Xi'an Well One Chemical Technology Co., Ltd. specializes in developing customized Stainless Steel Molecular Distillation solutions tailored to specific client requirements and application demands. The company's design team creates detailed 3D models and animations visualizing custom configurations before manufacturing begins, ensuring precise alignment with client specifications. Customized solutions range from compact systems with glass feeding tanks and external condensers for space-constrained installations to large-scale dual-stage configurations processing square meters of evaporating surface area. All electrical accessories carry UL certifications and integrate seamlessly with premium auxiliary equipment from manufacturers like Huber, delivering turnkey systems ready for immediate production deployment.

Comprehensive Research and Development Support

Beyond equipment manufacturing, the company maintains extensive research and development capabilities supporting clients from initial concept through full-scale production. A 500 square meter R&D laboratory equipped with pilot-scale Stainless Steel Molecular Distillation systems enables feasibility studies, process development, and optimization testing using actual client materials. The technical team provides process development services that establish optimal operating parameters, including temperatures, pressures, feed rates, and stage configurations. Laboratory and pilot testing validates separation performance and product specifications before committing to industrial-scale equipment investments. This comprehensive service approach ensures production equipment delivers guaranteed capacity and quality performance based on empirical experimental results.

Conclusion

Factory Price Wiped Film Evaporator Stainless Steel Molecular Distillation Distiller represents cutting-edge separation technology essential for modern pharmaceutical, food, and chemical processing industries. The systems deliver exceptional purification performance for thermally sensitive compounds while maintaining product integrity and maximizing recovery yields through advanced engineering and precision manufacturing.

Cooperate with Xi'an Well One Chemical Technology Co., Ltd

Since 2006, Xi'an Well One Chemical Technology Co., Ltd. has specialized in synthesis and purification separation equipment, backed by Xi'an NewSet Chemical Equipment Technology Co., Ltd. With comprehensive facilities including a 1500 m² office, 500 m² R&D laboratory, and 4500 m² manufacturing factory, the company delivers complete process development, equipment design, testing, and pilot services. Their expert team produces molecular distillation devices from laboratory to industrial scale across pharmaceutical, food, new materials, petrochemical, essence, and fine chemical industries.

Are you ready to enhance your purification processes with high-quality Stainless Steel Molecular Distillation technology? As a leading China Stainless Steel Molecular Distillation factory, China Stainless Steel Molecular Distillation supplier, and China Stainless Steel Molecular Distillation manufacturer, we offer competitive China Stainless Steel Molecular Distillation wholesale pricing on Stainless Steel Molecular Distillation for sale. Our Stainless Steel Molecular Distillation price reflects exceptional value, delivering High Quality Stainless Steel Molecular Distillation with CE, ISO, UL, and SGS certifications, OEM & ODM customization, one-year warranty, and direct factory supply advantages. Contact us at info@welloneupe.com to discuss your specific requirements and receive detailed technical proposals tailored to your applications.

References

1. Perry, Robert H., and Green, Don W. "Perry's Chemical Engineers' Handbook: Distillation." McGraw-Hill Education, Eighth Edition.

2. Batistella, Cesar B., and Maciel, Maria Regina Wolf. "Molecular Distillation: Rigorous Modeling and Simulation for Design and Operation." Brazilian Journal of Chemical Engineering.

3. Hickman, Kenneth C.D. "High-Vacuum Short-Path Distillation: A Review of Applications." Chemical Engineering Progress.

4. Lutisan, Jozef, and Cvengros, Jan. "Mean Free Path of Molecules in Molecular Distillation." Chemical Engineering Journal.