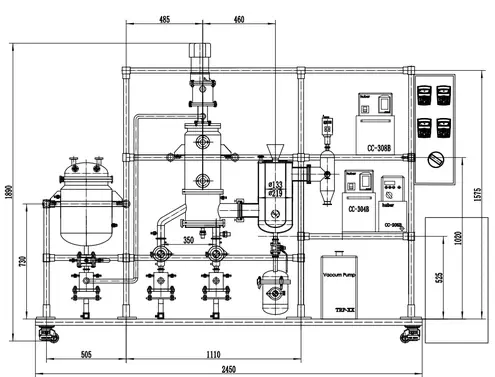

Short Path Distillation Equipment

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) 14inch hotsale

- Product Description

High-Purity Short Path Distillation Equipment for Precision Separation

Engineered for Pharma, Natural Extracts, Biofuels, and R&D Applications

When purity and precision matter, Short Path Distillation Equipment delivers unmatched separation efficiency. Designed for industries where heat-sensitive compounds demand gentle processing, our systems achieve ultra-high vacuum levels (≤0.001 mbar) to preserve molecular integrity. Whether you’re refining cannabinoids, isolating fragrances, or recycling biofuels, this technology ensures consistent results with minimal thermal degradation.

Why Choose Our Distillation Systems?

✅ Ultra-High Vacuum Efficiency

Precisely separate compounds with boiling point differences as low as 5°C, ideal for pharmaceutical APIs or terpene-rich essential oils.

✅ Scalable Modular Design

Transition seamlessly from lab-scale R&D (100mL/hr) to industrial production (50L/hr) with interchangeable glassware and ISO-KF flanges.

✅ GMP-Ready Construction

Built with 316L stainless steel and borosilicate glass for corrosion resistance, compliance, and repeatable performance.

✅ Energy-Saving Operation

Reduce energy costs by 30% with integrated heat recovery and low-temperature distillation cycles.

Tailored Solutions for Your Industry

Pharmaceuticals & Biotechnology

- Achieve >99% purity for oncology drugs, vitamins, or solvents.

- GMP-compliant designs with full validation documentation.

Essential Oils & Natural Extracts

- Preserve volatile terpenes and CBD with rapid cooling and <1°C temperature variance.

- USDA-certified systems for organic processing.

Biofuels & Renewable Energy

- Process viscous feedstocks like algae oil at 100+ L/hr throughputs using Short Path Distillation Equipment.

- Ruggedized systems for 24/7 operation with automated residue handling.

Cosmetics & Fragrances

- Isolate delicate aroma molecules without thermal breakdown.

- Compact benchtop units for small-batch R&D.

Technical Specifications

| Feature | Specification |

|---|---|

| Evaporation Surface | 0.1㎡ to 5㎡ Configurations |

| Throughput | 100mL/hr to 50L/hr |

| Materials | Borosilicate Glass 3.3, PTFE Seals |

| Vacuum Range | ≤0.001 mbar |

| Certifications | CE, ASME, ISO 9001, RoHS |

Real-World Success Stories

- 98.7% Purity in Pharma: A Swiss client purified an oncology compound with zero cross-contamination.

- 40% Yield Boost: An Indonesian essential oil producer doubled output using our modular short-path system.

- Zero Waste in Biofuels: A German pilot plant recycled 95% of feedstock with automated residue handling.

Short Path vs. Alternatives

| Feature | Short Path | Wiped Film | Rotary Evaporation |

|---|---|---|---|

| Purity | Up to 99.9% | 90-95% | 80-85% |

| Throughput | 50L/hr | 200L/hr | 10L/hr |

| Energy Use | Low | Moderate | High |

Trusted by Global Innovators

- 15+ Years of refining distillation technology

- 200+ Systems installed across 30 countries

- 24/7 Support with remote performance monitoring

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does Short Path Distillation preserve heat-sensitive compounds?

By operating at ultra-low pressures (≤0.001 mbar), our systems lower boiling points, allowing gentle separation even for fragile molecules like terpenes or vitamins.

Can I scale from lab trials to full production?

Yes! Our modular product supports interchangeable components for seamless scaling—from 100mL/hr prototypes to 50L/hr industrial batches.

What certifications do your systems hold?

All units meet CE, ASME, and ISO 9001 standards. Pharma-grade systems include GMP compliance documentation.

Contact Us

Ready to Elevate Your Short Path Distillation Equipment Purification Process?

Contact our engineers at info@welloneupe.com to discuss custom configurations.