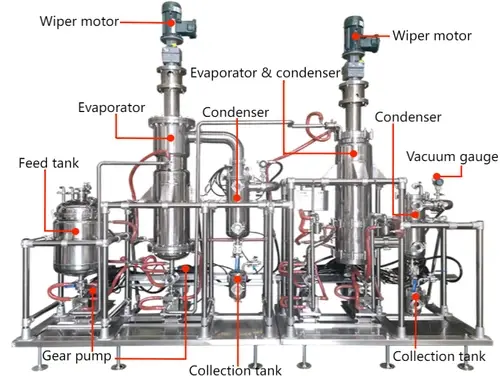

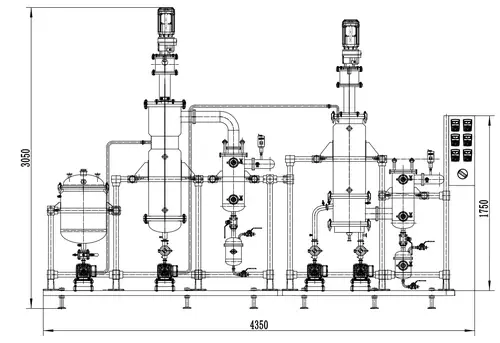

2 Stage Wiped Film Molecular Distillation Machine

2)Supply Single stage, Dual stage, Three stage.

3)High vacuum degree: 0.1Pa.

4)Control system: ABB.

5)Material:316 stainless steel.

6)OEM & ODM support.

7)Warranty:1 Year.

8) Overseas installation & traning service

- Product Description

2 Stage Wiped Film Molecular Distillation Machine: Precision Purification for Heat-Sensitive Compounds

Achieve ultra-high purity, scalability, and thermal protection for APIs, cannabinoids, essential oils, and specialty chemicals with our 2 Stage Wiped Film Molecular Distillation Machine. Designed for industries demanding precision separation, this advanced system combines dual-stage efficiency with energy-saving innovation to optimize your production outcomes.

Why Choose Our Dual-Stage Distillation Technology?

- Enhanced Separation Efficiency: Process complex mixtures in two sequential stages for higher purity (up to 99.9%) and reduced residuals.

- Low-Temperature Operation: Protect heat-sensitive compounds like terpenes, vaccines, or cannabinoids from thermal degradation.

- Customizable Configurations: Adjustable vacuum levels (≤0.001 mbar), temperature ranges (50°C–300°C), and feed rates to match your material’s needs.

- GMP & ISO Compliance: Built with 316L stainless steel and validated for pharmaceutical, food-grade, and chemical applications.

Optimized for Your Industry

Pharmaceuticals & APIs

Isolate high-purity active pharmaceutical ingredients (APIs) with cGMP-compliant designs, minimizing thermal stress on sensitive molecules.

Essential Oils & Botanicals

Preserve volatile aromatics and terpenes using low-temperature evaporation and rapid cooling systems.

CBD & Cannabis Processing

Remove solvents, contaminants, and THC traces while retaining cannabinoid potency in broad-spectrum extracts.

Specialty Chemicals

Achieve precise molecular weight fractionation for polymers, agrochemicals, and petrochemical derivatives.

Technical Highlights

| Specification | Details | |

|---|---|---|

| Evaporation Area | Customizable (Lab to Industrial) | |

| Material Compatibility | 316L SS, Glass-Lined, Hastelloy | |

| Throughput Capacity | 5–5000 L/h (Scalable) | |

| Certifications | CE, ISO 9001, GMP, ATEX, FDA-Compliant |

Trusted by Global Innovators

- Pharma Case Study: A European manufacturer achieved 99.8% API purity with 30% faster processing using our dual-stage system.

- CBD Success Story: A North American processor reduced residual solvents to <5 ppm, meeting strict EU/US regulatory limits.

How We Stand Out?

Unlike single-stage or short-path distillation systems, our 2 Stage Wiped Film Molecular Distillation Machine offers:

- Higher Yield: Thin-film evaporation maximizes material recovery.

- Lower Energy Costs: Patented rotor design reduces energy use by 40%.

- Future-Proof Flexibility: Upgrade with additional stages or automation as your needs evolve.

Surface Finish & Vacuum Degree

Factory Strength

Exhibition

Packaging & Transportation

FAQ

How does dual-stage design improve separation?

The first stage removes low-boiling-point compounds, while the second stage operates under higher vacuum for precise separation of complex mixtures.

Can it handle viscous materials?

Yes. Our optimized wiping system prevents residue buildup, even with high-viscosity extracts like cannabis distillate or polymer blends.

What maintenance is required?

Routine checks on seals, wipers, and vacuum pumps ensure consistent performance. We provide 24/7 support and spare parts globally.

Is scaling down possible for R&D?

Absolutely. Pilot-scale systems maintain the same precision as industrial units, ideal for process optimization.

Contact Us

Ready to Transform Your 2 Stage Wiped Film Molecular Distillation Machine Purification Process?

For bulk pricing or technical queries, contact our experts at info@welloneupe.com.